New Breakthrough in Wastewater Treatment: Application of Precious Metal Heterogeneous Catalyst

Against the backdrop of rapid technological evolution, Sinokle leverages its robust R&D foundation and continuous innovation practices to stay at the forefront of the industry. The company has successfully developed and obtained patents for a series of precious metal-doped heterogeneous ozone catalytic materials, which have been large-scale applied in wastewater treatment across multiple sectors including petrochemicals, pharmaceuticals, textile printing and dyeing, and environmental protection. Endowed with high catalytic efficiency, excellent mechanical strength, a large specific surface area, and outstanding acid-alkali resistance, this material series is driving technological innovation in wastewater treatment within related fields.

Heterogeneous ozone catalysts generally exist in solid form. Compared with homogeneous catalytic reaction systems, heterogeneous catalysts can be separated and recovered via simple physical methods, which reduces operational procedures and costs, thereby lowering the overall expense of wastewater treatment. Their active metal components are firmly anchored onto the carrier, which significantly mitigates the corrosion of processing equipment caused by peroxides in traditional homogeneous catalysis processes. Meanwhile, most of these materials possess a rich porous structure that expands the contact interface with reactants, thereby exposing more active sites and effectively accelerating reaction rates.

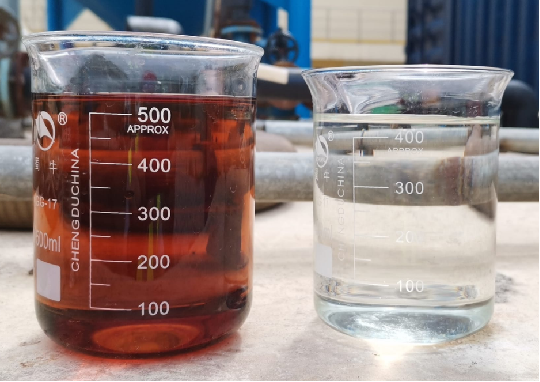

The heterogeneous ozone catalysts of the Sinokle series adopt various transition metal oxides as the core catalytic components, and innovatively dope precious metals such as platinum, palladium, rhodium, silver, ruthenium, cobalt, and nickel uniformly onto the material surface through specific processes and proportions. Based on the characteristics of different types of wastewater, the ratio of each component has been optimized after extensive experiments and engineering validations. The introduction of precious metals can significantly reduce the activation energy of ozone catalytic reactions, accelerate the self-decomposition of ozone in water, increase the generation concentration of hydroxyl radicals (·OH), and then greatly enhance the ozone oxidation efficiency and utilization rate. Verified data shows that its oxidation efficiency is 2–5 times higher than that of single ozone oxidation.

Technical Advantages

●Adopting a combination of multiple transition metal oxides and precious metals as catalytic components, it boasts excellent adaptability to different wastewater types and high catalytic activity.

●Utilizing catalyst loading and staged precision temperature-controlled sintering technology, it ensures high strength of active components while reducing their loss rate, thus guaranteeing stable treatment performance.

●Employing high-activity component materials as catalyst carriers, the special micropore forming technology achieves a large specific surface area, resulting in excellent catalyst loading effect, fast catalytic reaction rate and high efficiency.

●Enabling efficient conversion of ozone into ·OH via catalysis, it improves oxidation efficiency by 2–5 times compared with traditional ozone catalytic oxidation processes.

●Adopting atomic deposition technology for catalyst modification, the catalyst carrier features superhydrophilicity, which prevents the catalyst from contamination, scaling and clogging, enabling long-cycle operation.

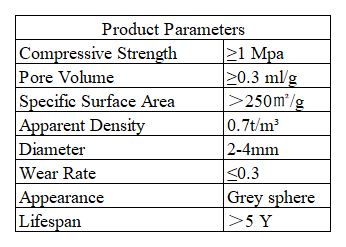

During the catalyst preparation process, special pore-forming and atomic deposition modification technologies are applied to endow the material with superhydrophilicity, thereby enhancing its anti-pollution and anti-clogging capabilities. The multi-stage precision temperature-controlled sintering technology minimizes the loss of components during use and avoids secondary pollution. Meanwhile, the material has an extremely high specific surface area (usually exceeding 300 m²/g), which means it can provide abundant reactive active sites, significantly accelerate the reaction process, and thus achieve higher treatment capacity and better economic benefits in limited space.

Meanwhile, in fields such as chemical engineering and environmental protection, catalysts are often exposed to various complex environments and conditions. This heterogeneous ozone catalyst developed by Sinokle Technology exhibits excellent acid and alkali resistance, and can maintain stable catalytic performance even in strong acid environments. This characteristic enables it to be applied in a broader range of fields, bringing more options and convenience to customers. At present, the heterogeneous ozone catalysts developed by Sinokle have been widely used across multiple industries and sectors. Whether in chemical production, environmental governance or energy development, they have demonstrated outstanding catalytic efficacy and superior performance.

Sinokle boasts a professional R&D and technical support team with profound industry experience and technical accumulation. From the R&D and production of catalytic materials to practical application, the company is capable of providing customers with full-process professional services and comprehensive technical support.