Revolutionizing Oily Wastewater Treatment: Sinokle’s High-Efficiency Coalescing Pressure Oil Separator

In the process of industrial production, the treatment of oily wastewater has always been a significant challenge in the environmental protection field. This type of wastewater is characterized by uneven oil-water mixing, small droplet size, high emulsification degree, and complex composition, which traditional treatment methods often struggle with due to low removal efficiency, high treatment costs, and operational complexity. Sinokle Technology has addressed these industry pain points by developing an efficient Coalescing pressure oil separator, providing a brand new solution for the treatment of oily wastewater through technological innovation.

Technical Principles and Innovative Design

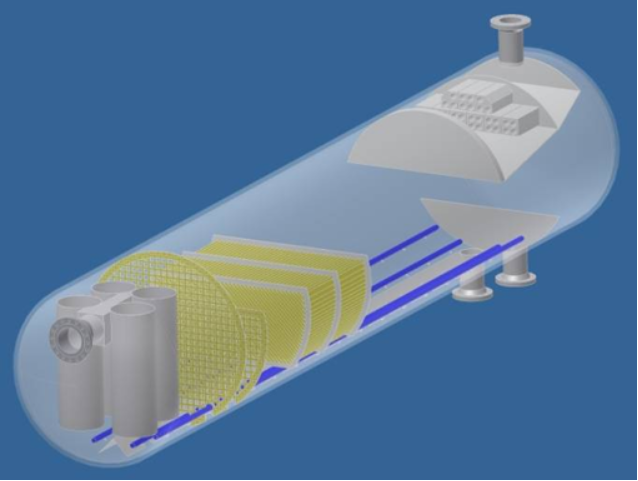

Sinokle's Coalescing pressure oil separator utilizes the principles of coarse-graining and shallow pool theory technology, optimized with CFD flow field. It integrates cyclone pre-separation, efficient coalescing packing, and an automatic sand flushing system into a complete treatment system. The interior of the equipment consists of an inlet pre-separation zone, primary separation zone, and main separation zone, achieving preliminary oil droplet separation through specially designed cyclone separation devices, followed by deep treatment using coalescing packing of various specifications.

Figure 1. Internal Structure of the Separator

The innovation of this equipment lies in its full-flow-field CFD optimized design, which stabilizes internal flow conditions rapidly, maintains laminar flow, and avoids short-circuit flow and circulating flow through computer simulation optimization of the internal flow field of the separator.

Figure 2. Incline Plate Internal Figure 3. Coalescing Filler

Patented coalescing packing features a special fluid structure design, large specific surface area, and high separation efficiency. By utilizing localized effects of micro-fluids to increase collision contact probability, it accelerates the coalescence of dispersed oil droplets, reducing separation time.

Outstanding Technical Performance Indicators

Sinokle's Coalescing pressure oil separator excels in technical parameters, with single-stage oil removal efficiency exceeding 90%, capable of handling oil droplets as small as <30um in diameter. Compared to traditional equipment, it reduces land occupation by 30% and energy consumption by 40%.

The equipment operates in a fully enclosed, pressurized, and automated mode, equipped with an automatic monitoring system based on PLC for precise level control and automatic backwashing. The specially designed sand flushing and sludge discharge device effectively prevents packing blockage, ensuring long-term stable operation of the equipment, with a service life of over 15 years.

Extensive Industry Application Cases

In the petrochemical industry, Sinokle's Coalescing pressure oil separator has been successfully applied in multiple large-scale projects. The circulating water oil removal treatment project at an Uzbekistan refinery adopted two units with a total treatment capacity of up to 17,000 m³/d, demonstrating the equipment's capability for large-scale processing.

Figure 4. On-site Equipment

For treating high-oil-content wastewater, the equipment also performs excellently. In a certain petrochemical electro-desalting wastewater treatment project, where the influent oil content was as high as 10%-20%, the effluent quality after treatment met strict emission standards.

Technical Comparison with Traditional Processes

Compared to traditional oil removal technologies, Sinokle's Coalescing pressure oil separator exhibits clear advantages in several aspects. Traditional gravity separation relies on the density difference between oil and water for separation, resulting in low processing efficiency and large land occupation; coarse-graining does not require chemical agents but demands lower inlet concentrations; filtration, although simple in equipment, requires frequent backwashing.

Figure 5. Process Diagram of the Oil Droplet Separation after Coalescence

Sinokle's technology combines the benefits of various processes, maintaining the non-chemical addition characteristic of physical methods while significantly enhancing separation efficiency through coalescing technology. Its compact design is particularly suitable for plants with tight land availability, and automated operation markedly reduces manual operation costs.