Advanced Oxidation Processes: Unlocking Efficient Industrial Wastewater Treatment

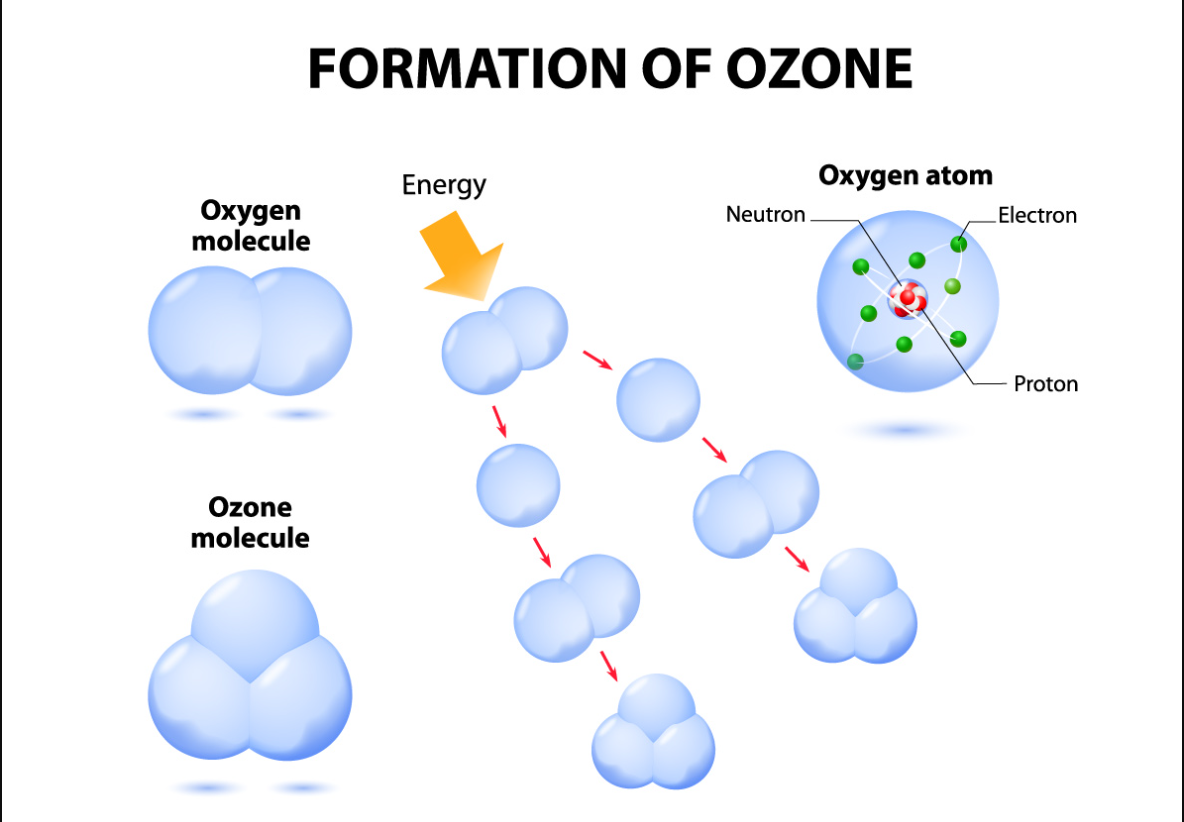

Ozonation

Modern society fundamentally depends on efficient wastewater treatment systems to address environmental challenges. A critical focus is enhancing the biodegradability and mineralization of refractory organic compounds, which involves transforming complex aromatic structures into simpler aliphatic compounds. These are subsequently mineralized into stable end products like carbon dioxide (CO₂) and water (H₂O), or converted into forms amenable to biological degradation. Advanced Oxidation Processes (AOPs) play a pivotal role here, leveraging chemical reactions—either through direct ozone oxidation or indirect hydroxyl radical (·OH) generation—to break down persistent organic pollutants. This makes AOPs particularly effective for industrial wastewater containing biorefractory contaminants, as they can oxidize a wide range of compounds efficiently. The core mechanism involves producing potent oxidizing agents, especially ·OH radicals (oxidation potential of 2.8 V versus NHE), which non-selectively degrade pollutants into harmless byproducts.

Advanced Oxidation Processes (AOPs)

AOPs are categorized into four main types: ozone-assisted, photocatalytic-assisted, Fenton-assisted, and others like electron beam or persulfate activation. Among these, ozonation stands out due to its sludge-free operation and eco-friendly end products (oxygen and water). Since the early 21st century, ozone—a reactive, unstable gas with a distinct odor—has been widely used in water treatment. It is typically generated via corona discharge in dried air or oxygen. Ozone breaks down large organic molecules into smaller intermediates, which enhance microbial biodegradation by penetrating cell walls more easily. Additionally, ozone reactions generate ·OH radicals, which have a higher oxidation potential than molecular ozone, boosting degradation efficiency. Ozonation also aids in sludge solubilization and reduces biomass yield.

