Coal Washing Wastewater Treatment Process for Coal-Fired Power Plants

1. Sources and Pollution Characteristics of Coal Washing Wastewater

In the continuous production process of coal-fired power plants, the purification of coal washing wastewater is a critical environmental protection task. During the coal pretreatment, processing and combustion stages, procedures such as washing, screening and dewatering generate large volumes of coal washing wastewater. This type of wastewater contains suspended particles (e.g., coal dust, silt), dissolved organic components (e.g., phenols, aromatic hydrocarbons), oils and greases, heavy metal ions (e.g., lead, cadmium, mercury) as well as other inorganic salt pollutants. Characterized by large discharge volume, complex water composition, high suspended solids concentration and oil content, it poses great challenges to purification treatment.

2. Environmental and Ecological Risks of Pollutants

The pollutants contained in the wastewater not only impair water quality, but also potentially threaten the natural environment and ecological systems. For instance, high-concentration suspended solids are prone to causing pipeline blockages and equipment wear; oily substances are difficult to completely remove, and improper disposal may lead to secondary pollution; heavy metal ions exhibit significant toxicity, endangering the health of biological organisms. Meanwhile, drastic fluctuations in water quality impose stringent requirements on the adaptability of treatment technologies.

3. Limitations of Traditional Treatment Technologies

Traditional coal washing wastewater treatment technologies adopted by coal-fired power plants mostly rely on conventional methods such as sedimentation, filtration, coagulation and dissolved air flotation (DAF). Although these methods can partially remove suspended solids and oils from wastewater, they have obvious limitations. First, the treatment efficiency is limited, and the effluent quality fluctuates significantly, making it difficult to consistently meet discharge standards. Second, large quantities of oil-bearing sludge are generated during the treatment process, which not only entails high disposal costs and occupies a large area, but also requires considerable labor input for operation and maintenance. Furthermore, traditional processes have weak shock load resistance and lack effective response measures in the face of frequent water quality changes.

4. Sinokle's Innovative Process and Core Equipment

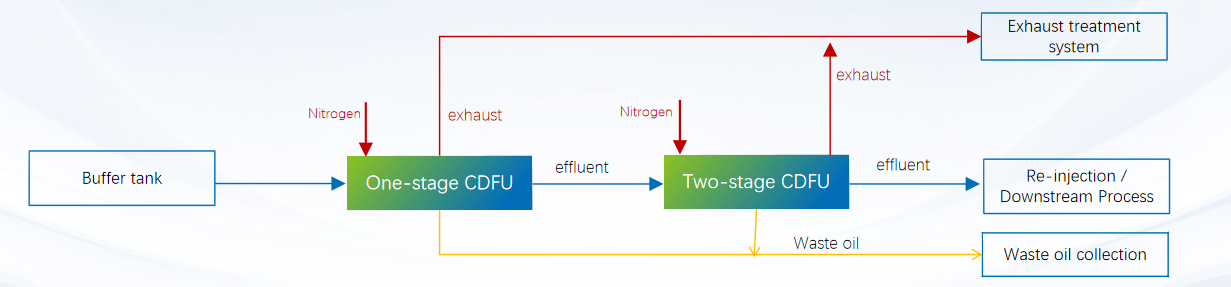

To overcome the limitations of existing technologies, Sinokle has launched an innovative coal washing wastewater treatment process for coal-fired power plants, with its core equipment being the two-stage CDFU cyclonic dissolved air flotation system. Based on purely physical methods and integrated with a number of advanced patented technologies, this process achieves efficient, stable and eco-friendly wastewater purification.

5. Process Operation Flow

The process steps are as follows:

1. Wastewater first enters a collection tank for preliminary filtration to separate large impurities.

2. Then it flows into the two-stage CDFU cyclonic dissolved air flotation equipment for advanced treatment. Inside the CDFU system, a large number of micro-bubbles are formed by injecting high-pressure dissolved air water into the wastewater. Relying on the unique cyclonic structure inside the equipment, these bubbles can fully contact and adhere to pollutants such as suspended particles and oils in the wastewater, lifting them to the liquid surface to achieve pollutant separation.

3. Finally, the treated wastewater enters the subsequent purification unit to further ensure that the water quality meets discharge or reuse standards.

6. Core Technical Performance

This process demonstrates outstanding technical performance: when the influent concentrations of petroleum substances and suspended solids are both ≤ 1000 mg/L, the effluent concentrations of these two indicators can be reduced to ≤ 20 mg/L, achieving remarkable pollutant removal efficiency.

7. Advantages Over Traditional Technologies

Compared with traditional technologies, Sinokle’s new process boasts multiple prominent advantages:

• Strong shock load resistance, capable of adapting to variable water quality and ensuring stable effluent discharge

• High treatment efficiency, as the two-stage CDFU cyclonic dissolved air flotation system enables efficient pollutant separation

• Simplified process flow, dominated by physical methods, which streamlines procedures and lowers operational costs

• Minimal generation of oil-bearing sludge, reducing the burden of subsequent disposal

• No chemical agents required throughout the process, qualifying it as a green technology

• Fully automatic closed-loop operation, small footprint, low demands for manual operation and maintenance, and easy management, which enhances the overall treatment efficiency and operation control level

8. Application Potential and Industry Value

With the above-mentioned significant advantages, Sinokle's new coal washing wastewater treatment process for coal-fired power plants boasts extensive application potential. It provides solid technical support for the environmental protection practices of power plants and helps the industry move towards sustainable operation.