Crude Oil Tank Farm Dewatering Treatment: Physical Method For Efficient Oil Removal

A Key Link in Ensuring Oil Quality and Safety

Crude oil tank farm dewatering is a crucial process in the production, storage, transportation, and processing of petroleum. It involves separating water sedimented at the bottom of oil tanks from crude oil to ensure crude purity and prevent equipment failures. This process serves as a fundamental procedure for maintaining production safety and oil product quality.

Four Major Challenges in Crude Oil Tank Farm Dewatering

1. Incomplete Separation: The tight mixture of crude oil and water results in residual moisture and impurities, directly compromising oil product quality.

2. High Costs: Traditional technologies demand significant energy and chemical agents, leading to elevated operational and maintenance expenses.

3. Prominent Safety Hazards: Delayed water separation can disrupt tank pressure and temperature balance, potentially triggering explosions.

4. Severe Environmental Risks: Improper handling of oil-contaminated wastewater containing heavy metals may cause environmental pollution, while sludge disposal remains a considerable challenge.

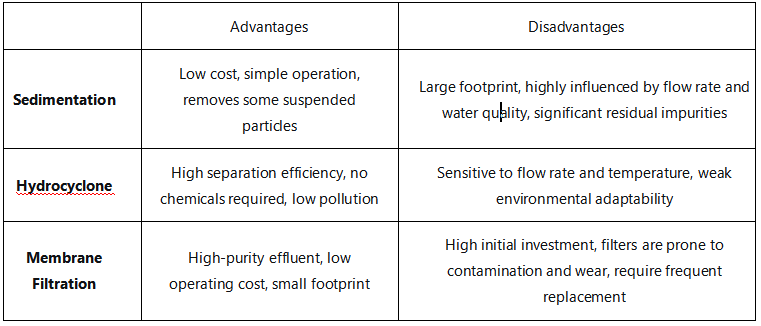

Technical Comparision

Traditional technologies all have evident shortcomings, making it difficult to balance efficiency, safety, environmental protection, and low-cost requirements.

Sinokle's New Tank Dewatering Process for Crude Oil Tanks: A Pure Physical Technology Innovation

Addressing the pain points of traditional technologies, Sinokle Technology has developed a patented new process. Comprising a "Coalescing Oil-Water Separator + CDFU (Cyclonic Dissolved Gas Flotation Unit)", it employs purely physical principles to achieve demulsification, oil removal, and oil-water separation without requiring any chemical additives, tackling the root causes of tank draining challenges.

Crude Oil Tank Farm Project in Sichuan Province

Six Core Advantages of the New Process

1. High Efficiency: Oil removal efficiency exceeds 95%, delivering stable and reliable separation performance.

2. Eco-friendly & Economical: Recovered oil can be directly reused. The process prevents secondary pollution, generates no oily sludge, and offers both environmental and economic benefits.

3. Compact Footprint: Features a streamlined process and skid-mounted equipment design, resulting in a small area requirement.

4. Easy Deployment & Maintenance: Highly automated with a short construction cycle, allows for online implementation, and boasts low operational costs.

5. Strong Adaptability: Exhibits excellent resistance to fluctuations in water quality and maintains outstanding operational stability.

6. Safe & Reliable: Employs a pure physical technology that eliminates chemical risks, systematically avoiding potential safety hazards.