Product Category

- Wastewater Treatment Equipment

- -CDFU(Cyclonic Dissolved Gas Flotation Unit)

- -CDOF(Cyclonic Dissolved Ozone Flotation Unit)

- -Heterogeneous Catalyst

- -Micro-Bubbles Generation System

- -Oil-Water Separation Equipment

- -Filters

- Wastewater Treatment Process

- -Refinery Oily Wastewater Treatment

- -Tank Area and Oil Depot Water Treatment

- -Oilfield Reinjection Water Treatment

- -Fracturing Flowback Fluid Treatment

- Cases

Coking and Emulsified Acidic Water Treatment

Product Detail

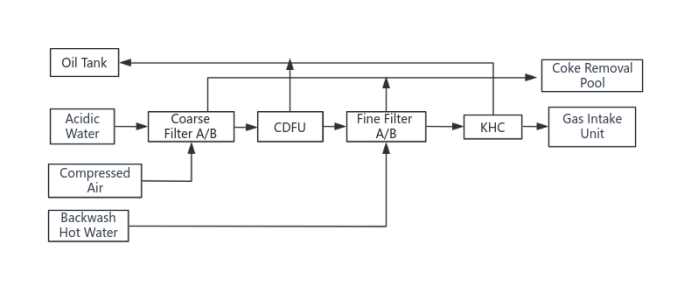

Process Flow

Highly emulsified coking acidic wastewater treatment has long been a challenge in the petroleum refining industry's wastewater treatment. In the acidic water of refining, the acidic water produced by coking has a high content of various components, and the types are particularly complex. The main characteristics include:

1. High coke powder content with a small particle size distribution;

2. High oil content, small droplet size, and severe emulsification;

3. High levels of sulfur, ammonia nitrogen, and phenols;

4. Complex composition with significant fluctuations in content.

Technological Advantages

1. The device operates without the need for chemical agents, thereby avoiding issues related to excessive chemical dosing and the generation of floating residues and oil sludge, fundamentally addressing the risk of secondary contamination.

2. Employing a pure physical treatment method, the device demonstrates consistent and effective emulsion breaking, efficiently separating emulsified oil and suspended solids from the wastewater, thus enhancing the treatment efficiency of the wastewater.

3. The recovered separated oil from the device exhibits high quality, low water content, and is suitable for reclamation, thereby conserving resources while generating economic benefits.

4. The device operates fully automated, in a sealed and pressurized manner, posing no safety or environmental risks, ensuring the safety of operating personnel.

5. Compact in footprint, the device boasts low operational costs.

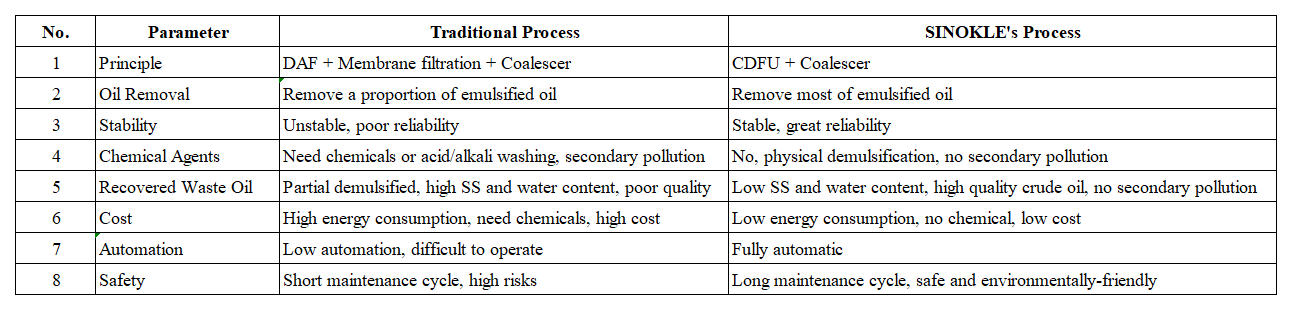

Technical Comparison

Application Case