Beyond Sieving: How KFM Activated Media Filter Redefines Oilfield Wastewater Filtration

In the field of oilfield wastewater treatment, filtration technology, as a vital component of physical treatment methods, is typically employed as a secondary or advanced treatment process to remove contaminants such as colloidal substances, suspended solids (SS), and microorganisms remaining in the water after coagulation and sedimentation. This technology achieves efficient separation of dispersed oil and emulsified oil by virtue of multiple action mechanisms of granular media—including inertial impaction, gravitational sedimentation, hydrodynamic effects, physical interception, and intermolecular forces.

As oilfield water injection development enters the medium-to-high water-contain stage, polymer flooding technology has been applied on a large scale to effectively control water contain and improve crude oil recovery efficiency. When oil wells start producing water, unconsumed polymers are discharged together with the produced fluid, forming polymer-containing wastewater with special properties. At present, the widespread implementation of polymer flooding technology has led to a continuous growth in the output of such polymer-containing wastewater. Compared with conventional oilfield wastewater, the polymer-containing wastewater system is more complex, characterized by significantly increased viscosity, a higher proportion of emulsified oil, enhanced system electronegativity, refined oil droplet size, and greatly improved stability. These characteristics collectively result in a sharp rise in its treatment difficulty.

Filtration processes play a pivotal role in the treatment of polymer-containing wastewater. However, traditional filtration equipment faces numerous challenges in handling such wastewater, including media fouling, unsatisfactory treatment efficiency, and difficulties in backwashing operations. Emulsified oil and SS are adsorbed and intercepted in the filter bed. With the accumulation of contaminants, on the one hand, the head loss of the filter bed increases continuously; on the other hand, the trapped contaminants may be re-released under the action of fluid shear force, causing secondary pollution and seriously affecting the effluent quality. Therefore, the technical performance of filtration media has become a core factor determining the final treatment effect and is of decisive significance for improving effluent quality.

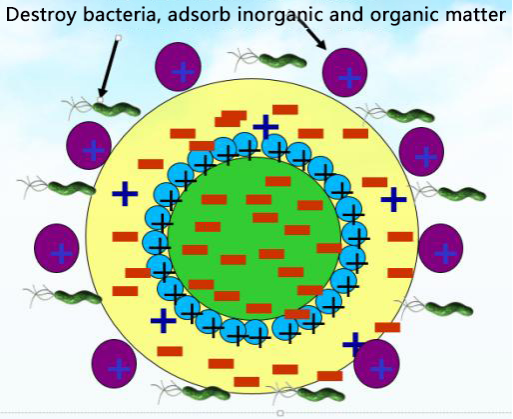

Faced with the double pressures of technical bottlenecks in polymer-containing wastewater treatment and the shortage of clean water resources, Sinokle has successfully developed the KFM Activated Media Filter Filtration System. This new type of activated media filter is based on silicate materials, undergoes 60 preparation procedures and super-hydrophilic modification treatment, and features a high melting point of 1200℃, a density of approximately 1.25, odorlessness, and insolubility in water. The surface of the filter media carries permanent charges, enabling it to effectively adsorb contaminants and exert a bacteriostatic function. It exhibits prominent advantages such as high filtration precision, low fluid resistance, stable effluent quality, strong pollution resistance, easy regeneration and cleaning, and a long service life.

Compared with traditional filter, the KFM achieves a significant improvement in filtration performance and contaminant holding capacity. It effectively reduces the treatment difficulty of polymer-containing wastewater, ensures the treatment process is efficient, environmentally friendly and stably up to standard, provides technical support for the sustainable development of oilfields and the improvement of economic benefits, and meets the requirements of the low-carbon and green oilfield development strategy.

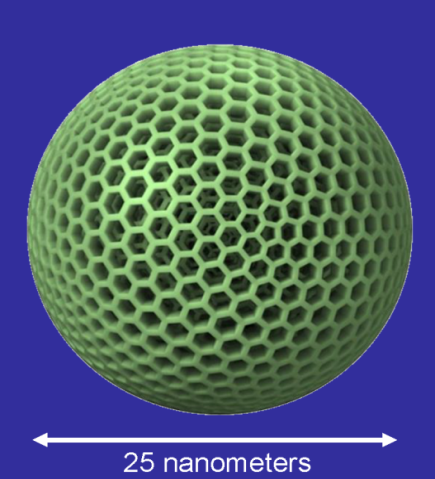

The separation mechanism of the KFM activated filter media filter consists of two key processes: first, the migration of particles in water toward the surface of the filter media, followed by the stable adsorption of particles onto the media surface. Through these two steps, efficient removal of suspended solids and effective control of effluent turbidity are realized. Filtration mainly occurs within the pore structure of the filter media layer. Its suspended particle interception efficiency is positively correlated with the specific surface area of the filter media—generally, the larger the specific surface area, the better the interception efficiency. As SS continuously deposit inside the filter media pores, the resistance of sediments in the pores gradually increases. When the resistance and adhesion force reach equilibrium, the particles become desorbed and migrate deeper into the filter media layer. It is evident that the filtration process is not a simple physical interception and screening effect, but a synergistic effect of multiple physical and chemical mechanisms, accomplished through the two stages of migration and adsorption.

After activation, the surface area of the KFM activated filter media is 300 times that of quartz sand. The schematic diagram of its surface nanostructure is shown in the figure below.

In summary, the KFM Filtration System boasts prominent advantages including strong contaminant adaptability, high purification efficiency, a small footprint, and low construction costs, and can be flexibly adapted to a variety of engineering application scenarios. This system demonstrates excellent performance in terms of effluent quality, designed filtration rate, filtration cycle and backwashing effect, effectively overcoming the technical drawbacks of traditional filters and filter media.