Electro-Desalting Wastewater Treatment for Refineries: CDFU

Electro-desalting wastewater generally refers to saline, oily, and other pollutant-containing wastewater generated during petroleum refining or chemical production processes after crude oil or industrial wastewater is treated via the electro-desalting process. This type of wastewater is characterized by high salinity, high oil content, high suspended solids, and potential presence of heavy metals, organic substances, etc., making it relatively difficult to treat.

1. Overview of the Electro-desalting Process

Application Field: Primarily used in oil refineries. It separates salts, water, and impurities from crude oil through the action of an electric field to prevent corrosion of subsequent equipment and catalyst poisoning.

Wastewater Source: Effluent produced during the electro-desalting process, including separated brine, oil droplets, suspended solids, and residual chemical agents (such as demulsifiers).

2. Main Characteristics of Electro-desalting Wastewater

High Salinity: Contains a large amount of ions such as Cl⁻, Na⁺, Ca²⁺, and Mg²⁺, with a salt concentration ranging from several thousand to tens of thousands of mg/L.

High Oil Content: Contains free oil, emulsified oil, and dissolved oil, requiring demulsification for separation.

Suspended Solids (SS): Including sediment, colloids, etc

.

Organic Substances: May contain toxic substances such as phenols, sulfides, and cyclic compounds.

Other Pollutants: Heavy metals (e.g., Fe, Ni), residual demulsifiers, etc.

3. Difficulties in Electro-desalting Wastewater Treatment

Inhibition of Microbial Activity by Salinity: Traditional biochemical methods have low treatment efficiency for high-salinity wastewater.

Difficulty in Oil-Water Separation: Emulsified oil requires special demulsification treatment.

High Corrosiveness: High chloride ion concentration tends to corrode equipment.

4. Sinokle's Innovative Process

Sinokle's CDFU technology achieves efficient treatment of oil and suspended solids in electro-desalting wastewater to meet discharge standards, and has obvious advantages compared with traditional air flotation treatment technology.

CDFU: Cyclonic Dissolved Gas Flotation Unit is a new generation of green and high-efficiency vertical tank-type air flotation equipment independently developed by our company. Integrating cyclonic centrifugal separation technology, ultra-fine bubble generation technology, and dissolved air flotation technology, the equipment achieves efficient and rapid separation of oil contamination, emulsified oil, suspended solids, and other pollutants in wastewater through the organic combination of multiple technologies.

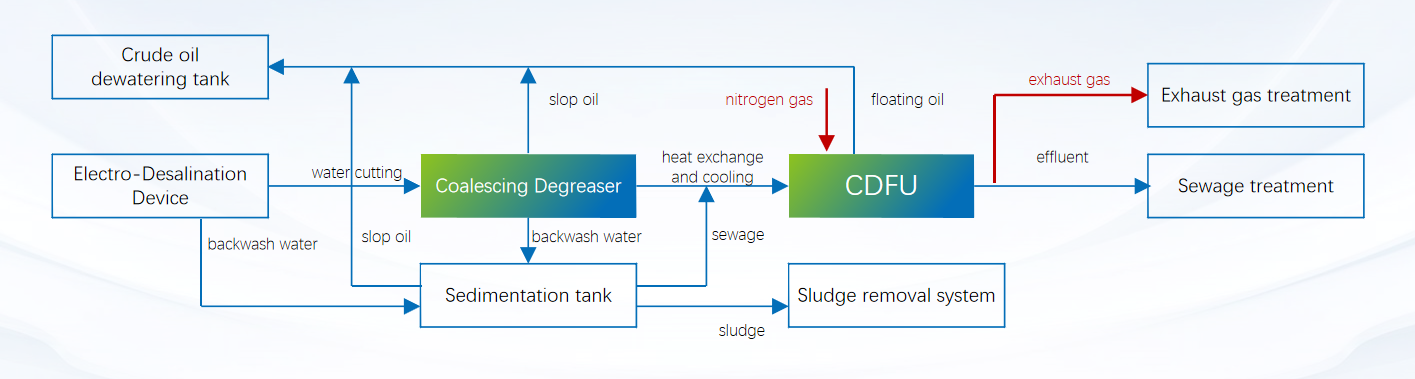

Figure 1. Process Flow of Electro-desalination

Key features of this equipment include:

Oil removal rate > 90% and SS removal rate > 85%;

Demulsification via pure physical means;

Skid-mounted, automated, and informatized design, with remote expert service available;

Pressurized-sealed operation, ensuring safety and environmental friendliness.