Oilfield Produced Water (OPW): Characteristics, Environmental Risks, and Advanced Treatment Technologies

The Role of Oil and Gas in Modern Industry

The oil and gas industry plays a pivotal role in the 21st century, driving modern civilization through its vast contributions to energy production, manufacturing, and various other sectors. As a major source of energy, petroleum's demand continues to rise due to its widespread use across industries. To meet this growing demand, exploration and production activities have expanded significantly. However, this process comes with environmental challenges, particularly in the form of wastewater generated during oil and gas extraction.

What Is Oilfield Produced Water (OPW)?

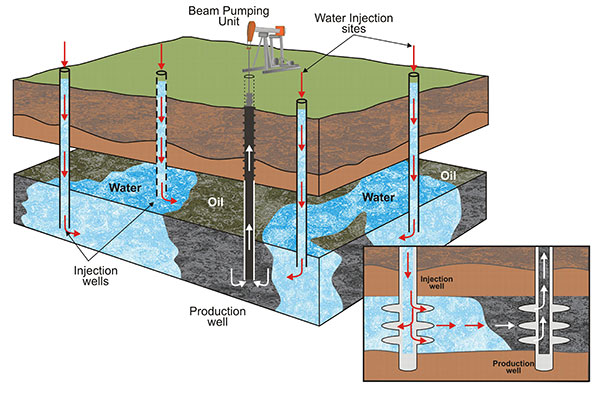

Oilfield produced water (OPW), commonly known as produced water, is an unavoidable byproduct of oil and gas extraction. It refers to the contaminated water that comes from beneath the Earth's surface during exploration and production. OPW typically consists of naturally occurring formation water and injected water used for reservoir pressure maintenance and to enhance oil mobility.

OPW is the largest source of wastewater in the oil and gas industry. Globally, it is produced in volumes three times greater than the amount of oil and gas extracted. For every barrel of crude oil produced, 2-3 barrels of OPW are generated. Gas reservoirs, in particular, produce wastewater at a rate ten times higher than oil reservoirs. As oilfields mature, this ratio is expected to rise further, with global OPW production currently estimated at around 250 million barrels per day, potentially reaching 605 million barrels per day in the future.

Factors Influencing OPW Generation

Several factors affect the amount and composition of OPW produced, including:

Reservoir Characteristics: The type of formation (homogeneous vs. heterogeneous) and its lifetime influence the volume of produced water.

Production Techniques: Oil drilling methods (vertical or horizontal), well completion strategies, and water flooding during secondary or tertiary oil recovery all play a role.

Technology and Production Rate: The rate of extraction and the technology used in the process also determine the volume of wastewater generated.

OPW contains a complex mix of organic and inorganic compounds. These include dissolved and dispersed oil, hydrocarbons, hydrogen sulfide, carbon dioxide, heavy metals, and traces of organic acids and inorganic salts. This composition makes OPW highly hazardous and capable of causing significant environmental damage, including soil erosion, water contamination, and disruption of local ecosystems.

