Sinokle’s CDFU Technology: Revolutionizing High-Efficiency Acidic Water Treatment for Industrial Applications

In industrial production processes, the treatment of acidic water has long been a critical issue in the environmental protection field. Such water typically contains high concentrations of pollutants such as sulfides, ammonia nitrogen, and phenols, with a low pH value, making it challenging to treat. Sinokle Technology, leveraging its innovative wastewater treatment technologies, provides efficient and reliable solutions for acidic water management.

Characteristics and Treatment Difficulties of Acidic Water

Acidic water is mainly derived from industrial processes such as oil refining, chemical engineering, and coking. Its typical characteristics include high oil content (up to 500-3000mg/L), high suspended solids content (e.g., coke powder: 50-200mg/L), and complex and variable pollutant compositions. A large proportion of oil droplets in such water are small (<5μm) with severe emulsification, which traditional treatment methods often struggle to separate effectively.

Multiple Challenges in Acidic Water Treatment:

High-concentration pollutants can affect subsequent treatment efficiency (e.g., easy clogging of strippers, leading to unplanned production shutdowns).

Substances such as sulfides and ammonia nitrogen produce irritating odors, endangering the environment and employee health.

Direct discharge imposes significant environmental compliance pressures on enterprises.

Sinokle's Technologically Innovative Solutions

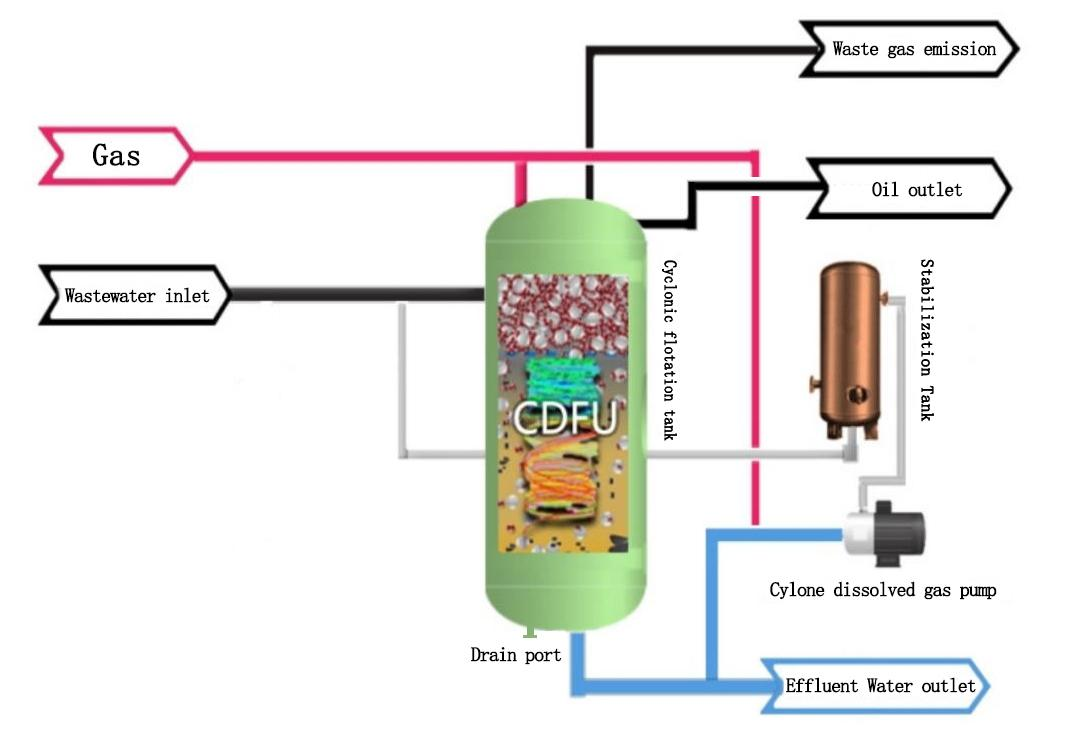

Cyclonic Dissolved Gas Flotation Unit (CDFU) Technology

Sinokle's core CDFU technology integrates cyclonic separation, dissolved gas flotation, and ultra-fine bubble technology, enabling efficient removal of oil and suspended solids from acidic water. The bubbles generated by this technology have a diameter of only 5-30 microns, greatly improving oil-water separation efficiency with a single-stage oil removal rate exceeding 90%.

