Breaking Through Ternary Precursor Wastewater Dilemma: Sinokle’s CDOF Technology Leads Green Innovation

Ternary Precursor: A Critical Material in the New Energy Industry Chain

The ternary precursor is a core raw material in the new energy industry chain, and its quality directly impacts the performance of end products. The wastewater from ternary precursor production often contains significant amounts of oils and Total Organic Carbon (TOC), posing a severe challenge for subsequent processing stages.

Conventional Treatment Processes for Ternary Precursor Wastewater

Currently widely adopted methods, such as activated carbon and resin adsorption, can partially remove impurities. However, they generally suffer from high costs, complex processes, and the generation of hazardous waste. These limitations mean they are increasingly unable to meet the demands of modern industrial development. The specific issues include:

High Costs: Due to the unique properties of the product solution, the use of coconut shell activated carbon and specialized resins is necessary, leading to elevated costs.

Hazardous Waste Disposal: Once saturated, the activated carbon becomes hazardous waste requiring off-site disposal, which increases operational costs.

Operational Complexity: Activated carbon needs frequent replacement, typically every two days, necessitating constant on-site monitoring and manual intervention, which is cumbersome.

Safety Risks: Ethanol is required during the resin regeneration process, imposing high safety requirements on-site and introducing certain risks.

Sinokle's Innovative Solution

To address these challenges, Sinokle has developed a novel deoiling and purification process for ternary precursor wastewater, based on its proprietary patent technology–the Cyclonic Dissolved Ozone (CDOF) Integrated System. This system integrates multiple advanced technologies, including ozone catalytic oxidation, hydraulic cyclone separation, and dissolved air flotation (DAF) for oil removal, complemented by Sinokle's independently developed modified heterogeneous ozone catalyst. This catalyst exhibits exceptional adsorption and catalytic oxidation capabilities for oils and TOC. It enables highly efficient oil removal and TOC reduction without altering the solution's ionic composition or compromising its purity.

Synergistic Multi-Technology Integration: CDOF technology uniquely integrates ozone catalytic oxidation, hydraulic cyclone separation, and dissolved air flotation (DAF) for oil removal into a single system. This innovative design is patented in China and internationally leading.

High Efficiency & Low Consumption: It achieves high ozone utilization efficiency with low energy consumption. The operational cost is only 1/3 to 1/2 that of activated carbon or resin adsorption methods. Furthermore, it generates no hazardous waste, making it environmentally friendly.

No Secondary Pollution: The treatment process requires no addition of chemical agents, ensuring no adverse impact on subsequent processing steps.

Rapid Processing Rate: Features a short hydraulic retention time and a compact footprint, making it suitable for production requirements of all scales.

Safety & Environmental Friendliness: Operates in a closed, pressurized system, eliminating ozone leakage. It is safe, environmentally friendly, and does not interfere with on-site operations.

Fully Automated Operation: Equipped with an intelligent control system that allows for remote operation guidance. It is unattended, significantly reducing labor costs.

Acid-Resistant Catalyst: Utilizes a new type of acid-resistant catalyst that performs effectively under acidic conditions without causing metal contamination.

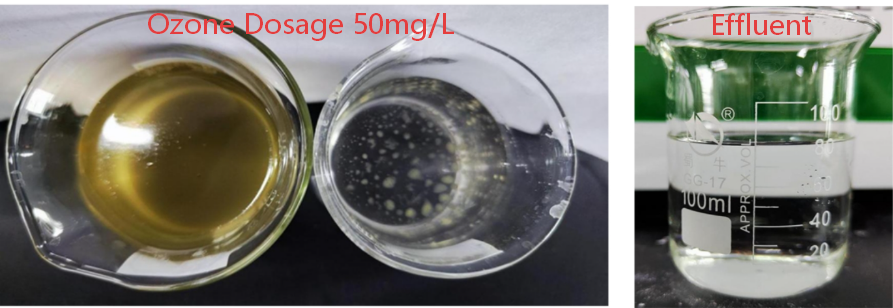

Highly Effective Removal: Capable of reducing oil content to below 2 ppm (including dissolved oil) and achieving a TOC removal rate of over 60%, thereby significantly improving the quality of the product solution.

Experimental Results and Comprehensive Advantages

Experimental results demonstrate that the CDOF process can stably control the oil content of the feed material to below 2 ppm, with the TOC removal efficiency also exceeding 60%.

Compared with traditional activated carbon and resin adsorption processes, CDOF technology offers numerous advantages

Superior Treatment Efficacy: It delivers excellent treatment results, with particularly remarkable performance in TOC reduction.

Reduced Waste Generation: CDOF technology eliminates the need for frequent catalyst replacement, significantly reducing the volume of hazardous waste generated and thus saving on disposal costs.

Simplified and Reliable Operation: The technology employs a fully automated, closed-loop operation mode, ensuring simple operation and reliable performance without causing secondary environmental pollution.

High Efficiency and Energy Savings: Characterized by high ozone utilization efficiency and low energy consumption, its operational cost is only 1/3 to 1/2 that of activated carbon or resin adsorption.

Enhanced Safety and Environmental Protection: Featuring closed, pressurized operation, it eliminates the risk of ozone leakage, thereby ensuring the safety and environmental friendliness of on-site operations.

With its exceptional purification performance and multiple process advantages, CDOF technology has established itself as the preferred solution for deoiling and TOC control in ternary precursor wastewater. This technology not only effectively enhances the quality of effluent but also infuses new momentum into the green and sustainable development of the new energy industry.