Beyond Traditional DAF: How CDFU Solves Oil-Water Separation Headaches

With the rapid development of urban construction, the discharge of industrial wastewater and domestic sewage has been on a steady rise, and the load on wastewater treatment facilities has been increasing steadily. In practical operation, traditional dissolved air flotation (DAF) processes often face several bottlenecks, such as large bubble size, significant fluctuation in treatment effect, high chemical dosage, large energy consumption, and increased subsequent solid waste disposal costs caused by a large amount of sludge produced. Implementing systematic technological transformation and introducing cutting-edge processes and equipment such as micro-nano bubble dissolved air flotation can effectively improve treatment efficiency, achieve energy conservation, consumption reduction and operation cost control.

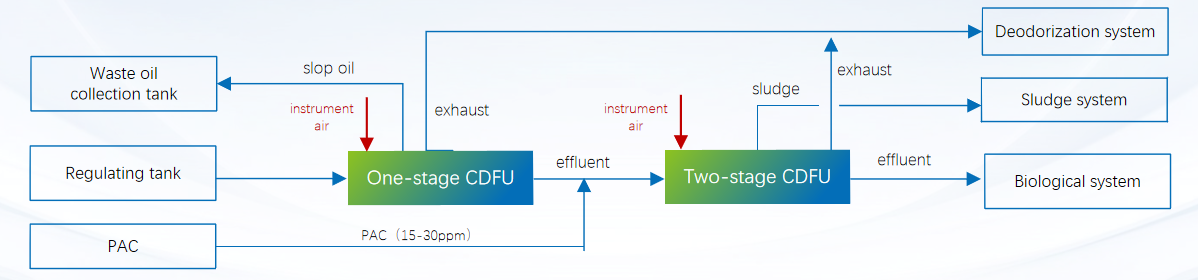

To address the urgent demand for upgrading the quality and efficiency of the dissolved air flotation unit in current wastewater treatment plants, we have launched a process upgrading solution centered on the CDFU (Cyclonic Dissolved Gas Flotation Unit) technology. Through the synergistic effect of two-stage CDFU units, this solution can efficiently realize oil-water separation and suspended solids (SS) removal with only a small amount of chemicals added, ensuring the effluent quality stably meets the standard. Committed to fully improving treatment efficiency, reducing energy and material consumption, and lowering operation and maintenance costs by virtue of advanced dissolved air flotation processes and equipment, this solution can thus adapt to the ever-growing total sewage treatment volume and increasingly stringent environmental protection standards.

As the core of this upgrading project, the CDFU (Cyclonic Dissolved Gas Flotation) Technology boasts multiple prominent advantages.

First, the primary CDFU adopts a purely physical demulsification and separation mechanism, featuring stable and reliable operation as well as high oil removal efficiency. It enables resource recovery of waste oil, avoids environmental pollution, simultaneously solves the disposal problem of oily sludge as hazardous waste, and brings considerable economic benefits.

Second, the secondary CDFU can achieve excellent removal effects of oil contaminants and suspended solids with the assistance of a small amount of Polyaluminum Chloride (PAC). The dosage of chemicals is significantly reduced, cutting the scum production by more than one-third, thereby decreasing the output of oily sludge (hazardous waste) and saving subsequent disposal costs.

In terms of environmental protection and safety, this technology also demonstrates outstanding performance. The system operates in a closed and pressurized mode, which can effectively prevent the escape of gases such as hydrogen sulfide, ensuring a safe and friendly operating environment. Meanwhile, the hydraulic retention time (HRT) of a single stage is less than 5 minutes, featuring a compact floor area, high overall automation level, simple maintenance and short construction period. It supports on-line renovation implementation, which significantly improves the operational efficiency and management level of sewage treatment plants.

In addition, the CDFU has good shock resistance and stable operation performance. Even when the influent water quality fluctuates greatly, the system can still maintain stable and reliable treatment effects. This characteristic enables it to exhibit stronger adaptability and operational flexibility when facing complex and variable sewage water quality.