The Influence of Garbage classification on the Treatment Process of Landfill Leachate

Garbage classification, collection, and treatment form the essential foundation for proper waste disposal and resource recovery, serving as the critical pathway toward waste reduction, resource utilization, and harmless treatment. This holds a significant meaning for safeguarding public health and enhancing environmental sanitation.

Currently, most cities categories domestic waste into four main types: recyclable waste, kitchen waste, residual waste (also known as dry waste), and hazardous waste. To be more specific, recyclable waste is processed through a recycling and utilization system for renewable resources, while kitchen and residual waste are treated in a garbage treatment system. Normally, hazardous waste will be recycled independently or go into hazardous waste treatment, ensuring it will be treated properly.

Landfill leachate, a byproduct of waste classification and disposal processes, represents a form of secondary pollution and is classified as high-concentration organic wastewater. Its quality and quantity exhibit significant variability, influenced by multiple factors including waste composition, local environmental conditions, and precipitation levels. The landfill leachate treatment industry in China has been developed healthily for many years. Nowadays, hundreds of landfill leachate treatment facilities have been built. Garbage classification is positively promoted, which has a great influence on landfill leachate quantity, quality and treatment process. Effective garbage classification must be coupled with dedicated landfill leachate treatment.

1. The Influence of Garbage Classification on the Output of Leachate.

Landfill leachate primarily consists of inherent moisture from waste itself and external water ingress (e.g., rainfall, snowfall). The leachate volume of the waste incineration plant and kitchen waste treatment plant is basically unaffected by the rainfall and snowfall. The separation of dry and wet garbage reduces water content in garbage directed to incineration plants and landfills, consequently decreasing landfill leachate generation.

With the progressive implementation of garbage classification initiatives, residents are gradually adopting proper waste disposal practices. Open-type waste collection bins and outdated transport vehicles are being phased out and replaced with enclosed systems. At the same time, the government has been constantly strengthening supervision on all stages of waste handling - temporary storage, collection, transportation, treatment, and final disposal. These classification measures have also contributed to reducing leachate generation from external water infiltration.

Analysis of Wastewater Generated from Classified Waste Treatment Processes:

(1) Recyclables refer to waste that is suitable for recovery and recycling. This type of waste itself does not produce water. During the stage of recovery and reuse, some fresh water is used, resulting in wastewater. However, the water quality is relatively good and normally does not fall under the category of landfill leachate.

(2) Hazardous waste refers to waste containing heavy metals or toxic substances harmful to human health, or waste that poses actual/potential risks to the environment. During the treatment and disposal process, a small amount of wastewater is generated. Its water quality differs significantly from traditional landfill leachate, requiring different treatment processes. Generally, this waste is not classified as landfill leachate.

(3) Kitchen waste, also known as wet waste, includes food scraps such as leftovers, vegetable roots and leaves, fruit peels, and other organic kitchen refuse. This type of waste is characterized by high organic content, rapid decomposition, and low calorific value. Conventional disposal methods like landfill and incineration cannot provide effective treatment. Currently, the mainstream treatment process in China involves two major procedures “pretreatment and anaerobic digestion”. The de-watering of anaerobic digestion biogas residue produces a large amount of biogas slurry, which has similar water to traditional landfill leachate and poses considerable treatment challenges. With the progress of garbage classification, wet waste treatment facilities have been constructed and operated. The volume of biogas slurry requiring treatment is expected to increase dramatically. In addition, its proportion in landfill leachate treatment will keep growing. The treatment of anaerobic digestion biogas slurry is a hot topic as well as a difficult point in the landfill leachate treatment industry.

(4) Residual waste, also known as dry waste, refers to hard-to-recycle waste which do not fall in the previous category including bricks, tiles, ceramics, waste paper and food packaging. Currently, this type of waste is still processed using traditional treatment methods (landfilling and incineration). As a result of the implementation of garbage classification, the quantity of waste that finally goes into the landfill and incineration plant has reduced. The volume of leachate generated will also decrease compared to the period before waste classification was implemented.

2. The Influence of Garbage Classification on Leachate Water Quality

The major characteristics of traditional landfill leachate water quality are as follows:

(1) The components of pollutants are complex, the water quality fluctuates greatly, and the treatment is difficult.

(2) The concentrations of organic matter and ammonia nitrogen are high, and refractory organic matter accounts for a certain proportion.

(3) High content of heavy metal and salinity.

After the implementation of garbage classification, the landfill leachate primarily comes from the wet waste biogas slurry after anaerobic digestion and wastewater generated from dry waste incineration and landfilling.

The biogas slurry produced from the anaerobic digestion and dewatering of wet waste exhibits water quality similar to traditional landfill leachate, but there are also differences:

(1) Wet waste contains kitchen waste which has high oil content, resulting in a relatively high oil content in the biogas slurry.

