Revolutionizing Acidic Wastewater Treatment: Sinokle’s KHC Separator Delivers Extraordinary Oil Removal Efficiency

Overview of Acidic Wastewater

In petroleum and its derivatives, sulfides and nitrides are commonly present. Through processing stages such as atmospheric and vacuum distillation, catalytic cracking, delayed coking, and hydroprocessing, these compounds undergo high-temperature cracking, catalytic conversion, and hydrocracking reactions, generating hydrogen sulfide (H2S) and ammonia nitrogen, which then enter the product stream. When this product stream undergoes condensation dehydration or water washing processes, wastewater containing sulfur and ammonia is formed, typically referred to as acidic water or sour water.

In a petrochemical water project, the acidic wastewater exhibited characteristics of high oil content and severe emulsification. This condition not only posed operational risks to downstream stripping units and sulfur recovery units, such as causing packing blockages and temperature excursions, but also created an impact on the subsequent wastewater treatment plant, affecting the achievement of final discharge standards. Additionally, a significant amount of high-quality light oil with recovery value was not effectively collected, resulting in economic losses. Therefore, effective treatment of this wastewater was imperative to eliminate production and environmental hazards, recover light oil resources, and achieve dual improvements in both environmental and economic benefits.

Sinokle's Acidic Wastewater Treatment Solution

Addressing the water quality characteristics of this project, Sinokle formulated a scientific acidic wastewater treatment plan and successfully applied its independently developed KHC Coalescing Oil-Water Separator. Test results demonstrated the equipment's exceptional performance in demulsification and oil removal. After treatment, the oil content in the water was reduced to below 50 mg/L (after excluding phenolic interference, the actual oil content was below 10 mg/L). Concurrently, the separated oil phase featured low water content and high quality.

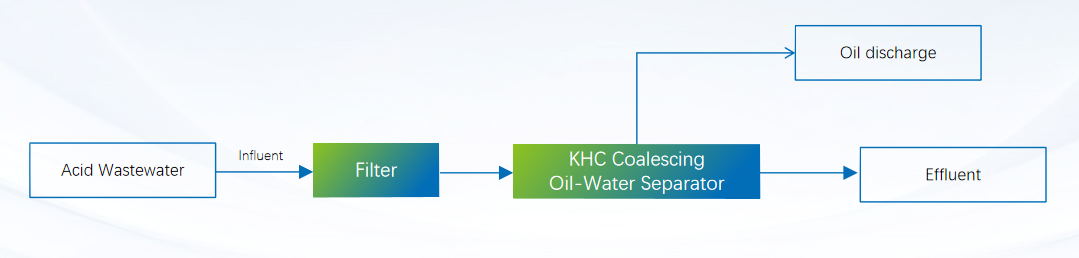

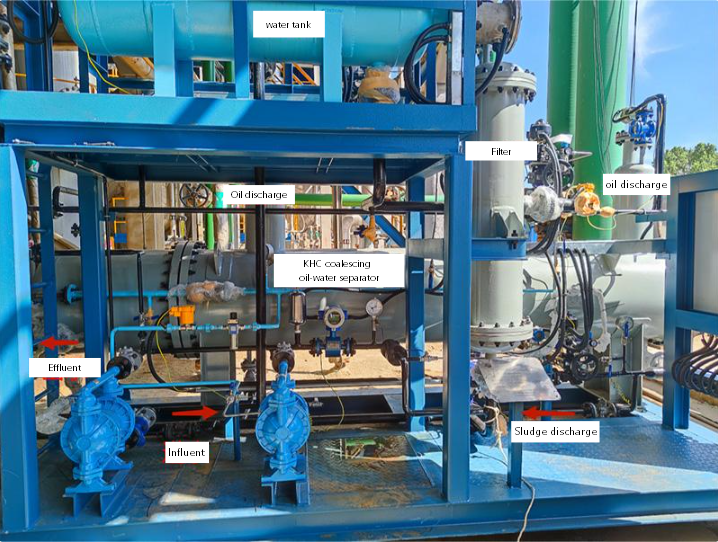

Brief Introduction to Sinokle's Acidic Wastewater Treatment Process

Under self-pressure, the acidic wastewater first passes through a filter to remove impurities, and then enters the KHC High-Efficiency Coalescing Oil-Water Separator. Within this unit, emulsified oil droplets rapidly demulsify and coalesce into larger droplets under the combined action of coalescing packing and coalescing media. These larger droplets rise to the surface and enter the oil collection zone for discharge, while the separated clean water flows out from the bottom of the unit.

