Know More about Fracturing Flowback Fluid

What is Fracturing Flowback Fluid?

Fracturing flowback fluid is a special type of wastewater generated after hydraulic fracturing operations in oil and gas fields. Hydraulic fracturing is a commonly used stimulation technique in oil and gas field development, where high-pressure fluid is injected into the formation to create fractures. The high-pressure fluid mixes with formation fluids and returns to the surface, forming the fracturing flowback fluid. The primary components of this operational wastewater include guar gum, corrosion inhibitors, gel breaker, petroleum hydrocarbons, and various other chemical additives.

What are the characteristics of fracturing flowback fluid?

Fracturing flowback fluid is characterized by "three highs": high COD value, high stability, and high viscosity.

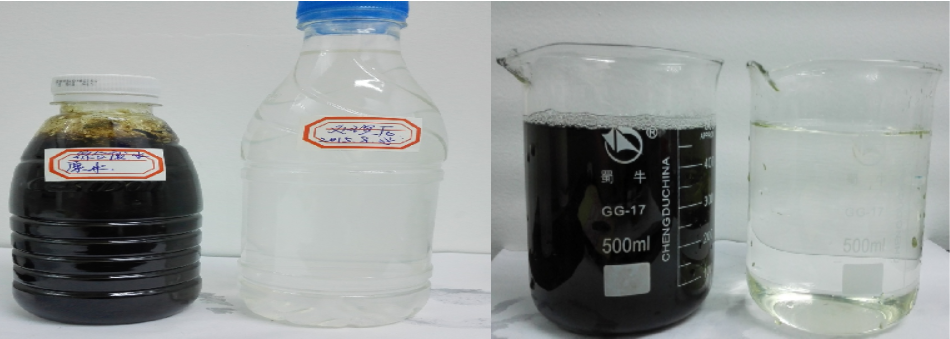

Sample of Fracturing Flowback Fluid

What are the difficulties in treating fracturing flowback fluid?

1. Complex components with numerous types of pollutants at high concentrations, including oils, suspended solids (SS), guar gum, and various chemical additives.

2. High viscosity and severe emulsification make separation challenging.

3. Significant fluctuations in water quality and volume, demanding high impact resistance and stability from treatment equipment.

4. Often generated at remote operational sites with limited public infrastructure, requiring treatment systems to be highly automated, compact, and mobile.

What are the traditional processes for treating fracturing flowback fluid?

Traditional processes for treating fracturing flowback fluid typically include steps such as physical sedimentation, chemical flocculation, and biochemical treatment. However, these methods often suffer from issues such as long treatment times, large footprint requirements, significant sludge production, and low automation levels, making it difficult to meet the demands of modern oil and gas field development.

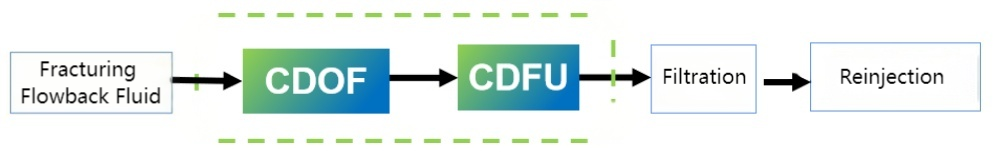

What is Sinokle's innovative process for treating fracturing flowback fluid?

To address the challenges in treating fracturing flowback fluid, Sinokle has developed a new treatment process. This process primarily includes the following steps:

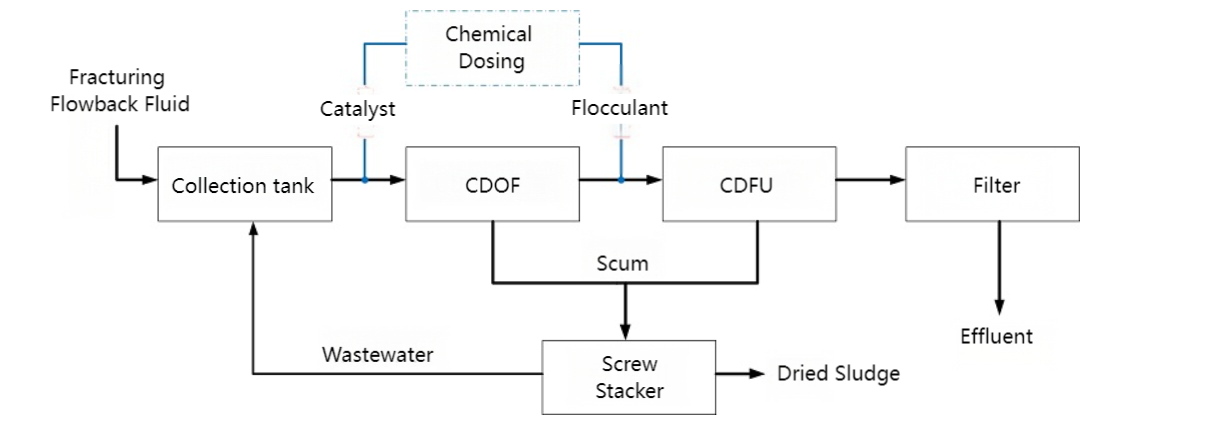

1. Collection and Gravity Sedimentation: The fracturing flowback fluid is collected into surface collection pits/tanks, where large SS are removed through gravity sedimentation.

2. Advanced Oxidation for Viscosity Reduction: The CDOF system utilizes advanced oxidation to reduce viscosity, with catalysts added to enhance oxidation efficiency.

3. Flotation Treatment: After gel breaking, the flowback fluid, mixed with specialized flocculants, enters the CDFU system for flotation to remove SS and oil contents.

4. Sludge Dewatering and Reuse: Sludge from the CDOF and CDFU systems is dewatered using a screw press. The separated water is returned to the collection pits/tanks for reprocessing, while the filter effluent from the CDFU system meets the requirements for reuse in fluid recombination.

What are the advantages of Sinokle's New Process?

1. Short process flow, skid-mounted equipment that can be vehicle-mounted and deployed at well sites, offering high adaptability.

2. The CDOF system, a patented product, enables rapid and thorough oxidation, quickly breaking gels and reducing viscosity to enhance treatment efficiency.

3. Effectively removes calcium, magnesium, and boron ions, reducing sludge production and lowering treatment costs.

4. Short retention time (only 1/5 of traditional methods) and small footprint (only 1/3 of traditional systems), saving land resources.

5. Enclosed operation ensures safety and environmental protection, with full automation capability, reducing labor costs.

Application Case of Sinokle's New Process

Sinokle’s innovative process has been successfully implemented in multiple fracturing flowback fluid treatment projects across various oil and gas oilfields. Practical applications have demonstrated its efficiency in treating flowback fluid, reducing the environmental impact of wastewater discharge, and enabling the recycling of resources through treated water. A notable case involves a large-scale oil and gas field project, where the adoption of Sinokle's technology significantly improved wastewater treatment efficiency and substantially reduced operational costs, providing robust support for the sustainable development of the oilfield.

Treatment Effect Influent vs. Effluent