An Innovative Treatment Process for Alcohol Production Wastewater

The alcohol industry is a crucial fundamental material sector in the national economy. Alcohol is widely used in various fields such as healthcare, pharmaceuticals, chemical engineering, and the chemical engineering. What’s more, it serves as an alcohol base, extraction agent, solvent, detergent, and surfactant. The most significant environmental impact of the alcohol industry is water pollution, as the production process generates a large amount of wastewater. This wastewater primarily comes from distillers’ grains after distilling the “fermented mash”, washing water from production equipment, and cooling water used in processes such as cooking, saccharification, fermentation, and distillation.

Alcohol Production Plant

Alcohol wastewater has the following characteristics:

1. High Content of Suspended Solids (SS): The average SS concentration is as high as 40,000 mg/L.

2. High Temperature: The average temperature reaches 70℃, and the wastewater discharged from the bottom of the distillation pot can be as high as 100℃.

3. High Concentration: The COD of the wastewater can range from 20,000-30,000 mg/L, including SS, soluble COD, and collides. Organic matter constitutes 93%-94%, while inorganic matter makes up to 6%-7%. The organic components are primarily carbohydrates, followed by nitrogen-containing compounds, microorganisms, and by-products such as butanol and ethanol.

4. Acidity: The wastewater contains approximately 500mg/L of organic acids, resulting in an acidic nature. During the initial operational phase, adding alkali or returning sludge can be considered to balance the pH value of wastewater. Once the operation stabilizes, the system develops sufficient buffer capacity, making the addition of alkali or sludge return unnecessary.

5. Inorganic Matter: Inorganic matter primarily originates from dust and impurities in the raw materials.

The biodegradability of wastewater from alcohol production is poor. If the wastewater directly discharged to the downstream wastewater plant, it will severely affect the normal operation of the biochemical system, causing the fluctuation of the effluent. To solve this problem, pre-treatment for improving the biodegradability of the wastewater is necessary, realizing the harmless treatment in the wastewater treatment plants.

Currently, common treatment processes for alcohol production wastewater include anaerobic sludge tank processes, Up-flow Anaerobic Sludge Blanket (UASB) + anoxic tank + contact oxidation processes, A/O processes, and UASB + oxidation pond processes. Although these conventional methods can handle wastewater from typical alcohol plants, they have drawbacks such as a large equipment footprint, unstable treatment efficiency, poor resistance to impact loads, long equipment commissioning cycles, safety risks associated with combustible gas leaks, and complex operation and maintenance that heavily relies on experienced technical personnel.

CDOF Equipment

To solve such challenges in treating alcohol production wastewater, SINOKLE has drawn on production practices and scientific experimentation, integrating its proprietary core patented technology CDOF (Cyclonic Dissolved Ozone Flotation Unit), to launch a treatment process specifically adapted for alcohol production wastewater.

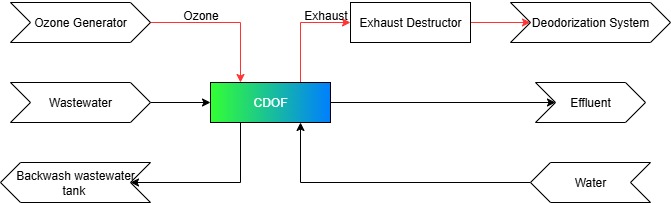

Process Flow for Treating Alcohol Production Wastewater

After alcohol production wastewater enters the pipeline via the lift pump, a high-efficiency injection device introduces ozone gas into the CDOF unit. Under the high-speed shearing action of the injection pump, the ozone gas is cut and compressed into micro-bubbles. Then the ozone efficiently and rapidly dissolved into the wastewater. The ozone-dissolved wastewater the mixed with a water quality modifier and enters the CDOF unit. Inside the reactor, the ozone molecules dissolved in the wastewater are rapidly converted into highly oxidative hydroxyl radicals (·OH, oxidation potential 2.8 V) through the heterogeneous catalysts. These hydroxyl radicals subsequently oxidize and decompose organic matter into H2O and CO2. During the pressure reduction process of the effluent from the CDOF reaction tank, cavitation-induced catalysis occurs. After two-stage catalytic reactions, the COD in the wastewater is gradually reduced to the required limit, and the effluent proceeds to subsequent treatment stages.

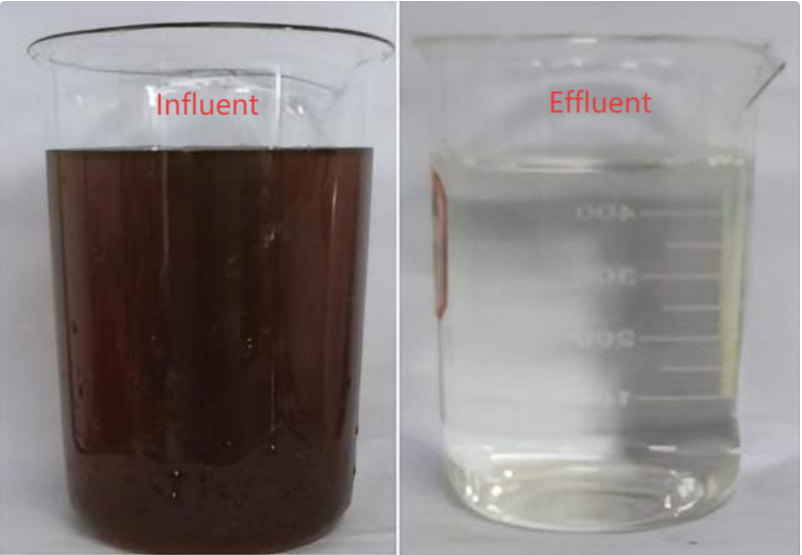

Treatment Performance

This innovative process has many advantages, including:

1. It is a stable, mature, and efficient treatment process, ensuring consistent compliance with effluent quality and avoiding secondary pollution.

2. The equipment features a compact design with a small footprint to meet on-site spatial constraints. It also adapts skid-mounted and modular designs for rapid installation and commissioning.

3. The equipment meets requirements for automated control and user-friendly operation. T incorporates automated design to minimize manual intervention, significantly reduce operational complexity.

4. The main unit and auxiliary equipment are designed for fully enclosed operation, preventing leakage of malodorous gases, thereby meeting on-site safety and environmental standards.

The new treatment process for alcohol production wastewater incorporates new technologies, methodologies, materials, and equipment. It enhances treatment efficiency, optimizes operational management, conserves energy, and significantly reduces both construction and operational costs, demonstrating great application prospects.