(2) Whether medium-temperature or high-temperature anaerobic digestion is used for wet waste, the resulting biogas slurry after dewatering will have a higher temperature than conventional landfill leachate.

(3) Due to the complex composition of wet waste, the biogas slurry produced after anaerobic dewatering tends to form floating scum and has high suspended solids content, particularly with a significant presence of fibrous impurities.

(4) Garbage classification separates wet waste from heavy-metal-containing waste, leading to a reduction in heavy metal content in biogas slurry.

For leachate generated from waste incineration plants and landfills, the separate treatment of organic food waste has reduced the amount of organic material entering these facilities. As a result, the concentration of organic pollutants in the leachate has significantly decreased. In aging landfills, the imbalance in the carbon-to-nitrogen (C/N) ratio of leachate becomes even more pronounced. Similarly, since heavy-metal-containing waste is now separately collected before entering incineration plants and landfills, the heavy metal content in the leachate has also been reduced.

3. The Influence of Garbage Classification on Leachate Treatment Process

(1) The influence on the wastewater treatment process of the organic waste treatment plant.

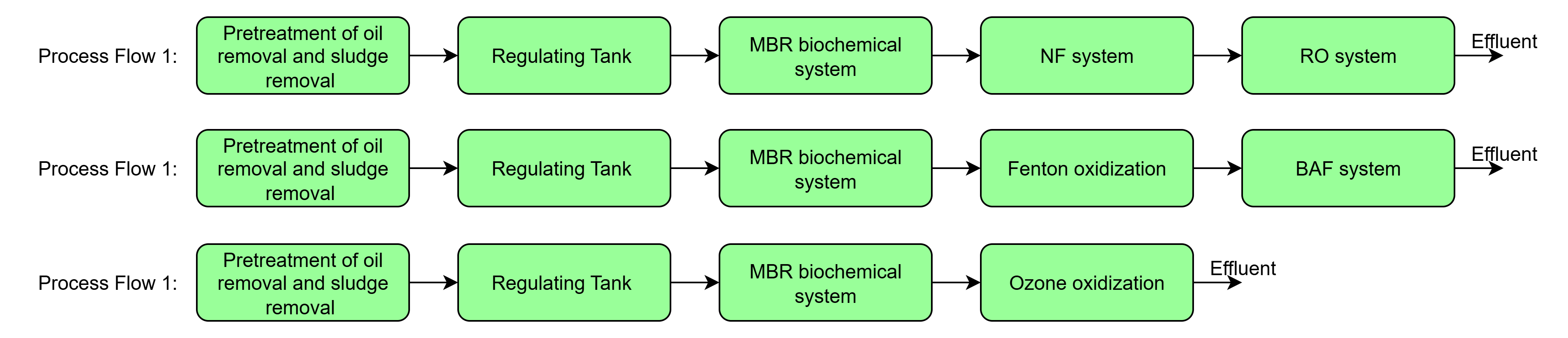

Organic waste treatment plants primarily handle perishable waste such as kitchen waste. Some Chinese cities pioneered the separate collection and treatment of catering waste as early as 2000. For the anaerobic biogas slurry produced by these catering waste treatment plants, three main treatment processes are available depending on different effluent discharge standards:

With the implementation of waste classification policies, various regions have strengthened the segregated collection of kitchen waste. Normally, kitchen waste is stored in receiving hoppers, where it generates high-concentration leachate (with COD levels as high as 60,000 mg/L). Additionally, the COD of biogas slurry from dry anaerobic digestion and dewatering of kitchen waste is higher than that from wet anaerobic digestion of catering waste, typically reaching around 30,000 mg/L.

If an organic waste treatment plant only handles kitchen waste, the wastewater treatment process should include an anaerobic system. If organic waste treatment needs to handle both catering waste and kitchen waste, a part of the high concentration leachate or biogas slurry can enter the wet anaerobic digestion of catering waste, while the other part of the high concentration leachate or biogas slurry can be a carbon source, adding to the anaerobic stage of the wastewater treatment.

a. Pretreatment System

The oil content rate of catering waste is relatively high. Through the pretreatment of oil removal, there is still a partial oil dispersed in the wastewater treatment system. Additionally, the components of catering waste and kitchen waste are complex; the biogas slurry after anaerobic digestion has a relatively high content of scum. Particularly when dry anaerobic biogas slurry enters the wastewater treatment section, its solid content is around 2% forming floating scum easily. However, oil, floating scum and other impurities will influence the normal operation of the subsequent stage of the wastewater treatment system. These substances must be removed in the pretreatment system. Thus, the proper selection of the pretreatment process is crucial.

