Breaking Through the Bottleneck of Polymer-Containing Wastewater Treatment: Innovative Application of the KFM Activated Media Filter

Introduction: The Role of Filtration in Oilfield Wastewater Treatment

In the field of oilfield wastewater treatment, filtration technology serves as a key component of physical treatment methods. It is typically employed as a secondary or advanced treatment step to remove residual pollutants—such as colloidal substances, suspended solids, and microorganisms—following coagulation and sedimentation. This technology relies on multiple particulate media mechanisms, including inertial impaction, gravity settling, hydrodynamic effects, physical retention, and intermolecular forces, to achieve efficient separation of dispersed and emulsified oils.

Challenges of Polymer-Containing Wastewater

As oilfield water injection development reaches moderate to high water-cut stages, polymer flooding has been widely implemented to control water content and enhance crude oil recovery. When oil wells produce water, incompletely consumed polymers are carried into the production fluids, resulting in polymer-containing wastewater with unique characteristics. The large-scale application of polymer flooding has led to a continuous increase in such wastewater volumes. Compared to conventional oilfield wastewater, polymer-containing systems are more complex: they exhibit significantly higher viscosity, a greater proportion of emulsified oil, enhanced electronegativity, finer oil droplet size, and improved stability. These factors collectively raise the difficulty of treatment considerably.

Limitations of Conventional Filtration Systems

Filtration plays a critical role in treating polymer-containing wastewater, yet traditional filtration equipment faces several operational challenges: rapid filter fouling, suboptimal treatment efficiency, and difficulties in backwashing. Emulsified oils and suspended solids adsorb and accumulate within the filter layer, leading to continuous increases in head loss. Moreover, deposited contaminants may be re-released under fluid shear forces, causing secondary pollution and negatively impacting effluent quality. Consequently, the technical performance of the filtration media becomes a decisive factor in determining treatment outcomes.

Innovation in Filtration: The KFM Activated Media Filter

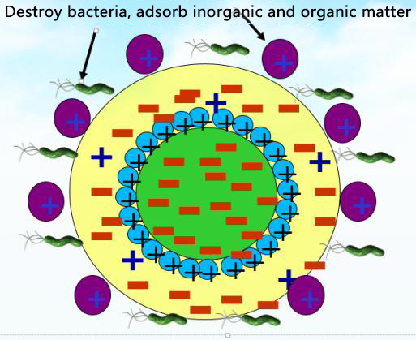

In response to the dual challenges of treating polymer-containing wastewater and the growing scarcity of clean water resources, Sinokle has successfully developed the KFM Activated Media Filter system. This advanced filtration media is based on a silicate matrix and undergoes 60 precision manufacturing steps followed by super-hydrophilic surface modification. It features a high melting point (200°C), a density of approximately 1.25 g/cm³, is odorless and water-insoluble, and carries a permanent surface charge that enables effective contaminant adsorption and antimicrobial functionality. The media demonstrates outstanding advantages, including high filtration accuracy, low hydraulic resistance, stable effluent quality, strong anti-fouling capacity, ease of regeneration, and long service life.

Performance Advantages Over Conventional Media

Compared to conventional filtration media, the KFM system achieves significant improvements in both filtration performance and dirt-holding capacity. It effectively reduces the treatment difficulty of polymer-containing wastewater, ensuring an efficient, environmentally compliant, and stable treatment process. This technology provides essential support for the sustainable and low-carbon development of oilfields while enhancing economic returns.

Separation Mechanism: Migration and Adsorption

The separation process of the KFM Activated Media Filter involves two key stages: first, the migration of suspended particles toward the media surface, followed by their stable adsorption onto the media. Through these sequential steps, the system achieves efficient removal of suspended solids and effective control of effluent turbidity.

Filtration Dynamics and Media Structure

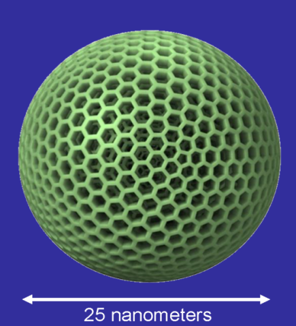

Filtration primarily occurs within the pore structure of the media bed. Particle retention efficiency is positively correlated with the specific surface area of the media—generally, a larger surface area results in higher retention. As particles deposit within the pores, resistance gradually increases. When hydrodynamic drag balances adhesive forces, particle desorption occurs, allowing migration deeper into the filter bed. Thus, filtration is not merely mechanical sieving, but rather a synergistic outcome of multiple physicochemical mechanisms through particle migration and adsorption.

Enhanced Surface Characteristics

After activation, the KFM media exhibits a specific surface area 300 times greater than that of quartz sand. A schematic diagram illustrating its surface nanostructure is provided below.

Conclusion: A Adaptable and Efficient Filtration Solution

In summary, the KFM filtration system offers strong adaptability to various pollutants, high purification efficiency, a compact footprint, and low construction costs, allowing flexible deployment across diverse engineering applications. It demonstrates excellent performance in effluent quality, filtration velocity, filter run length, and backwashing efficiency, effectively overcoming the limitations of conventional filters and media.