At the treatment site, three water samples were collected from the unit's inlet, the KHC separator's oil outlet, and the water outlet, respectively, for analysis of their oil content and water content. The test data from five groups of samples indicated that after treatment by the KHC separator, the oil content in the effluent was stably maintained between 15 mg/L and 35 mg/L, with an oil removal efficiency of up to 99%. The treatment effect was significant, fully meeting the relevant standard of oil content ≤ 50 mg/L.

Further testing confirmed that after treatment process, the actual oil content in the acidic wastewater was only 7.91 mg/L when excluding phenolic interference, which is significantly lower than the specified discharge limit of 50 mg/L.

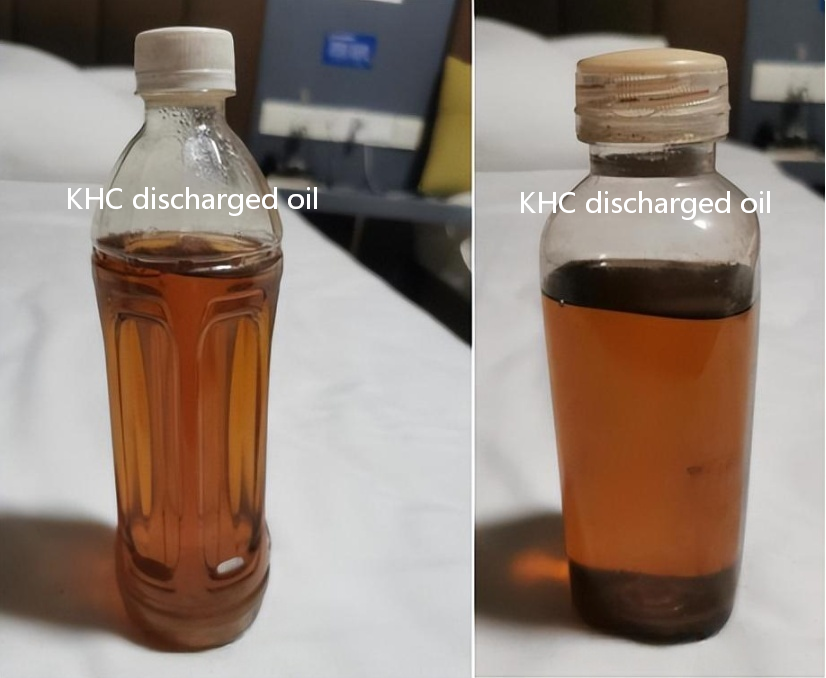

In addition, water content testing of the oil recovered by the coalescing oil removal unit showed results of 1.42% and 0.54%, indicating that the recovered oil is of high quality with extremely low water content.

The on-site effluent test data fully demonstrates that the KHC Coalescing Oil-Water Separator developed by Sinokle possesses excellent demulsification and oil removal performance in treating acidic wastewater. The effluent oil content is below 50 mg/L (less than 10 mg/L after excluding phenolic interference), and the recovered oil phase has low water content and high quality.

Sinokle's innovative demulsification and oil removal process, with the KHC as its core, can effectively address the issues of high emulsification and high oil content in acidic wastewater, mitigating their adverse effects on the operation and product quality of downstream sections such as stripping and sulfur recovery. While ensuring effluent water quality, reducing the subsequent wastewater treatment load, and improving the discharge compliance rate, this solution achieves efficient recovery of light oil, yielding significant economic and environmental benefits.