The Process of Treating Landfill Leachate

Landfill leachate primarily originates from the moisture inherent in the waste itself, as well as rainwater, snowmelt, and other liquids that enter the landfill. Under the influence of gravitational flow within the landfill, these liquids percolate through the waste layers and the covering material, resulting in the formation of high-pollutant substances, including organic matter, ammonia nitrogen, and heavy metals. The presence of these contaminants makes the treatment of landfill leachate particularly complex and challenging.

Difficulties of Treating Landfill Leachate

1. Significant variations in water quality and quantity: The water quality and quantity of landfill leachate are influenced by multiple factors, including waste type, landfill age, and rainfall, leading to considerable fluctuations that increase treatment complexity.

2. High organic concentration: Landfill leachate contains complex organic compounds at high concentrations, making steps like bio-degradation and chemical oxidation during treatment particularly challenging.

3. High levels of ammonia nitrogen and heavy metals: Ammonia nitrogen and heavy metals are two other major pollutants in landfill leachate. Their presence not only complicates the treatment process but also poses risks to the environment and human health.

Traditional Treatment Processes

Traditional processes primarily include physical, chemical, and biological methods. However, these processes exhibit several limitations, especially in treating high-concentration, refractory landfill leachate.

1. Physical Methods: Techniques such as sedimentation and filtration can only remove suspended solids (SS) and particulate matter (PM). They are ineffective at removing pollutants like dissolved organic matter and ammonia nitrogen.

2. Chemical Methods: Methods like the coagulation, sedimentation, and oxidation can remove some organic matter and ammonia nitrogen. However, the processes require large quantities of chemical agents, which not only increases treatment costs but may also cause secondary pollution.

3. Biological Methods: Methods like the activated sludge process and bio-membrane processes can degrade organic matter to some extent. Meanwhile, they exhibit poor efficiency at removing high concentrations of pollutants like ammonia nitrogen and heavy metals. Furthermore, the biological treatment process is easily affected by fluctuations in water quality and quantity, resulting in poor stability.

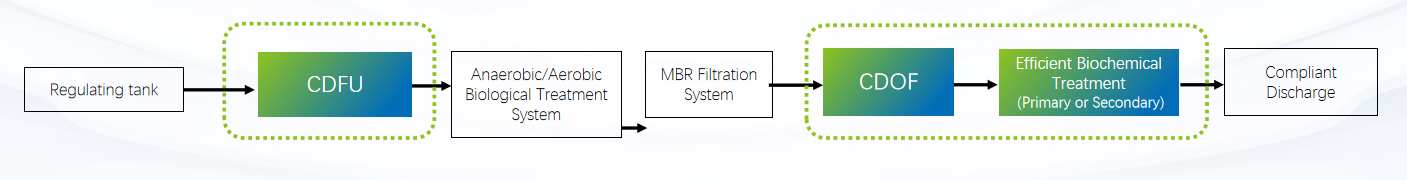

The new treatment process utilizes the Cyclonic Dissolved Ozone Flotation Unit (CDOF), demonstrating outstanding performance.

Principles of CDOF

CODF integrates multiple advanced technologies, including ozone multi-catalytic oxidation, hydrodynamic cavitation, and cyclonic gas flotation. Its core mechanism relies on ozone, under the effect of catalysts, generating highly reactive species such as hydroxyl radicals with strong oxidation. These reactive substances undergo redox reactions with pollutants (such as organic matter and ammonia nitrogen) in the landfill leachate. They break down large organic molecules into smaller ones, or even directly oxidize them into carbon dioxide and water, while simultaneously converting ammonia nitrogen into harmless substances like nitrogen gas, thereby achieving the goal of pollutant removal.

Advantages of the New Process

1. High Efficiency: After treatment by the CDOF unit, the chemical oxygen demand (COD) of the effluent can be reduced to below 400 mg/L, with a chromaticity of ≤ 30 and no unusual odor. When combined with a Biological Aerated Filter (BAF) for treating landfill leachate concentrate, the effluent quality can meet the GB16889-2008 standard.

2. Stable and Reliable: The new process demonstrates outstanding resistance to shock loads, effectively handling various complex water quality conditions and ensuring treatment efficiency remains at a high level. Furthermore, the effluent quality is consistently stable and reliable, meeting stringent discharge standards.

3. Environmentally-Friendly: The process features a concise and highly efficient design, relying primarily on physical methods as the core treatment approach. This avoids the use of chemical agents, reducing the risk of secondary pollution. Additionally, the system generates minimal oily sludge, significantly lowering the difficulty and cost of subsequent disposal.