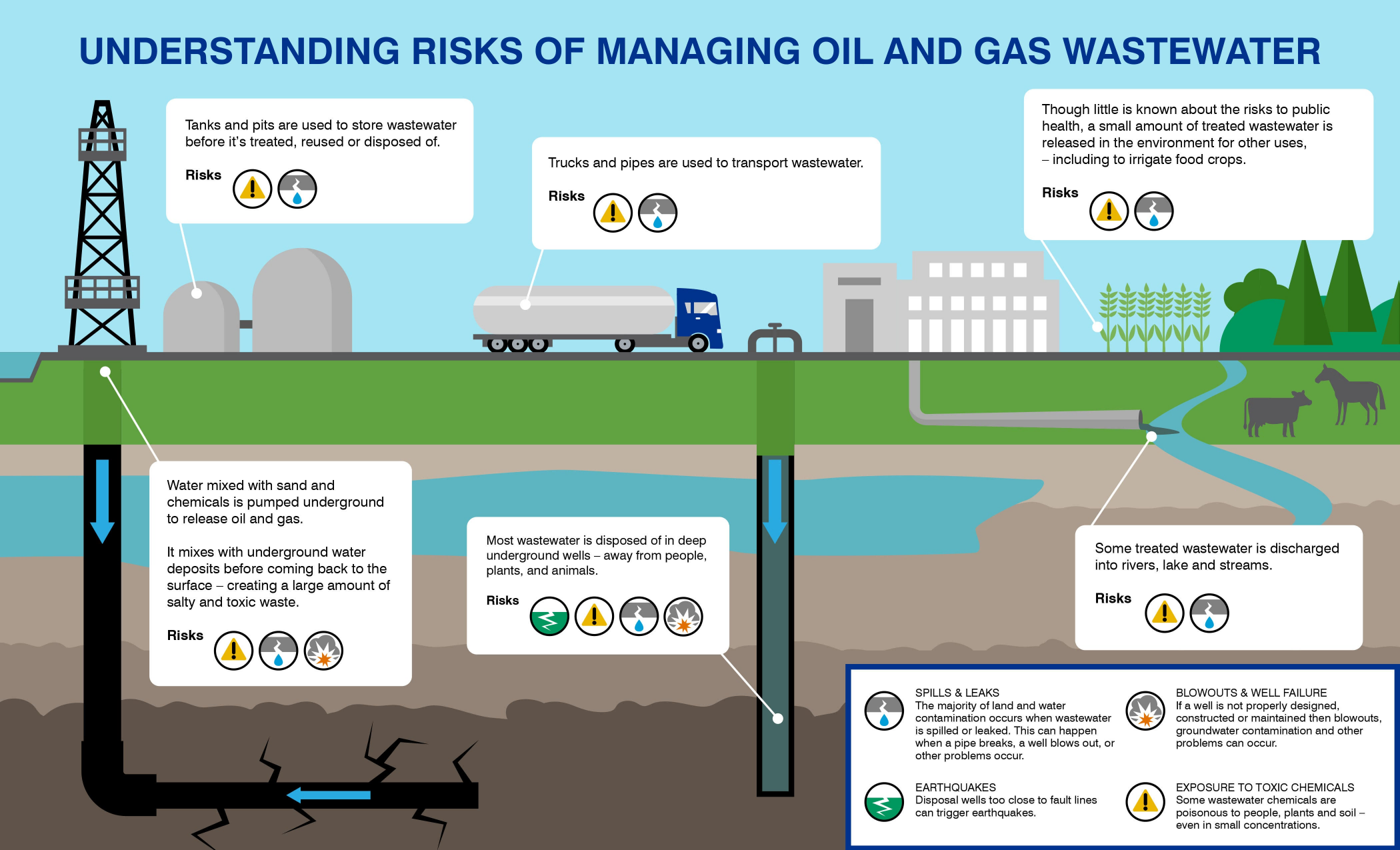

Environmental Risks of OPW

The disposal of OPW poses serious environmental challenges. The presence of toxic elements such as heavy metals, hydrocarbons, and hydrogen sulfide can have detrimental effects on both terrestrial and marine ecosystems. Some of the major environmental risks associated with OPW include:

Toxic Salts: High concentrations of salts can disrupt the salinity balance of water bodies, leading to fish kills and overall ecological disturbances.

Hydrocarbons and Hydrogen Sulfide: These substances can float on the water's surface, raising biochemical oxygen demand (BOD) and reducing oxygen levels, which in turn harms aquatic life.

Heavy Metals: OPW contains higher concentrations of heavy metals compared to seawater. While these metals may be diluted in large water bodies, they can still cause long-term environmental damage.

Radionuclides: The presence of radioactive materials in OPW can pose serious health risks to humans through external or internal radiation exposure.

Chemicals from Drilling Operations: The chemicals used in drilling and oil recovery processes can also be harmful to both animals and marine environments.

Given these risks, it is imperative that OPW undergo treatment before being released into the environment.

Treatment Methods for OPW

Treating OPW is essential to mitigate its harmful effects. Various treatment methods are employed depending on the specific characteristics of the wastewater, including its composition and volume. The primary goals of treatment are to remove suspended solids, oil emulsions, and toxic compounds such as heavy metals and hydrocarbons.

Common Treatment Techniques

Gravity Separation: This is the most common treatment method for OPW, often enhanced by skimming techniques to remove floating oil.

Dissolved Air Flotation (DAF): Effective for treating produced water with smaller oil droplets, DAF involves the addition of air to create bubbles that help separate oil from water.

Membrane Filtration: Membrane technologies are highly efficient in removing contaminants, though challenges such as membrane fouling and secondary waste generation need to be addressed.

Thermal Treatment: While effective, thermal methods are energy-intensive and may not be sustainable due to high operational costs.

Chemical Precipitation and Demulsification: These methods help remove dissolved salts, heavy metals, and emulsified oil, often used based on economic considerations and the availability of chemicals.

Biological Treatment: Biological processes like Activated Sludge Systems (CAS), Sequencing Batch Reactors (SBR), and Membrane Bioreactors (MBR) offer cost-effective solutions, though they may generate higher quantities of secondary waste.

Sustainable Solutions and Reuse of Treated OPW

A promising approach is to reuse treated OPW, either by reinjecting it into mature oilfields to enhance oil recovery or by using it for other industrial processes. This not only helps mitigate the environmental impact but also addresses water scarcity by recycling wastewater. As technologies advance, the goal is to develop more efficient, cost-effective methods for OPW treatment, focusing on both environmental protection and resource recovery.

Conclusion

The oil and gas industry has a significant environmental responsibility when it comes to managing the byproducts of exploration and production, particularly OPW. Effective treatment technologies are essential to minimize the harmful effects of OPW on ecosystems and human health. As the industry continues to evolve, it is crucial that both regulatory frameworks and technological innovations keep pace to ensure that OPW is handled in a way that minimizes its environmental footprint while maximizing the potential for reuse and recovery.