Breakthrough Catalyst Technology by Sinokle: Enhancing Ozone Oxidation Performance & Economic Viability

Ozone Advanced Catalytic Oxidation (OZAC)

Ozone advanced catalytic oxidation is an efficient water or exhaust treatment technology. It utilizes catalysts to enhance the decomposition of ozone (O3), generating highly reactive free radicals (e.g., ·OH), which rapidly degrade organic pollutants. The performance of the catalyst directly determines oxidation efficiency and economic viability.

1. Core Functions of the Catalyst

A. Promote Ozone Decomposition: Accelerate the conversion of O3to ·OH (hydroxyl radicals). With an oxidation potential of 2.8V—much higher than ozone (2.07V)—·OH enables non-selective degradation of the vast majority of organic compounds.

B. Reduce Reaction Energy Consumption: Decrease ozone dosage and shorten reaction time.

C. Broaden Applicable pH Range: Certain catalysts operate efficiently under neutral or weakly alkaline conditions, overcoming the limitation of ozone-only oxidation (which typically performs better under acidic conditions).

2. Key Factors in Catalyst Design

A. Active Site Density: Metal valence states (e.g., Mn4+) and oxygen vacancy concentration directly influence ozone decomposition efficiency.

B. Stability: Resistance to leaching (especially under acidic conditions) and poisoning (e.g., by Cl-, SO42- in wastewater).

C. Mass Transfer Efficiency: Porous structures or core-shell designs (e.g., TiO₂@CeO₂) optimize the contact between pollutants and active sites.

3. Key Technological Innovations of Sinokle's Independently Developed Catalysts

A. Multi-component Catalytic System: Incorporates various transition metal oxides (including noble metals) as catalytic components. Through extensive experiments and engineering validation, the material ratio is optimized to ensure excellent adaptability to different types of wastewater while delivering high catalytic activity.

B. Precision Temperature-Controlled Sintering Technology: Utilizes multi-stage precision temperature-controlled sintering. While preserving the activity of catalytic components, it effectively reduces production energy consumption and catalyst leaching rate during operation, preventing secondary pollution.

C. High-Performance Support Design: Adopts high-activity materials as catalyst supports. The porous structure provides a large specific surface area, and the incorporation of non-leachable catalytic components enhances the catalyst's stability. The support features high mechanical strength and a long service life.

D. Efficient Activation Energy Reduction: Significantly lowers the reaction activation energy, enabling deep oxidation and maximizing the removal of organic pollutants.

E. Enhanced Ozone Decomposition: Accelerates the self-decomposition of ozone in water, increasing the concentration of ·OH (hydroxyl radicals) generated. This improves ozone oxidation efficiency by 2–5 times compared to ozone-only oxidation.

F. Atomic Layer Deposition (ALD) Modification: Employs atomic layer deposition technology for catalyst modification. The resulting support exhibits superhydrophilicity, preventing catalyst fouling, scaling, and clogging, thus enabling long-cycle stable operation.

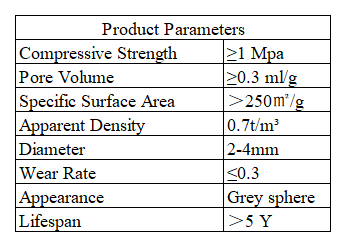

4. Parameters of Sinokle's Catalyst