The Application of KFM Filter in Power Plant Wastewater Treatment

Introduction

KFM Activated Media Filter has demonstrated an extraordinary technical advantages in power plant wastewater treatment, especially in oily wastewater treatment. This technology utilizes atomic layer deposition to modify activated media, achieving efficient purification through a triple mechanism of super-hydrophilic nanostructures, negative charge adsorption, and physical interception.

KFM Activated Media Filter

Core Technical Features

Ultra-High Filtration Precision: Minimum filtration accuracy reaches 1㎛, with over 95% interception efficiency for 1㎛ suspended solids. The oil content of effluent can be reduced to <5 mg/L, and suspended solids (SS) to ≤2 mg/L.

Long Lifespan: The filter media exhibits strong wear resistance, with a normal lifespan of up to 15 years. Annual replenishment rate is only 5%, and wear rate is as low as 0.07%.

Intelligent Operation Control: A fully automated PLC control system enables intelligent backwashing. Filtration performance is fully restored within 5–10 minutes of backwashing, while backwash water consumption is reduced by 70%.

Case Study

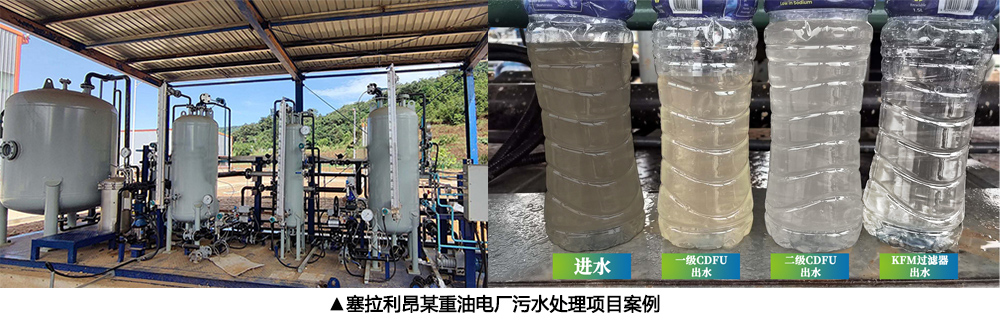

In a heavy oil power plant wastewater treatment project in Sierra Leone, a combined process of two-stage CDFU + KFM filters was adopted, with a treatment capacity of 120 m³/d. The oil content of influent was <2000 mg/L, and after treatment, the oil content of effluent stabilized at <5 mg/L, with a significant reduction in suspended solids. The system features a skid-mounted design with a compact footprint, making it particularly suitable for space-constrained scenarios in power plants.

Wastewater Treatment Effect Comparison: From left to right - influent, 1st-stage CDFU effluent, 2nd-stage effluent, KFM effluent.

Project in Sierra Leone

Technical Comparison

Compared with traditional media filter, KFM activated media filter demonstrates significant advantages: its negatively charged surface provides self-sterilizing capability, effectively preventing media hardening. The backwash intensity required is only 12–15 L/(s·m²), lower than that of anthracite and silicon carbide media. The filtration accuracy meets the SY5329 Grade II standard, far exceeding the Grade III requirement of conventional filter media.

The KFM filter, through its modular design and intelligent control system, delivers an efficient and stable solution for oily wastewater in power plants. Its exceptional treatment performance and low operational costs make it the preferred technology in the field of power plant wastewater treatment.