CDOF Technology: Integrated Solution for Efficient Wastewater Treatment on Offshore Oil Platforms

1. Sources of Wastewater from Offshore Oil Production Platforms

Wastewater from offshore oil production platforms primarily originates from various links in the production process, including but not limited to: oily wastewater discharged from production separators, treated effluent from electric dehydrators, and other oily wastewater generated during the daily operation of the platform. These wastewaters can be further categorized into multiple types based on oil content, chemical composition, suspended solid concentration, and other parameters. A common characteristic is that they all contain a certain amount of petroleum-based pollutants, posing potential threats to the marine environment.

2. Characteristics of Wastewater from Offshore Oil Production Platforms

High oil content with a wide particle size distribution of oil droplets, ranging from large free oil particles to tiny emulsified oil droplets.

Presence of significant residues of chemical agents (e.g., corrosion inhibitors, scale inhibitors), which increases the difficulty of treatment.

Limited space availability requires compact and efficient treatment equipment to adapt to the special environment of offshore platforms.

3. Key Challenges in Treating Wastewater from Offshore Oil Production Platforms

a. Low oil-water separation efficiency, especially for the removal of tiny emulsified oil and dissolved oil.

b. Easy generation of oily sludge during the treatment process, increasing the burden of subsequent disposal.

c. Complex and variable offshore environments impose high requirements on the stability and corrosion resistance of treatment equipment.

4. Traditional Treatment Processes and Their Limitations

Physical-chemical combined treatment methods are mostly adopted, including steps such as inclined plate oil separation, hydrocyclone separation, and walnut shell filtration.

a. Multiple treatment stages result in complex processes and large space occupation.

b. The removal efficiency for micro-emulsified oil and dissolved oil is limited, making it difficult to meet stringent water quality standards.

c. A large amount of oily sludge is generated, increasing the costs of subsequent treatment and disposal.

d. High operational costs, significant energy consumption, and complex maintenance requirements.

5. New Wastewater Treatment Technology for Offshore Oil Production Platforms

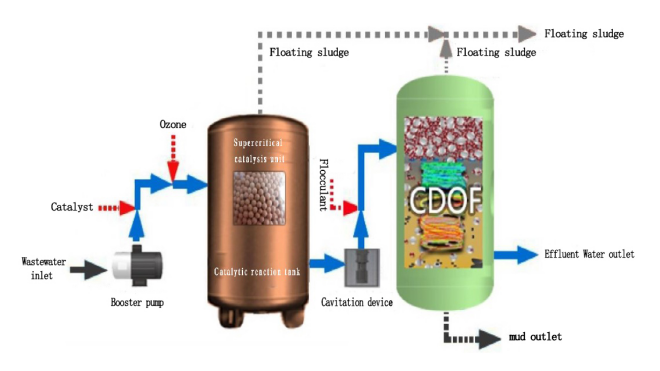

The Cyclonic Dissolved Ozone Flotation Unit (CDOF) developed by Sinokle Technology innovatively combines advanced ozone advanced oxidation technology, cyclone technology, and dissolved air flotation technology, enabling efficient oxidation, decolorization, sterilization, and other functions.

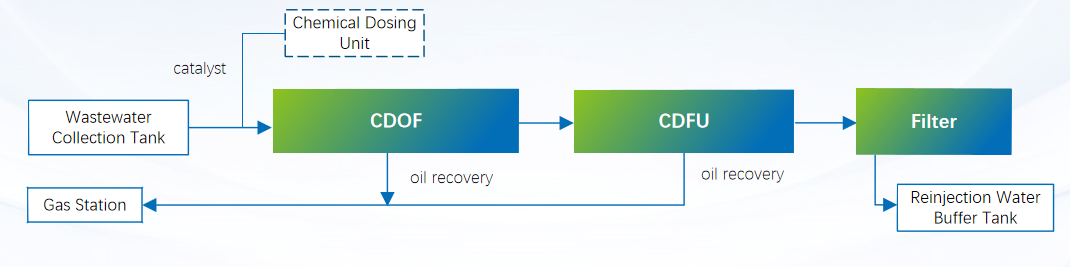

Process Steps:

Inclined plate oil separation pretreatment: Oily wastewater from production separators and electric dehydrators is mixed with chemical agents, then enters the inclined plate oil separator for preliminary separation to remove large free oil particles.

Hydrocyclone secondary separation: The pretreated wastewater enters the hydrocyclone for secondary separation to further remove oil droplets.

CDOF advanced treatment: Wastewater treated by the hydrocyclone enters the CDOF device, where efficient oxidation, decolorization, sterilization, and deep oil-water separation are achieved through ozone catalytic oxidation, cyclone, and dissolved air flotation technologies.

Walnut shell filtration and backwashing: The treated wastewater enters the walnut shell filter for final filtration to ensure the effluent quality meets standards. The medium in the walnut shell filter is regenerated through a backwashing tank, and the backwash water is reused for flushing the inclined plate oil separator, forming a recycling system.

Core Technologies:

Ozone catalytic oxidation technology: Adopting multiple catalytic oxidation technologies to improve ozone utilization efficiency and oxidation effectiveness.

Integration of cyclone and dissolved air flotation: Enhancing flotation efficiency, reducing the dosage of flocculants, and lowering the production of oily sludge.

Fully automated and pressurized-sealed operation: Reducing manual operations and improving operational stability and safety.

Advantages

High treatment efficiency: Fast reaction rate and short treatment time, only 5-10 minutes.

Small footprint: Compact equipment, suitable for the limited space of offshore platforms.

Low operational cost: Low ozone consumption and energy consumption, saving costs.

Excellent treatment effect: Stable effluent quality, meeting stringent water quality standards.

Safety and environmental friendliness: Fully automated closed pressurized operation reduces manual operations and lowers environmental risks.