Ozone-Based Advanced Oxidation for Industrial Wastewater

1. The Escalating Problem of Industrial Wastewater Pollution

As industrialization continues to advance, water pollution resulting from the discharge of industrial wastewater in processes such as boiler operations, printing and dyeing, desulfurization, and pharmaceuticals has become an increasingly pressing concern. Global statistics indicate that over 2.5 million tons of harmful substances are discharged into water sources annually, with industrial wastewater being one of the primary contributors to pollution during manufacturing activities.

Industrial wastewater often contains substantial amounts of organic compounds, heavy metals, and micropollutants, posing serious risks to both environmental and human health. For example, organic pollutants decrease water's natural purification capacity, heightening the pollution load and, because many of these compounds are toxic, they accumulate over time, causing irreversible damage to ecosystems. Given these potential dangers to aquatic life and human well-being, there is an urgent need to develop effective wastewater treatment technologies.

2. Limitations of Traditional Treatment Methods

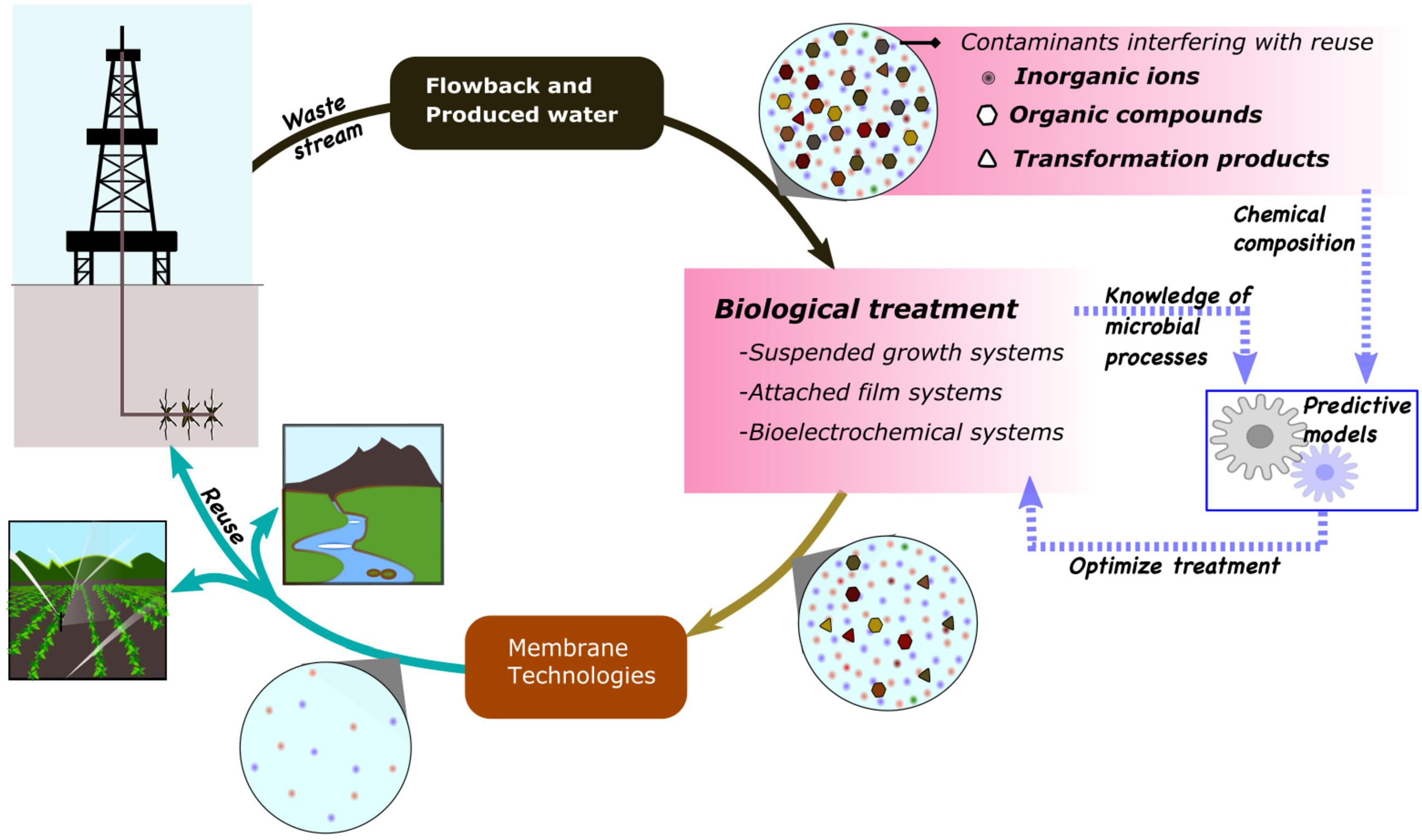

Traditional methods for industrial wastewater treatment include biological, physical, and chemical approaches. Biological methods rely on microbial metabolism to break down pollutants but are highly sensitive to changes in environmental conditions. These methods can lead to microbial inactivation, especially when treating wastewater from industrial areas with complex compositions, resulting in low mineralization of organic waste. Additionally, biological treatments typically require large land areas and are not well-suited for the increasingly complex nature of industrial wastewater.