Multi-Stage Combined Processes

Tailored to different water quality characteristics, Sinokle offers various process combinations:

lHigh-concentration conditions: Coalescing Pressure Oil Separator + Multiphase Cyclonic Filter + KHC Coalescing Oil-water Separator

lConventional conditions: Multiphase Cyclonic Filter + KHC Coalescing Oil-water Separator

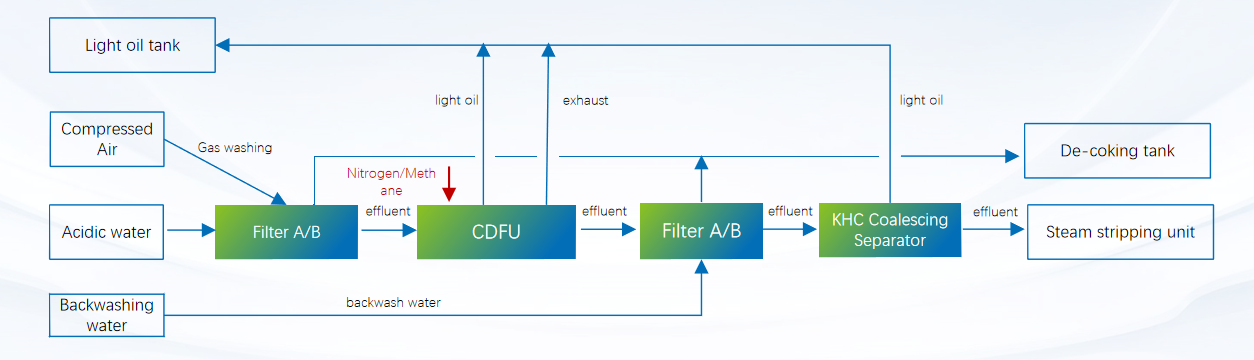

lComplex conditions: Coarse Filter + CDFU + Fine Filter + KHC High-Efficiency Coalescing Oil-water Separator

Technical Advantages and Innovative Features

High-Efficiency Treatment PerformanceSinokle's technologies can reduce inlet oil content from ≤5000mg/L to ≤50mg/L, with significant suspended solids removal effects. In an oil refinery project in Chad, Africa, with a treatment capacity of 20m³/h and an inlet oil content of ≤500ppm, the effluent oil content is reduced to ≤15ppm (excluding dissolved oil).

Intelligent Operation and ControlEquipped with a fully automatic PLC control system, the equipment achieves intelligent backwashing and remote monitoring, significantly reducing labor costs. The system has strong shock resistance, adapting to ±30% water volume fluctuations to ensure stable operation under complex conditions.

Economic and Environmental BenefitsCompared with traditional gravity sedimentation processes, Sinokle's technologies reduce operating costs by 20-30% and occupy 2/3 less space. For a project with a treatment capacity of 50m³/h, 1,584 tons of light oil can be recovered annually, creating substantial economic benefits for enterprises.

Practical Application CaseA project with a treatment capacity of 15m³/h and an inlet oil content as high as 150,000ppm (15% v/v) adopted the combined process of Coarse Filter + CDFU + Fine Filter + KHC High-Efficiency Coalescing Oil-water Separator. The effluent oil content is stably maintained at ≤50ppm, effectively solving the challenge of high-concentration acidic water treatment.

Technology Development Prospects

Sinokle Technology continues to pursue technological innovation, having obtained over 30 patents to date, including 7 invention patents and 1 PCT international patent. The company's innovative achievements, such as ultra-fine nano-bubble generation technology and special superhydrophilic modification technology for materials, are driving acidic water treatment technologies toward higher efficiency and environmental friendliness.

With increasingly stringent environmental requirements, Sinokle's acidic water treatment solutions, backed by innovative technologies and stable performance, provide strong technical support for industrial enterprises to achieve environmental compliance and sustainable development. Its successful practices not only address the current technical challenges in the industry but also set a new benchmark for industrial wastewater treatment.