b. The Temperature of Influent Biogas Slurry

The biogas slurry produced from medium-temperature or high-temperature anaerobic digestion of catering and kitchen waste maintains a higher temperature than conventional leachate. However, temperatures that are either too high or too low can adversely affect microbial activity, directly compromising the overall treatment efficiency of the system.

c. Carbon Source

The COD of biogas slurry from catering and kitchen waste after anaerobic digestion and dewatering is significantly influenced by the anaerobic system's performance. In China, the actual operational results of anaerobic treatment technologies for such waste vary substantially, leading to considerable differences in the COD levels of the resulting biogas slurry. However, the total nitrogen and ammonia nitrogen content in the slurry are more strongly affected by the waste source characteristics. In some cities, the total nitrogen in anaerobic biogas slurry can reach as high as 4,000 mg/L, causing severe carbon deficiency in MBR systems.

d. The Selection of Ultra-filtration Membrane

The anaerobic biogas slurry generated from wet waste contains high levels of impurities, particularly fibrous and lightweight materials. These substances cause severe fouling in ultrafiltration membranes of the MBR system, significantly increasing on-site operational and maintenance demands. Currently, the tubular ultrafiltration membranes commonly used in China pose challenges because membranes are difficult to clean effectively and prone to membrane tube damage during the cleaning procedure which influences the normal operation. In contrast, submerged ultrafiltration membranes offer substantially simpler cleaning and maintenance requirements and are projected to dominate market adoption in the future.

(2) The Influence on Landfill Leachate Treatment Process

After the implementation of garbage classification, the amount of garbage going into the landfill has reduced dramatically. Wet waste does not go into landfills any more, significantly decreasing the water content of garbage. The decrease in landfill leachate production and the reduction in organic content within the waste have led to significant changes in leachate water quality. This substantially impacts the existing leachate treatment processes at the landfill, specifically reflected in the following aspects:

a. The decrease in leachate production has resulted in excessively long hydraulic retention time in the existing landfill regulating tank. The biodegradable organic matter undergoes thorough degradation in the regulating tank, which adversely affects subsequent biological nitrogen removal processes.

b. The existing leachate treatment system is redundant, resulting in some equipment being in an idle state, such as the membrane system, cooling system, and sludge dewatering system.

c. With the extension of landfill time, the organic pollutants in landfill leachate decrease year by year, resulting in a severely imbalanced C/N ratio. Normally, landfills will combine the fresh leachate generated from fresh garbage with leachate from aging landfill, which will enhance nitrogen removal efficiency in leachate treatment and save operational costs. As the implementation of the garbage classification, the organic content of fresh garbage decreases, which leads to the low organic content of generated leachate. The decrease in organic content makes the carbon source insufficient for efficient denitrification. In actual operation, fresh carbon sources such as glucose or sodium acetate must be added to ensure effective nitrogen removal. Continuously adding a large number of carbon sources compromises the stability of the entire leachate treatment system and reduces its shock-load resistance.

d. The reduction of landfill leachate results in a decrease in the concentration of production.

(3) The Influence on Incineration Plants Treatment Process

Similar to the situation of landfills, garbage classification significantly reduced both the volume of waste entering incineration plants and the organic content of the water. This has led to a substantial decrease in both the quantity of leachate and its organic concentration at incineration plants. The influences of garbage classification on the incineration plants’ existing leachate treatment process are as follows:

a. Figure 2 shows the current common leachate treatment processes adopted in domestic waste incineration plants. Due to the significant reduction in organic content, the anaerobic system in the original process flow can be omitted. The decommissioning of this anaerobic system has consequently led to the shutdown of ancillary facilities such as the biogas treatment system.

Figure 2. Common Leachate Treatment Processes in Domestic Incineration Plants

b. The double changes in leachate quantity and quality have triggered a series of operational impacts. For instance, 1. The existing MBR bio-reaction tank has excessive capacity, leading to extended hydraulic retention time and reduced activity of activated sludge. 2. The aeration blowers are now excessive, making dissolved oxygen control difficult with jet aeration systems. 3. Internal recycling ratios have decreased. 4. The cooling system now operates intermittently or remains idle. 5. Reduced sludge production has caused some sludge treatment equipment to be underutilized.

c. With diminished flow to the advanced treatment systems, portions of the membrane systems now operate below capacity. While this decreases chemical consumption, overall leachate treatment operating costs are consequently reduced.

d. The reduction in leachate volume leads to decreased concentrate production, efficiently resolving the long-standing concentrate disposal challenge.

