Product Category

- Wastewater Treatment Equipment

- -CDFU(Cyclonic Dissolved Gas Flotation Unit)

- -CDOF(Cyclonic Dissolved Ozone Flotation Unit)

- -Heterogeneous Catalyst

- -Micro-Bubbles Generation System

- -Oil-Water Separation Equipment

- -Filters

- Wastewater Treatment Process

- -Refinery Oily Wastewater Treatment

- -Tank Area and Oil Depot Water Treatment

- -Oilfield Reinjection Water Treatment

- -Fracturing Flowback Fluid Treatment

- Cases

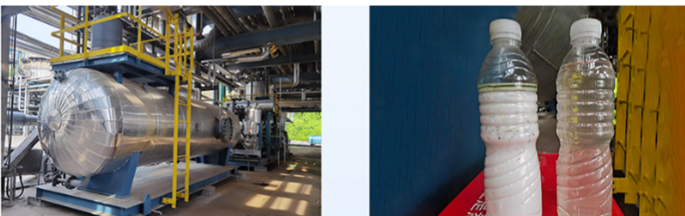

Emulsified Acidic Water Treatment in Coking Plant

Product Detail

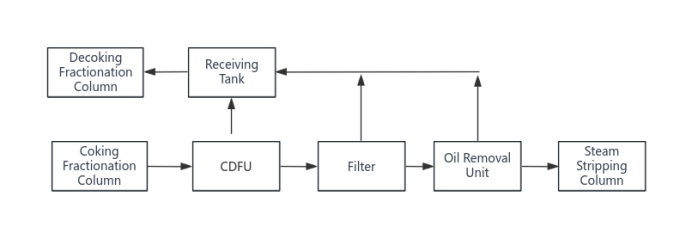

Process flow

Process Introduction

Petroleum and its products contain sulfur and nitrogen compounds. During processing steps such as atmospheric and vacuum distillation, catalytic cracking, delayed coking, and catalytic hydrogenation, these compounds undergo reactions including high-temperature pyrolysis, catalytic cracking, and hydrocracking, generating H₂S and NH₃-N that enter the product waste streams. When these waste streams undergo condensation dehydration or water washing treatment, they produce wastewater containing sulfur and ammonia, commonly known as sulfur-containing wastewater or acidic water.

Features

1. High content of coke powder with a small particle size distribution.

2. High oil content, small droplet size, and severe emulsification.

3. High levels of sulfur, ammonia nitrogen, and phenols.

4. Complex composition with significant fluctuations in content.

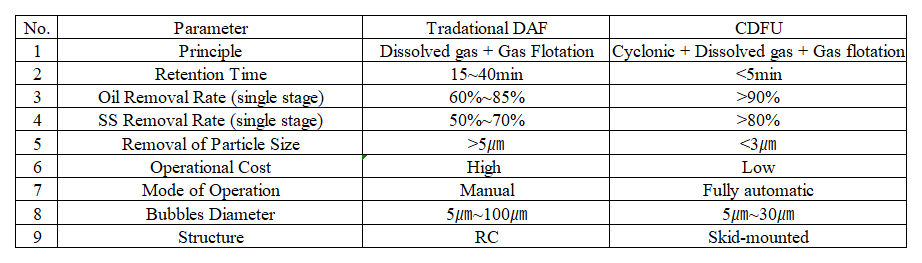

Utilizing CDFU (Cyclonic Dissolved Gas Flotation Unit) + Fine Filtration + KHC (High-Efficiency Coalescing Oil-Water Separator) as core technologies, this equipment achieves an emulsified oil removal precision of up to 0.1µm and an outlet oil content below 10ppm. This technology demonstrates feasibility, reliability, and significant environmental and economic benefits compared to traditional methods, positioning it at the forefront domestically.

Application Case