Mobile Wastewater Treatment Equipment: The Flexible Guardian of Water Environment

Amid the increasingly severe challenges of water scarcity and environmental pollution, wastewater treatment has become a crucial link in safeguarding the ecological environment. While traditional fixed wastewater treatment plants can achieve large-scale treatment, they are limited by factors such as site requirements and construction cycles, making it difficult to meet temporary and emergent wastewater treatment needs. Against this backdrop, mobile wastewater treatment equipment has emerged as a "flexible elite" in the field of wastewater treatment, thanks to its unique structural design and excellent performance. This article will take you to deeply understand which structures belong to mobile wastewater treatment equipment and what unique characteristics and advantages they possess.

I. What is Mobile Wastewater Treatment Equipment? An Analysis of Mainstream Structural Types

Mobile wastewater treatment equipment is not a single-structure device, but a general term for an integrated wastewater treatment system with mobile properties and rapid deployment capabilities. Its core feature is the high integration of core wastewater treatment units such as pretreatment, reaction, sedimentation, filtration, and disinfection onto a mobile carrier, enabling it to be put into use without large-scale civil engineering. Currently, the mainstream mobile structures on the market are mainly divided into the following two types:

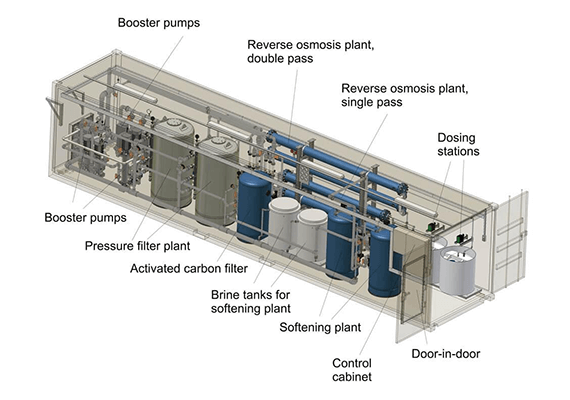

1. Container-type: Standardized "Wastewater Treatment Cabin"

This is the most widely used mobile structure at present. Its main body adopts 20-foot or 40-foot standard containers as the carrying carrier, with all wastewater treatment modules compactly integrated inside the container. The advantage of this structure is that it fully complies with global universal logistics and transportation standards, eliminating the need for additional special transportation permits. It can be quickly transported to the destination by various means of transportation such as trucks, ships, and trains. The interior is usually divided into functional areas such as a filtration chamber, reaction zone, sludge storage chamber, and control cabin, equipped with a coarse filter layer, pressure filter layer, biological reaction unit, dehydration module, and intelligent control system. Some equipment also has a waterproof layer coated on the inner wall of the container to ensure safe operation. Whether it is domestic wastewater treatment in remote rural areas or emergency wastewater treatment in industrial parks, container-type equipment can achieve "immediate transportation, immediate installation, and immediate use."

2. Modular-type: Flexible Assembled "Splicing Equipment"

Modular-type equipment designs different functional units of wastewater treatment (such as grille modules, anaerobic reaction modules, aerobic reaction modules, filtration and disinfection modules, etc.) into independent mobile modules respectively. During use, different modules can be flexibly combined to form a complete treatment system according to the wastewater volume, water quality, and treatment standards. The advantage of this structure lies in its strong scalability and adaptability. It can not only treat small-scale domestic wastewater but also meet the treatment needs of large-scale industrial wastewater through multi-module splicing. For example, in mine wastewater treatment projects, reaction modules can be gradually added according to the increase in wastewater treatment volume to achieve a step-by-step improvement in treatment capacity.

II. Core Characteristics of Mobile Wastewater Treatment Equipment

Compared with traditional fixed wastewater treatment plants, mobile wastewater treatment equipment exhibits many unique characteristics in design and operation, enabling it to adapt to diverse application scenarios:

1. High Portability and Rapid Deployment

Relying on standardized mobile carriers (containers) or modular design, the equipment can be quickly transported and installed without the need for long-term civil engineering like fixed treatment plants. Usually, after the equipment arrives at the site, it can be started and operated only by connecting the inlet and outlet pipes and switching on the power supply. The deployment cycle ranges from a few days to a few weeks, which is much shorter than the construction cycle of fixed treatment plants that takes several months or even years.