4. Other Influences of Garbage Classification on Leachate Treatment

(1) Changes in Emission Standards

Following garbage classification, significant changes have occurred in both quantity and quality of leachate at landfill sites and incineration plants. Consequently, treatment processes have undergone corresponding modifications, with anticipated revisions to discharge standards. Current leachate effluent quality standards in China include: Integrated Wastewater Discharge Standard (GB 8978), Standard for Wastewater Discharge into Urban Sewerage Systems (GB/T 31962), Standard for Pollution Control on Municipal Solid Waste Landfill (GB 16889), Water Quality Standards for Urban Wastewater Reuse - Industrial Uses (GB/T 19923).

Future revisions to discharge standards will better align with industry characteristics and development needs, thereby promoting sustainable sector growth. For instance, many domestic organic waste treatment plants now process biogas slurry to meet local sewage acceptance standards, enabling discharge to municipal wastewater treatment plants for further purification.

(2) Concentrate Problems

After the implementation of garbage classification, the reduced volumes of garbage entering landfills, and incineration plants have correspondingly decreased leachate generation, consequently lowering concentrate production. Moreover, the separation of wet waste, recyclables and hazardous waste has significantly reduced organic content, heavy metals, and salinity in dry waste. These changes yield two transformative effects:

a. Membrane System Optimization: Improved water recovery rates with reduced concentrate volumes.

b. Concentrate Reuse Feasibility: Enables 100% concentrate recycling at incineration plants, eliminating this persistent leachate treatment challenge.

Additionally, evolving discharge standards are driving industry adoption of non-membrane advanced treatment, which avoids concentrate generation altogether. This paradigm shift resolves the central issue at its source.

(3) The promotion and application of the new process in the permeate industry

a. Application of Pre-denitrification Processes

With the implementation of garbage classification, many Chinese cities are constructing new kitchen waste treatment plants. After the anaerobic digestion, the treated kitchen waste becomes exceptionally high in ammonia nitrogen levels (empirical data from existing projects show concentrations exceeding 4,000mg/L). However, the front-end anaerobic process, which is aiming for maximum biogas production, yields digestate with relatively low COD content, failing to meet the C/N ratio required for efficient biological nitrogen removal. While carbon supplementation increases operational costs, these conditions are driving significant attention toward pre-denitrification processes.

Pre-denitrification processes contain many methods. Leachate from aging landfills have a severely imbalanced C/N ratio, while the organic content of fresh garbage after garbage classification is low. The combined leachate can not solve the problem of insufficient carbon sources. In terms of the improvement of the leachate treatment process for aging landfills, pre-denitrification processes are necessary.

b. Application of Short-Cut Nitrification-Denitrification and Anaerobic Ammonium Oxidation (Anammox) Processes

With the implementation of garbage classification, the leachate treatment industry urgently requires low-carbon or carbon-free nitrogen removal technologies. For high-ammonia kitchen waste biogas slurry (post-anaerobic digestion and de-watering), the adoption of short-cut nitrification-denitrification or anaerobic ammonium oxidation can effectively remove ammonia and total nitrogen, significantly reducing the load on downstream biological treatment, lowering operational costs, and improving treatment efficiency.

c. Application of Advanced Biological Nitrogen Removal Technologies

After garbage classification, many leachate treatment projects, especially those in kitchen waste treatment plants, now face a situation where COD compliance is relatively achievable, but total nitrogen removal remains a critical challenge. Operational data from similar projects show that conventional dual-stage A/O + MBR systems typically achieve effluent total nitrogen levels of 70-150mg/L, while municipal wastewater treatment plant acceptance standards impose stricter TN limits of 40-50 mg/L. Given the prohibitive costs of relying solely on reverse osmosis for total nitrogen removal, advanced biological nitrogen removal processes such as denitrification filters and deep-bed denitrification filters are gaining prominence, as they ensure total nitrogen compliance without generating concentrated waste streams.

d. Application of Non-Membrane Advanced Treatment Technologies

With the advancement of garbage classification, the treatment of biogas slurry from kitchen waste treatment plants will become a key focus in leachate management. Unlike waste incineration plants and landfills, kitchen waste facilities face significant challenges in handling secondary pollutants (e.g., concentrate) generated from leachate treatment. To meet discharge standards while avoiding concentrate production, non-membrane advanced treatment processes are increasingly favored. These technologies offer a sustainable alternative, eliminating the need for costly concentrate disposal and reducing operational burdens.

5. Conclusions

(1) With the active advancement of waste classification, the generation volume of landfill leachate will decrease.

(2) Waste classification significantly affects leachate quality - the C/N ratio imbalance in landfill leachate will become more severe, while heavy metal content will reduce.

(3) Waste classification will drive technical upgrades to existing leachate treatment processes at waste incineration plants and landfills, while treatment processes for biogas slurry from kitchen waste treatment plants require further optimization.

(4) Waste classification will promote changes in discharge standards for leachate treatment, making them better aligned with industry characteristics and development needs.

(5) New treatment technologies will be progressively adopted in leachate treatment as waste classification is implemented.