New Solution of Crude Oil Tank Dewatering: Coalescence + Cyclonic Gas Flotation

In the storage and production process of crude oil, dewatering in the crude oil tank area is a critical step. Crude oil contains a certain amount of water, which accumulates at the bottom of the tanks and forms a water layer. This water needs to be periodically separated and discharged from the crude oil—a process known as dewatering in the crude oil tank area. However, the wastewater generated after dewatering contains large amounts of petroleum substances, organic compounds, heavy metals, and other impurities. If discharged directly without effective treatment, it can cause severe environmental pollution. Traditional dewatering treatment technologies for crude oil tanks face numerous challenges.

Traditional dewatering technology for the crude oil tank area faces many drawbacks:

1. Difficulty in oil-water separation: The oil and water in crude oil often form relatively stable emulsions, making it difficult to separate them using conventional physical methods.

2. Complex composition of the separated water: In addition to oil-water mixtures, the separated water contains various impurities, including suspended solids (SS), sand, and salts. The composition of the separated water varies significantly depending on the source of the crude oil, increasing the complexity and difficulty of the treatment process.

3. High cost of traditional treatment technologies: Chemical methods require a large amount of chemical agents, while electrical dewatering methods consume a high level of energy. Additionally, some technologies require large equipment and significant space, along with posing substantial safety risks.

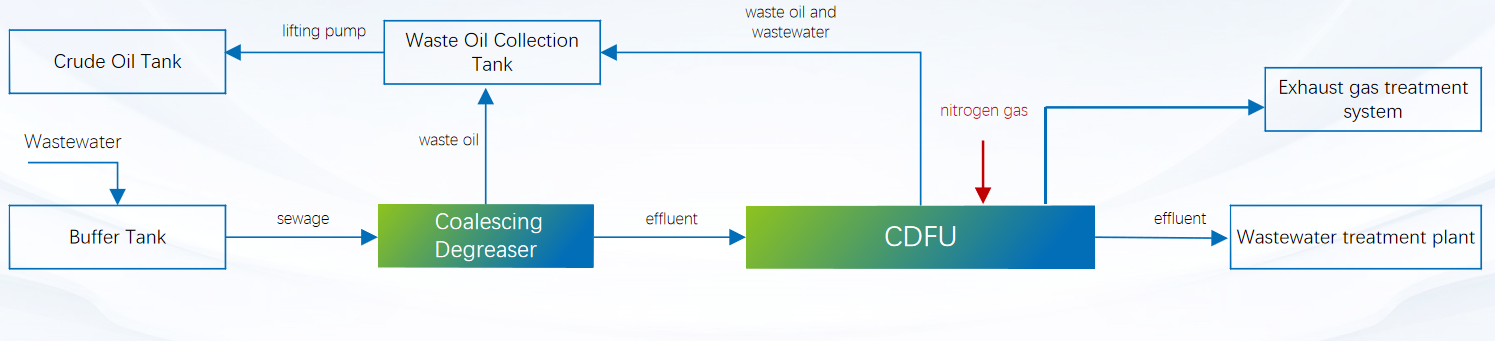

To address these difficulties, Sinokle leverages its patented technologies to develop an effective and innovative treatment process: Coalescing Oil-Water Separator + CDFU (Cyclonic Dissolved Gas Flotation Unit) for industrial treatment.

Coalescing Oil-Water Separator utilizes the coarse-grained principle, shallow pool principle, and CFD simulation tools to optimize the internal space and structure of the tank. Rationally arranging the internal flow field enables oil or SS to rapidly aggregate, coalesce, and either float or sink for separation. Its oil removal efficiency exceeds 90%. The internal packing features a patented structural design with high strength and a long lifespan. Additionally, a specially designed sand flushing and sludge discharge device prevents the filler from being blocked and equipment from being clogged.

Cyclonic Dissolved Gas Flotation Unit (CDFU) integrates cyclonic centrifugal separation technology, ultra-fine bubble generation technology, and dissolved air flotation technology. Air is pumped into a pressurized dissolution tank, where it is forcibly dissolved in water under pressure to form saturated dissolved air water. When the pressure is suddenly reduced, the air dissolved in the water is released, forming a dense mass of micro-bubbles typically ranging from 5 to 30 micrometers in size. These micro-bubbles exhibit high stability and dispersibility.