However, the ozonation process is accompanied by two primary drawbacks: (i) a decline in oxidation performance, which stems from the slow reaction rate, poor mass transfer efficiency, and the selective reactivity of ozone; (ii) the production of ozone requires significant energy input, consequently raising the operational expenses. Furthermore, the sole application of ozone fails to achieve full mineralization of numerous refractory organic substances. For this reason, extensive research efforts are necessary to explore the combination of ozone with various water treatment technologies. Such integration aims to enhance the overall treatment efficiency and resolve the challenges encountered in its environmental applications.

Figure 1. Formation of Ozone

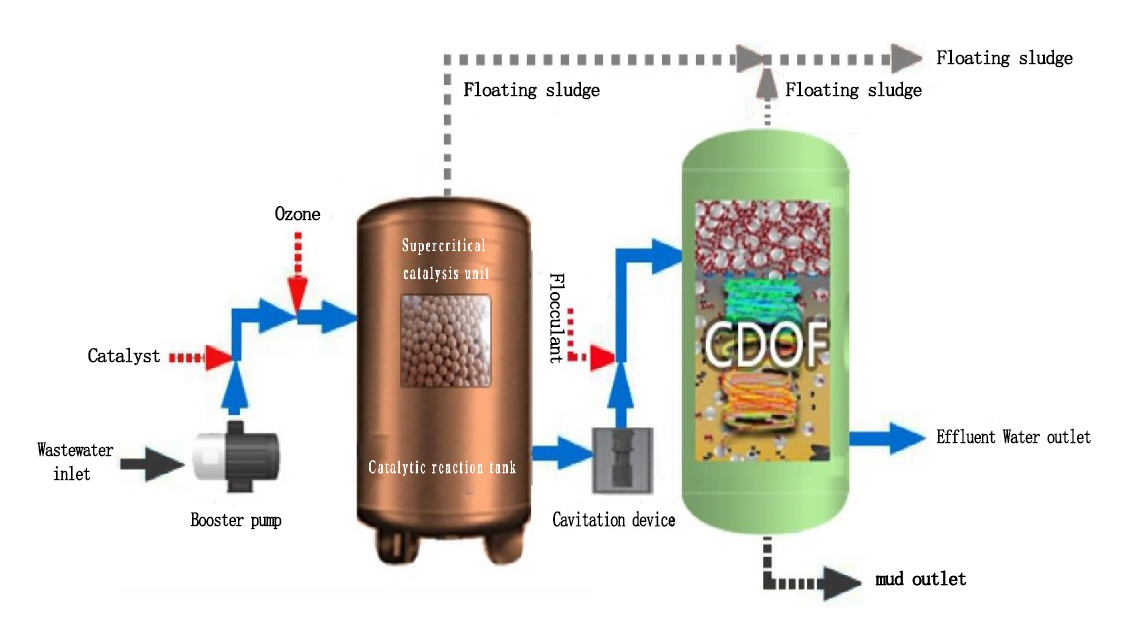

Introduction to CDOF in Wastewater Treatment

CDOF (Cyclonic Dissolved Ozone Flotation unit) is an advanced technology that innovatively combines ozone multi-catalytic oxidation, cyclonic separation, and dissolved air flotation. It efficiently removes contaminants like COD, suspended solids, oils, and pathogens from refractory wastewaters, such as those from oilfields, chemical industries, and municipal systems. Key advantages include ozone utilization rates exceeding 99.98%, reaction times under 15 minutes (significantly faster than traditional methods), a compact footprint (about one-fifth the size of conventional systems), and fully automated, enclosed operation that ensures safety with no ozone leakage. This makes CDOF a sustainable solution for enhancing treatment efficiency while reducing costs and environmental impact .

Figure 2. CDOF Unit from Sinokle

Technical Innovations

- Multi-Catalytic Oxidation: Utilizes both homogeneous and heterogeneous catalysts with supercritical cavitation catalysis, enhancing ozone oxidation efficiency by 2-5 times compared to traditional methods.

- Micro-Nano Bubble Technology: Generates bubbles sized 10-50 μm (microbubbles) and <200 nm (nanobubbles), significantly increasing gas-liquid contact area and residence time while producing hydroxyl radicals during bubble rupture.

- Intelligent Operation: Features fully automated backwashing, catalyst activation/regeneration, and pressure-controlled operation preventing ozone leakage.