2. High Degree of Automation and Simple Operation

Modern mobile wastewater treatment equipment is generally equipped with an intelligent control system (such as a PLC control system), which can real-time monitor wastewater inflow flow, water quality parameters (COD, ammonia nitrogen, turbidity, etc.), and automatically adjust operating parameters such as aeration rate, reflux ratio, and chemical dosage to ensure stable treatment effects. The equipment does not require a large number of personnel on duty during operation, only regular maintenance is needed, which greatly reduces the operation difficulty and labor costs, and is especially suitable for remote areas or emergency scenarios lacking professional operators.

3. Diverse Treatment Processes and Wide Adaptability

The equipment can flexibly configure different wastewater treatment processes according to treatment needs, such as biological contact oxidation process, membrane bioreactor (MBR) process, sequencing batch reactor (SBR), anaerobic-aerobic combined process, etc., which can treat various types of wastewater such as domestic wastewater, industrial wastewater, breeding wastewater, and mine wastewater. At the same time, the treatment capacity of the equipment can range from a few cubic meters per day to several thousand cubic meters per day, which can meet the treatment needs of different scales.

4. Energy Conservation and Environmental Protection, with Less Secondary Pollution

Mobile equipment generally focuses on energy conservation and consumption reduction in design, adopting high-efficiency aeration equipment, energy-saving motors, etc., to reduce operating energy consumption. At the same time, the sludge generated during the treatment process has a significantly reduced water content after being treated by the dehydration module, which is convenient for subsequent transportation and disposal; the disinfection link mostly adopts green disinfection methods such as ultraviolet disinfection, avoiding secondary pollution that may be caused by chemical disinfection agents.

III. Outstanding Advantages of Mobile Wastewater Treatment Equipment

The unique structure and characteristics endow mobile wastewater treatment equipment with irreplaceable advantages, making it play an important role in many fields:

1. Strong Emergency Response Capability to Effectively Deal with Sudden Pollution

After natural disasters (such as floods and earthquakes), fixed wastewater treatment facilities may be damaged or overloaded, leading to direct discharge of wastewater and environmental pollution. At this time, mobile wastewater treatment equipment can quickly rush to the scene to build a temporary wastewater treatment system, ensuring that wastewater is discharged up to standard, and preventing the spread of epidemics and environmental degradation. In addition, during the maintenance of enterprise wastewater treatment facilities, mobile equipment can be used as a temporary alternative to avoid enterprises shutting down due to inability to treat wastewater and prevent sudden pollution incidents.

2. Adaptable to Decentralized Scenarios, Solving Wastewater Treatment Problems in Remote Areas

In areas with scattered population distribution and imperfect infrastructure such as rural and mountainous areas, the construction of fixed wastewater treatment plants is costly and has low utilization rates. Mobile wastewater treatment equipment can flexibly deploy small-scale treatment systems according to the village scale and wastewater discharge volume, realizing on-site treatment and on-site discharge of wastewater, and effectively solving the "last mile" problem of wastewater treatment in remote areas. For example, in remote mountain villages, container-type MBR mobile equipment can achieve zero direct discharge of wastewater, effectively protecting the local water environment.

3. Reducing Investment Costs and Improving Resource Utilization

Fixed wastewater treatment plants require a large amount of capital investment for civil engineering, equipment installation, etc., while mobile equipment does not require civil engineering investment, resulting in lower initial investment costs. At the same time, for temporary projects (such as temporary construction camps and large-scale event venues), mobile equipment can be transferred to other sites for continued use after the project is completed, avoiding resource waste; for scenarios with large fluctuations in treatment volume, the rational allocation of resources can be achieved by adjusting the operating status of the equipment or increasing/decreasing modules.

IV. Conclusion

As an innovative solution in the field of wastewater treatment, mobile wastewater treatment equipment, relying on flexible structural designs such as container-type and modular-type, as well as outstanding advantages such as portability and efficiency, high degree of automation, and wide adaptability, plays an irreplaceable role in scenarios such as emergency rescue, remote area governance, and temporary project treatment. With the continuous advancement of technology, mobile wastewater treatment equipment will develop in a more intelligent, energy-saving, and efficient direction in the future, further improving the efficiency of water resource recycling and providing stronger support for safeguarding the ecological environment.