When wastewater enters the CDFU unit, it mixes with the micro-bubbles released from the dissolved air water. The micro-bubbles rise slowly through the wastewater, colliding with and adhering to oil droplets and suspended solids, forming flocculations with a density lower than that of water. Simultaneously, the wastewater enters the CDFU tangentially along the tank wall, creating a cyclonic flow. The centrifugal force generated by this cyclonic action drives the micro-bubbles and emulsified oil droplets toward the center, further enhancing the removal efficiency of oil droplets and SS.

Under the influence of the cyclonic flow, the bubbles, attached to SS or oil droplets, gradually form a float sludge that rises to the liquid surface. As the bubbles break and release, the pollutants aggregate and coalesce into larger masses. Finally, the accumulated contaminants are periodically removed through a liquid level controller.

On-Spot Wastewater Treatment Unit

The innovative process demonstrates several advantages:

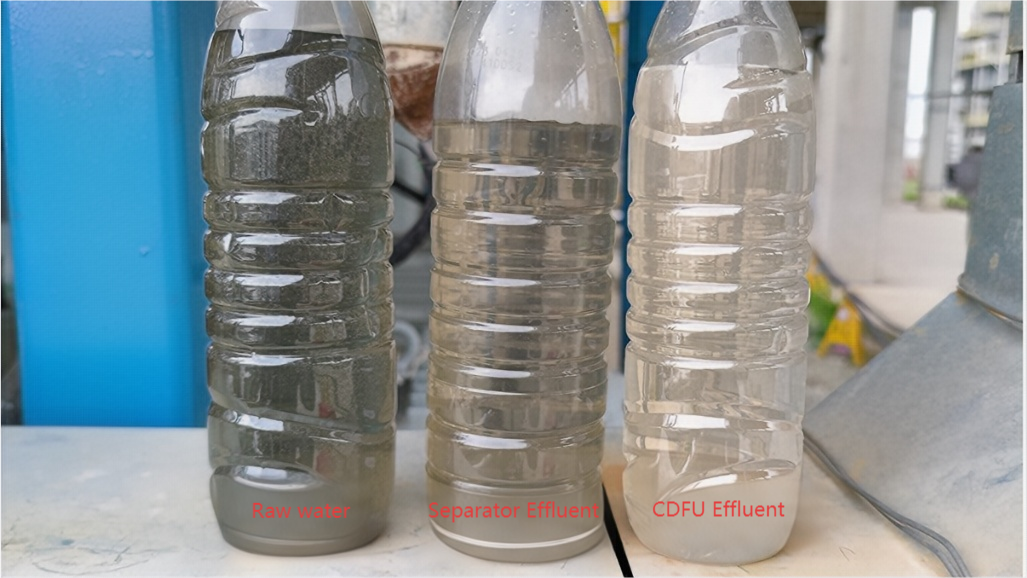

In terms of oil removal efficiency, it achieves exceptional performance through purely physical separation methods, consistently reaching over 95% removal rate, thereby substantially reducing the burden on the following treatment processes.

From an environmental perspective, the entire process does not require chemical additives, achieving demulsification and oil removal through purely physical means. The recovered oil can be directly transported to crude oil tanks for reuse, eliminating secondary pollution and preventing the generation of hazardous oily sludge. This effectively addresses environmental challenges while converting recovered oil into economic benefits.

Regarding operational convenience, the entire process features a compact design with space-saving equipment layout. Utilizing a skid-mounted modular design, it facilitates installation and transportation. The highly automated operation mode simplifies maintenance, with short construction cycles and online implementation capability that doesn't interfere with normal production activities.

From a technical standpoint, the process demonstrates strong adaptability and impact resistance. Even when facing significant fluctuations in water quality. It maintains stable operation, ensuring consistent and reliable treatment performance.

The innovative wastewater treatment process for crude oil tank farms - developed by SINOKLE - integrates Coalescing Oil-Water Separators with CDFU. This solution effectively addresses the key points of traditional methods, demonstrating multiple advantages, including high efficiency, environmental friendliness, operational convenience, and system stability. Showing promising application prospects in the field of crude oil tank farms wastewater treatment, this technology is poised to drive green and sustainable development across the industry.