Advanced Ozone Oxidation: The Future of Water Treatment

Taking ozone as the core oxidant, the advanced ozone oxidation process is an advanced water treatment technology designed to remove organic pollutants and microorganisms from water. This technology mainly relies on the strong oxidizing properties of ozone itself, which can destroy the molecular structure of organic substances and convert them into harmless small-molecule substances.

In actual water treatment processes, ozone can either react directly with pollutants or conduct indirect reactions by generating reactive oxidation media such as hydroxyl radicals (·OH), thereby achieving the dual effect of water purification.

Pic 1. Ozone preparation room in an oilfield

Compared with traditional treatment methods, the advanced ozone oxidation process demonstrates the following prominent advantages:

(1) Strong oxidation capacity: Ozone can effectively oxidize a wide range of organic and inorganic pollutants, especially targeting biologically refractory substances.

(2) Rapid reaction rate: In comparison with conventional chemical treatment methods, ozone reacts at a much faster speed, significantly shortening the treatment cycle.

(3) No secondary pollution risk: The main product of ozone decomposition in water is oxygen, with no harmful by-products left behind.

(4) Water quality improvement: Ozone treatment can effectively eliminate water color and odor, enhancing water transparency and drinking taste.

(5) High flexibility: Ozone treatment systems feature excellent adjustability, enabling flexible adaptation according to variations in water quality and treatment requirements.

(6) Reduced disinfection by-products: Compared with chlorine disinfection, ozone can significantly decrease the formation of disinfection by-products such as trihalomethanes.

With the continuous improvement of global environmental protection requirements and water safety standards, advanced ozone oxidation technology, characterized by its high efficiency, rapidity and environmental friendliness, boasts broad application prospects and development potential in fields such as drinking water treatment, industrial wastewater treatment and wastewater treatment plant effluent upgrading.

Despite its remarkable advantages, the practical promotion of this technology still faces such realistic challenges as low ozone utilization efficiency, high operating costs and substantial initial investment. To address these limitations, heterogeneous ozone catalytic technology has gradually attracted increasing attention as an innovative approach.

Heterogeneous ozone catalytic technology can improve ozone utilization efficiency, reduce treatment costs and accelerate reaction processes by adding catalysts. The presence of catalysts promotes the decomposition of ozone to generate more hydroxyl radicals (·OH), thereby enhancing the oxidation effect. The increased reaction rate means that ozone dosage and energy consumption are reduced, further saving operating costs. In addition, heterogeneous catalysts generally have good stability and a long service life, lowering the frequency of replacement and maintenance.

The independently developed KHC-F2001 silicon-aluminum-based (Si-Al) ozone catalyst by Sinokle is one of the key materials for improving reaction efficiency and achieving energy conservation and consumption reduction. This catalyst adopts a variety of transition metal oxides (including precious metals) as active components and employs a multi-stage precise temperature-controlled sintering process, which ensures high catalytic activity while enhancing stability. The unique pore-forming technology is applied in the roasting process, ultimately producing a silicon-aluminum-based catalyst with high strength, large specific surface area, excellent catalytic performance, acid and alkali corrosion resistance and easy recyclability. With outstanding performance in stability, selectivity and environmental friendliness, KHC-F2001 provides strong support for the sustainable development of the water treatment industry.

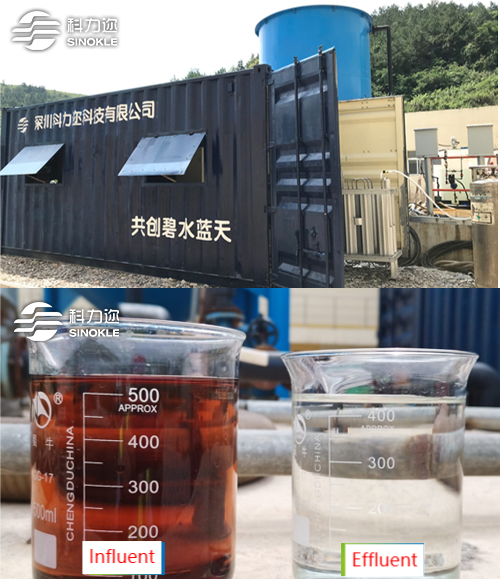

Sinokle integrated its core CDOF (Cyclonic Dissolved Ozone Flotation Unit) with its independently developed heterogeneous ozone catalyst, innovatively combining advanced ozone oxidation, hydrocyclone technology, and dissolved air flotation to achieve highly efficient, comprehensive treatment of various recalcitrant wastewaters. Within the CDOF system, micro-nano oxygen bubbles continuously clean and agitate the catalyst, enhancing contact and reaction efficiency. This not only improves the reaction efficiency between ozone and the catalyst but also prevents catalyst caking and clogging. Simultaneously, the microbubbles remove suspended solids, colloids, and oils, thereby reducing non-dissolved COD and minimizing ozone consumption.

As countries around the world continue to raise their requirements for environmental protection and water quality, the market demand for ozone catalysts in the water treatment field is constantly expanding. Especially in key links such as safe drinking water purification, industrial wastewater treatment and advanced purification of wastewater treatment plant effluent, ozone catalysts show considerable application prospects and market potential.