Revolutionizing Produced Water Treatment with CDFU Technology in Mature Oilfields

Challenges in Produced Water Treatment in Mature Oilfields

Currently, many domestic oilfields have entered the middle to late stages of exploitation, characterized by high water content during extraction. To maintain steady crude oil production and accelerate the development of new oil reservoirs, Enhanced Oil Recovery (EOR) technologies—such as polymer flooding and ternary composite flooding—have been vigorously promoted and widely applied in major oilfields like Daqing, Shengli, Yumen, and Dagang.

The widespread adoption of these EOR techniques has significantly increased polymer concentrations in produced fluids, leading to higher viscosity and more stable emulsified oil conditions. As a result, traditional treatment processes struggle to ensure that purified water meets reinjection standards, making produced water treatment a critical bottleneck in surface facility development.

Innovative CDFU Technology for Efficient Oil-Water Separation

Focusing on a produced water purification project at a Daqing oilfield, Sinokle conducted an in-depth analysis of the produced water characteristics and innovatively deployed its latest CDFU (Cyclonic Dissolved Gas Flotation) technology. This solution successfully achieved highly efficient separation of oil, water, and suspended solids (SS) from the oily wastewater stream.

Key Advantages of the CDFU System

The CDFU technology offers the following outstanding benefits:

●CDFU treatment uses purely physical methods to remove floating oil and scum from wastewater, featuring demulsification effects with high efficiency and stability in oil-water separation, unaffected by changes in wastewater or waste oil quality.

●The entire treatment facility is primarily composed of static equipment with a high degree of automation, requiring minimal maintenance, having long inspection periods, and offering good reliability.

●No chemical agents are added, thus no additional scum or sludge is generated, avoiding secondary pollution, and reducing operation and secondary treatment costs.

●The equipment occupies a small area, adopts a skid-mounted design, has a short manufacturing cycle, and enables quick commissioning.

●It features strong shock resistance and stable processing performance. Based on the operational status of our commissioned equipment, the produced water treatment equipment performs well, thoroughly separating oil and water, producing clear effluent without impurities.

●The equipment operates under full pressure in a completely enclosed manner, preventing exhaust gas and odors from escaping, being environmentally friendly.

●With high levels of automation and intelligence, it can achieve IoT remote control, saving labor.

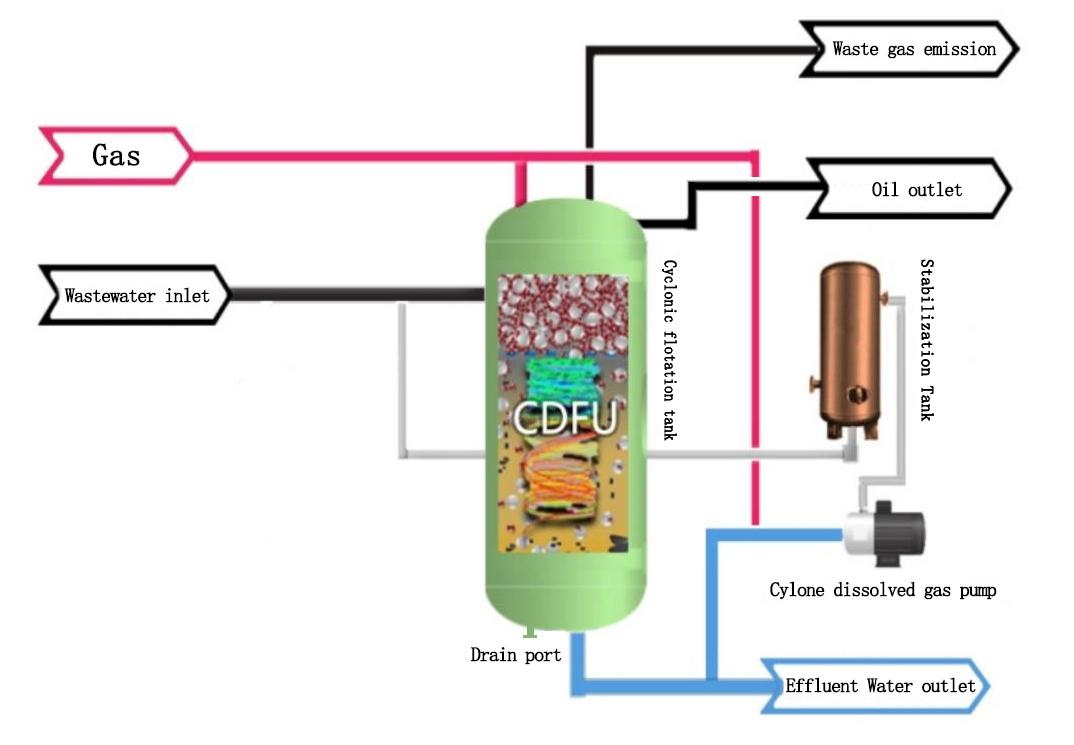

Process Flow of the CDFU System

Produced water is pumped into the CDFU unit, where intense cyclonic motion brings floating oil, dispersed oil, emulsified oil, and SS into rapid contact with micro-nano bubbles generated by the dissolved air system.

The physical properties of these micro-nano bubbles—particularly surface tension—rupture emulsified oil films through purely mechanical means, achieving effective demulsification. Simultaneously, oil-coated suspended particles are captured by the rising bubbles.

This multi-phase mixture (oil, solids, and bubbles) aggregates in the CDFU core zone and floats to the top of the vessel, entering an integrated oil collection chamber. Waste oil is then discharged automatically via the outlet under system pressure.

Treated water meeting discharge standards is transferred by an outlet pump to downstream processes. Separated waste oil flows by static pressure into a dedicated storage tank. Exhaust gases from the CDFU are routed to a specialized off-gas treatment system.

All operations—including effluent discharge, oil removal, sludge handling, venting, and air replenishment—are fully automated. Dissolved air inflow and stabilization tank venting are also automatically regulated.

Project Performance and Economic Benefits

The system is designed for a treatment capacity of 180 m³/h. Influent specifications include:

Oil content ≤ 150 mg/L

Suspended solids ≤ 300 mg/L

After single-stage CDFU treatment, both oil and suspended solids are reduced to < 20 mg/L, fully satisfying the client's design requirements.

The entire system occupies less than 30 m², requires no chemical additives, and consumes only minimal electricity and nitrogen. The calculated operating cost is as low as ¥0.2 per ton of treated water, demonstrating exceptional economic competitiveness alongside significant environmental benefits.