Figure 1. Biological method

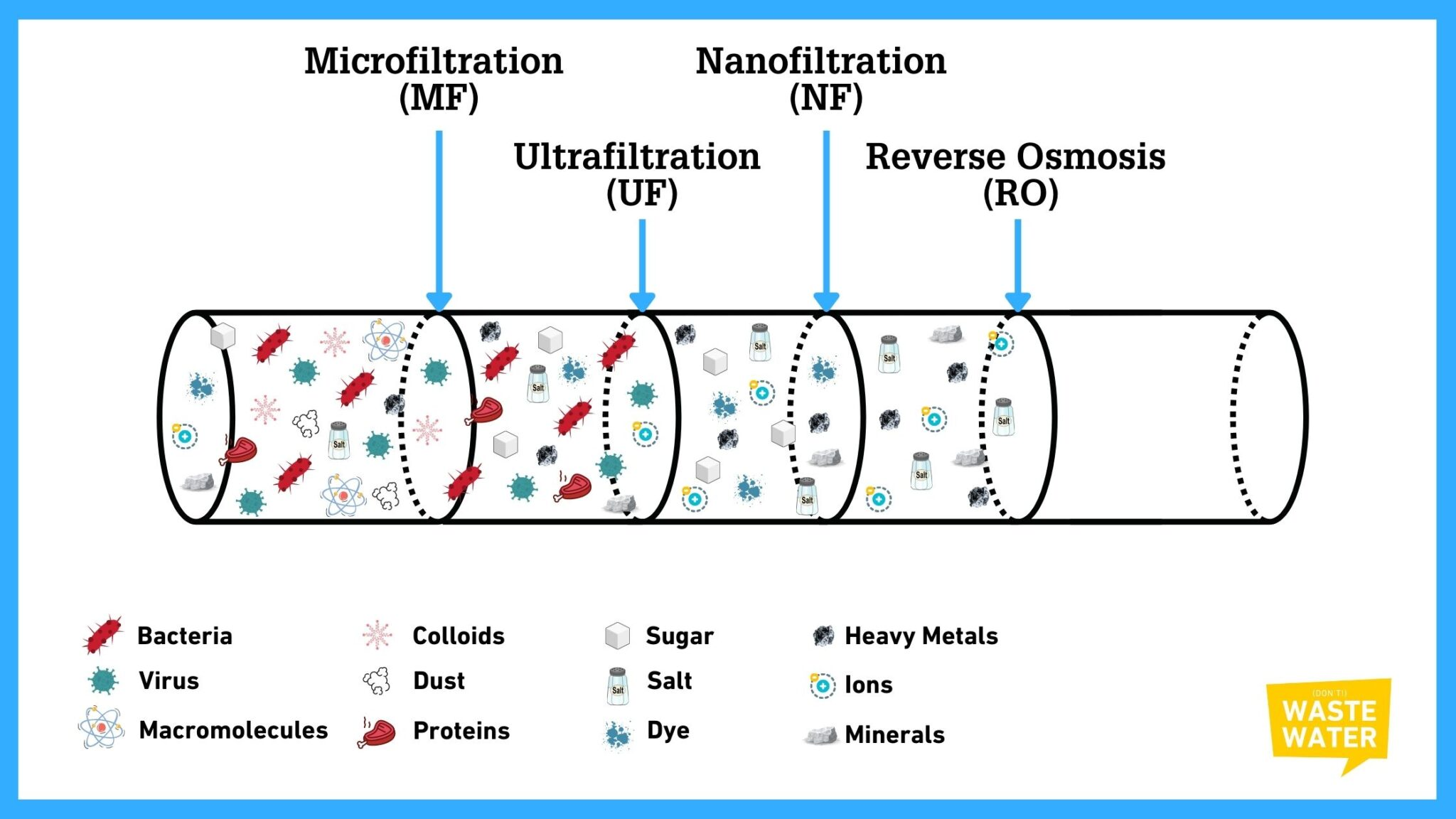

Physical treatment methods, such as adsorption and membrane filtration, are also commonly used. Adsorption removes organic pollutants through physical means, transferring pollutants rather than breaking them down chemically or biologically. While adsorption can be effective, challenges such as the need for regeneration of the adsorption material and the secondary treatment of pollutants hinder its widespread use. Membrane filtration is effective at separating contaminants in wastewater but faces significant issues, particularly in the treatment of highly polluted waters, such as those containing oil or high COD (chemical oxygen demand). Membrane fouling, which severely impedes efficiency, is a key issue and often requires additional treatment steps to manage.

Figure 2. Membrane method

3. The Promise of Chemical Treatments and Ozone Technology

Chemical treatment methods, including neutralization, precipitation, and advanced oxidation processes (AOPs), are known for their efficiency, speed, and adaptability. These methods are particularly useful for treating wastewater with high toxicity, high pollutant concentrations, or substances that are difficult to degrade. Among various chemical technologies, ozone treatment has gained significant attention for its effectiveness in breaking down organic compounds and removing heavy metals.

Ozone treatment works by utilizing ozone’s powerful oxidative properties to decompose harmful substances, thereby improving water quality and reducing environmental impact.

4. Advancing Ozone Treatment: Catalytic Ozonation

A notable advancement in ozone technology is catalytic ozonation, which involves the addition of catalysts to accelerate the decomposition of ozone into reactive oxygen species (ROS). This approach offers better efficiency across a range of pH values, enhances ozone utilization, and increases pollutant removal efficiency while also lowering operational costs. Catalytic ozonation addresses some of the challenges faced by traditional ozone AOP methods and holds significant potential for further development.

5. Types of Catalytic Ozonation: Homogeneous vs. Heterogeneous

Catalytic ozonation can be divided into two main types based on the catalysts used: homogeneous and heterogeneous. In homogeneous catalytic ozonation, metal ions, including transition metals such as Mn, Fe, Al, Co, and Ce, serve as catalysts. On the other hand, heterogeneous catalytic ozonation involves the activation of ozone by catalysts that are supported on materials with high surface areas and good stability, such as metal oxides and other stable carriers. Combining these two approaches enhances both ozone utilization and catalytic efficiency, reduces catalyst loss, and allows for the reuse of catalysts, ultimately lowering treatment costs.