3 Steps to Purify Refinery Wastewater: Grille → DAF → Biochemical Process

During the production of gasoline, diesel and other petroleum products, oil refineries generate large volumes of wastewater with complex compositions, containing oil contaminants, suspended solids and toxic organic substances. Direct discharge of such wastewater would cause severe pollution to soil and water sources.

In fact, the core treatment process for refinery wastewater is not complicated. Three key steps—grille filtration → dissolved air flotation → biochemical treatment—can gradually purify turbid wastewater until it meets discharge standards. Let's break down each step in detail.

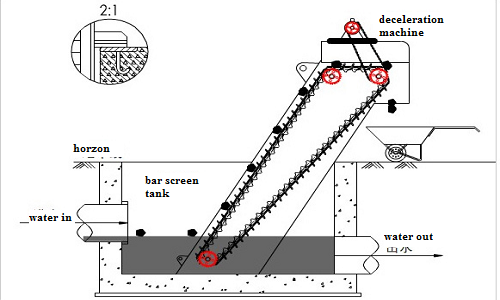

Step 1: Grille Filtration – The First "Sieve" for Wastewater

Grille filtration serves as the pretreatment stage of refinery wastewater treatment, acting like a sieve for wastewater.

Refinery wastewater often contains various large debris, such as rags, plastic pieces, welding slag and solid particles shed during production processes. If these impurities enter subsequent treatment equipment, they may easily clog pipelines, damage pumps and disrupt the operation of the entire treatment system.

The working principle of a grille is simple: it is a filtering device composed of a series of parallel metal bars. When wastewater flows through the grille, large-sized suspended solids are intercepted by the bars. Workers regularly clean these trapped residues, which pre-purifies the wastewater and reduces the load on subsequent treatment units.

After grille filtration, large impurities are removed, but the wastewater still contains fine suspended solids and high concentrations of oil contaminants, requiring further treatment in the next step.

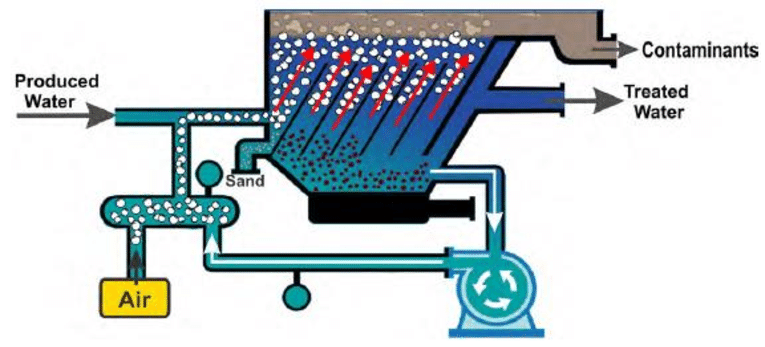

Step 2: Dissolved Air Flotation (DAF) – Making Oil Contaminants Float to the Surface

The core objective of this step is to remove oil substances and fine suspended solids from wastewater, making it one of the most critical stages in refinery wastewater treatment.

Oil contaminants in refinery wastewater are categorized into free oil, dispersed oil and emulsified oil. Emulsified oil, in particular, consists of tiny oil droplets that are difficult to separate from water as they are fully mixed. The principle of DAF is to inject a large number of micro-bubbles into the wastewater, which attach to the surfaces of oil droplets and fine suspended solids.

Carried by the bubbles, these contaminants float upward and eventually form a layer of scum on the water surface. Workers scrape off the scum, effectively separating most oil contaminants and suspended solids from the wastewater.

After DAF treatment, the turbidity of wastewater drops significantly, and the oil content is reduced to a relatively low level. However, the water still contains dissolved toxic organic substances such as phenols and benzenes, which need to be addressed in the third step.

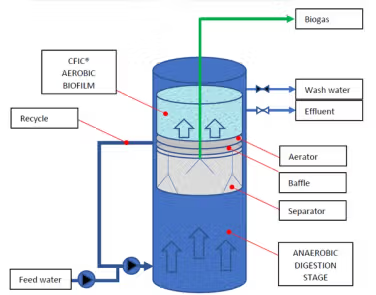

Step 3: Biochemical Treatment – Microorganisms "Consume" Dissolved Contaminants

Biochemical treatment is the core stage of refinery wastewater purification, relying on the principle of microbial degradation.

Although the wastewater appears clear to the naked eye after the first two steps, it still contains large amounts of organic matter that can be utilized by microorganisms. The biochemical treatment tank is cultivated with a specialized "microbial army", including aerobic bacteria and anaerobic bacteria.

In an aerobic environment, aerobic bacteria feed on organic matter in the wastewater, breaking it down into carbon dioxide, water and harmless inorganic salts through metabolism. For some refractory organic substances, anaerobic digestion is applied: anaerobic bacteria decompose large-molecule organic compounds into small-molecule ones, facilitating further degradation by aerobic bacteria in subsequent processes.

This process is like performing a deep cleaning on the wastewater—toxic and harmful substances dissolved in the water are "consumed" by microorganisms, and key pollution indicators (such as COD and ammonia nitrogen) are reduced to meet discharge standards.

Conclusion

From grille filtration for intercepting large impurities, to dissolved air flotation for separating oil and fine suspended solids, and then to biochemical treatment for degrading dissolved contaminants, these three interconnected steps form the basic process for refinery wastewater treatment.

In practice, refineries may add advanced treatment stages such as activated carbon adsorption and membrane filtration before or after these three steps, depending on the actual water quality. Nevertheless, grille filtration → dissolved air flotation → biochemical treatment remains the most fundamental and essential "purification package". It is this set of processes that enables refineries to produce energy products while protecting the ecological environment.