Application of Coalescing Oil-Water Separators in Refinery Circulating Water Treatment

Refinery circulating water is a recycled water resource used in the petroleum refining process for cooling, washing, and other procedures. During oil refining production, such water is prone to contamination from oil leakage, generating oily wastewater. The treatment challenges are primarily reflected in the high degree of oil emulsification, complex composition of pollutants, and significant fluctuations in water quality. Traditional treatment methods often struggle to achieve stable and efficient results.

Applications of Coalescing Oil-Water Separators

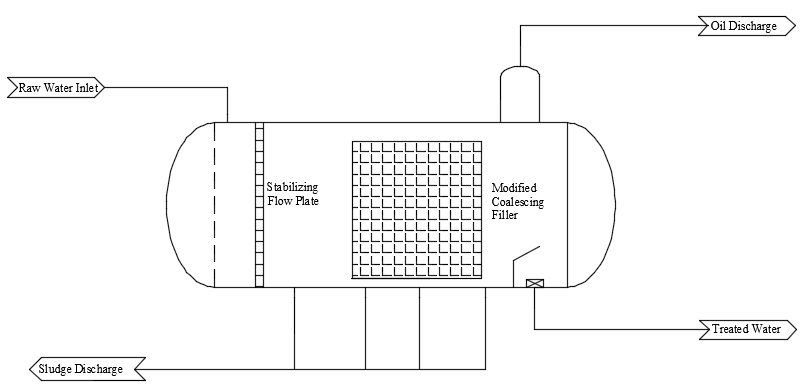

Coalescing oil-water separators utilize specially designed coalescing media and the coarsening principle to achieve oil-water separation. The working principle is as follows: when oily wastewater passes through the special polyester fiber material, tiny oil droplets are captured and adsorbed by the fibers. Driven by the fluid, these droplets move along the fibers to intersection points where they accumulate, coalesce through collisions, and form larger oil droplets, ultimately achieving oil-water separation. This technology incorporates a bidirectional flow design and CFD-optimized flow fields to ensure stable internal flow patterns, avoiding short-circuiting and circular flows.

Coalescing Oil-Water Separator

Technical Features and Advantages

This equipment incorporates high-efficiency coalescing inclined plate internals, which increase oil droplet size and reduce retention time. This enables highly efficient oil-water separation while achieving a more compact structure. The specially designed inlet cyclonic device utilizes centrifugal force to rapidly separate dispersed oil, thereby reducing the load on the downstream coalescing media and preventing clogging of the internals.

The coalescing media employs a super-hydrophilic modification technology, where the material surface is modified at the molecular level using atomic layer deposition. This grants the media characteristics such as high density and excellent shape retention. This design enables the equipment to effectively remove oil droplets with a particle size ≥20 µm, offering strong anti-clogging resistance and high operational stability.

Application Cases

In the circulating water deoiling project at an Uzbek refinery, coalescing oil-water separators were employed with a treatment capacity of 17,000 m³/d, demonstrating exceptional large-scale treatment capability. The equipment operated stably, with effluent quality meeting design requirements, providing reliable technical assurance for the refinery's circulating water system.

The CNOOC Huizhou Refining and Petrochemical project for treating oily water from sludge washing adopted a combined process of "Coalescing Oil-Water Separator + CDFU," with a treatment capacity of 720 m³/d. This project successfully treated high-oil-content wastewater, achieving good effluent results and highlighting the technology's adaptability under complex water quality conditions.

A desalination wastewater treatment project at a petrochemical enterprise in Zhejiang also utilized the combined process of Coalescing Oil-Water Separator + CDFU, with a treatment capacity of 900 m³/d. This further validated the applicability of this technology in the chemical industry.

On-spot Equipment