Revolutionizing Tank Farm Dewatering: Sinokle’s Chemical-Free CDFU Solution

Tank Farm Dewatering Status

In refinery tank farms, waste oil can be re-refined. To increase profits and avoid abnormal fluctuations in refining units, it is necessary to dehydrate the tank waste oil, reducing its water content. Tank dehydration methods include both automatic and manual processes. Manual dehydration struggles with accurately adjusting valve openings, leading to oil carryover during the process. Automatic dehydration controls drainage based on the oil-water interface but requires a clear separation for effective oil and water discharge. Waste oil and water mix closely within tanks and often contain severe emulsions, resulting in unclear oil-water interfaces and high oil content in the discharged water. Moreover, waste oil tanks also contain volatile organic compounds, heavy metals, and other harmful substances that are toxic, corrosive, and polluting. If untreated, these substances could severely impact downstream wastewater treatment plants, affecting biochemical treatment efficiency.

Introduction to Treatment Technologies

Current oil removal technologies mainly employ gravity-based and flotation-based treatment processes.

Traditional gravity-based treatment processes involve large tank sedimentation, relying primarily on the density difference between oil and water to achieve natural settling. This method is ineffective for situations where the incoming water has a high oil ratio and severe emulsification. Due to severe emulsification of waste oil, longer settling times are required, necessitating larger tank areas, higher energy consumption (heat tracing), land, and construction costs; low automation levels, difficulties in oil collection, and the need for periodic manual tank cleaning pose safety and environmental risks.

Oil interceptors combined with flotation pools are commonly used in the petroleum industry. However, they require large pool areas, and the micro-bubbles produced by flotation pools have larger diameters, reducing their ability to capture smaller oil particles, thus performing poorly in treating wastewater with high emulsified oil content.

Sinokle's New Tank Farm Dewatering Process:

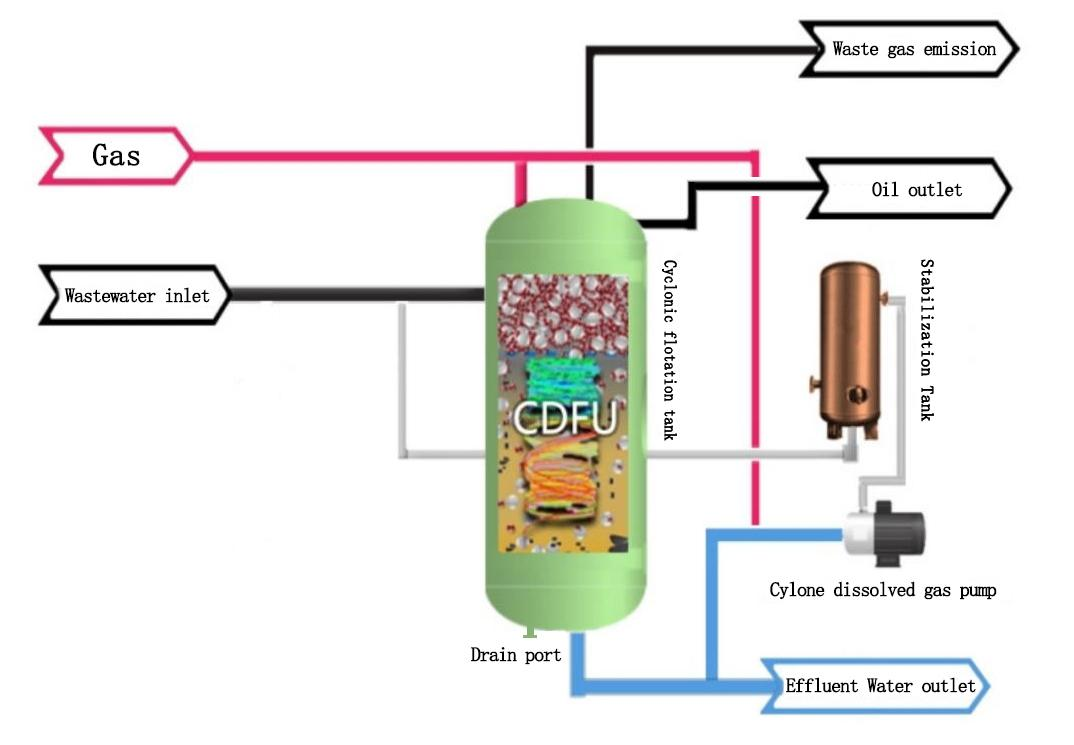

For tank farm dewatering treatment, Sinokle employs an oil-water separation skid-mounted unit centered around "high-efficiency coalescing pressure oil remover + Cyclonic Dissolved Gas Flotation Unit (CDFU)" to treat oily wastewater. The design principle combines collision coalescence, wetting coalescence, cyclonic action, and micro-nano bubble flotation into a new process. The oil remover uses efficient coalescing inclined plate packing to aggregate small dispersed oil droplets into larger ones, significantly shortening the oil droplet retention time for rapid oil-water separation.

CDFU integrates cyclonic centrifugal separation technology, ultra-micro bubble generation technology, and dissolved gas flotation technology. Through the organic combination of multiple technologies, it achieves efficient and rapid separation of waste oil, emulsified oil, suspended solids, etc., from sewage without adding any chemical agents, meeting process indicators through purely physical means.

•Skid-mounted equipment with short retention time and small footprint;

•No addition of chemical agents, capable of removing waste oil above 5um;

•Good quality recovered oil, generating economic benefits after dehydration and re-refining;

•Fully automatic closed pressurized operation, no risk of VOC, H2S leakage, ensuring safety and environmental protection;

•Minimal sludge production, no secondary hazardous waste generation, saving costs.