New Treatment Process for Industrial Wastewater: Analysis of the combination of CDFU and CDOF

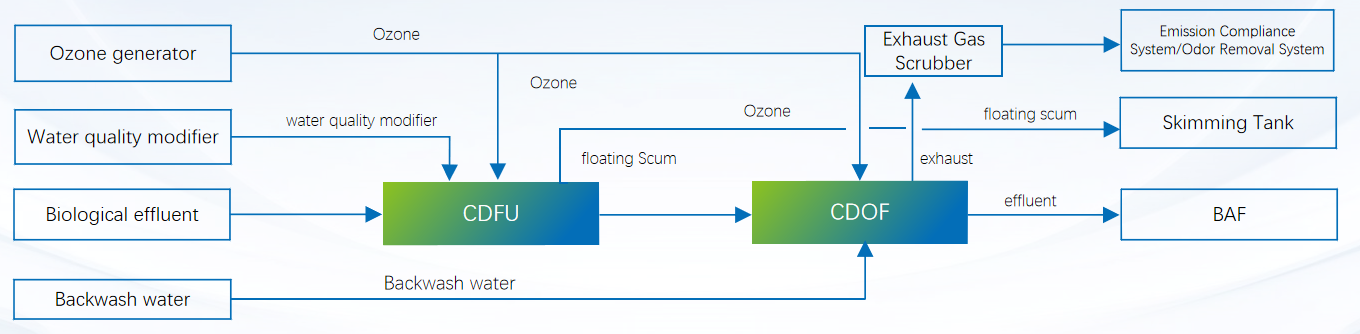

This integrated process is built around two core units: CDFU and CDOF. Industrial wastewater first enters the CDFU unit, where flocculation-air flotation technology rapidly and effectively separates a portion of the colloidal substances. Simultaneously, the introduced ozone reacts with some organic matter, achieving a preliminary reduction in the organic pollutant load. Subsequently, the wastewater flows into the CDOF unit, where catalytic ozone oxidation technology enables the further removal of remaining organic pollutants, ensuring the final effluent complies with stringent discharge standards.

Process Flow

Advantages

From the perspective of technological advantages, the integrated process of CDFU and CDOF demonstrates an extraordinary performance:

1. It integrates multiple patented technologies, establishing a unique position domestically and a leading stance internationally. Its robust technical prowess lays a solid foundation for the highly efficient operation of the process.

2. The multi-stage catalytic oxidation technology stands out as a key highlight, enhancing ozone oxidation efficiency by more than fourfold and enabling more effective decomposition of organic pollutants.

3. The process achieves remarkable results in eliminating wastewater odors and decolorization. It reduces chroma by over 90% and significantly improves effluent quality.

4. Insisting in green and environmentally-friendly principles, the process not only avoids generating secondary pollution, but also reduces sludge volume by more than 90%, aligning with the contemporary demands for sustainable development.

5. The highly integrated and skid-mounted design of the equipment shortens the process flow and substantially reduces the footprint.

6. The equipment is pressurized-sealed, ensuring high standards of safety, stability, and environmental protection.

Comparison

Compared to the traditional membrane + evaporation technology, the advantages of this combined process are even more prominent. In the traditional process, membrane and evaporators are highly prone to scaling and clogging, requiring frequent maintenance. This results in poor long-term operational stability and consistently high operation and maintenance costs. In contrast, the combined process utilizes patented membrane-free technology, which also does not generate concentrate. It effectively avoids scaling and blockage issues. What’s more, long-term stable operation is ensured through real-time multi-parameter automatic monitoring. The integrated process operates without relying on consumables and minimizes chemical usage, significantly reducing operation and maintenance costs. To sum up, it comprehensively outperforms traditional technologies in areas such as operational convenience, footprint, safety, environmental friendliness, and commissioning time.

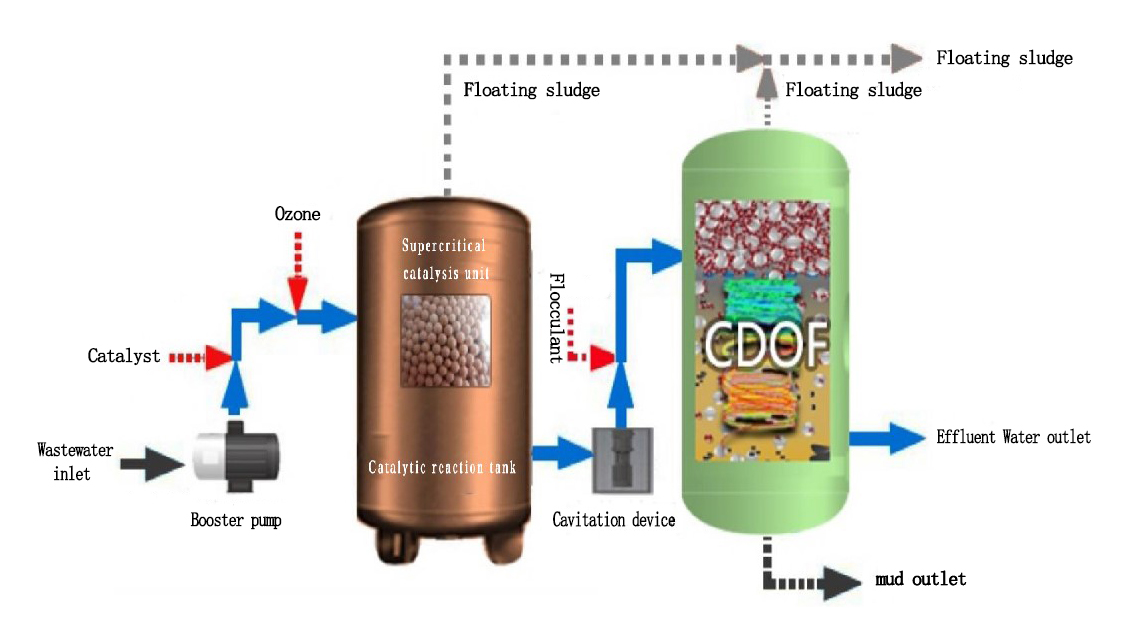

CDOF Workflow

Performance

It is worth mentioning that the effluent indicators of this combined process show exceptional performance, strictly complying with the Grade 1-B standards of GB 18918-2002. Specifically:

1. Chemical Oxygen Demand (COD) < 60 mg/L: This indicator reflects the level of contamination by reductive substances in the water. A lower value indicates fewer organic pollutants in the wastewater.

2. Five-Day Biochemical Oxygen Demand (BOD5) < 20 mg/L: BOD5 represents the amount of dissolved oxygen consumed by microorganisms to decompose biodegradable organic matter in the water. A lower value signifies good biodegradability of the wastewater and reduced environmental harm.

3. Suspended Solids (SS) < 20 mg/L: A lower SS content effectively prevents water turbidity and minimizes impact on aquatic organisms.

Leveraging its unique technical advantages, exceptional treatment efficiency, significant cost effectiveness, and outstanding effluent quality, the combination of CDFU and CDOF processes pioneers an innovative pathway for treating high-difficulty industrial wastewater. As environmental regulations continue to tighten and the demand for water resources recycling in industrial development grows, this innovative process is expected to have broader application and promotion in the field of industrial wastewater treatment. It will strongly propel industrial sustainability and drive continuous progress in environmental protection.