Treatment of Oily Wastewater in Oil Depot of Thermal Power Plants

During the operation of thermal power plants, the oily wastewater generated in the oil depot is a difficult challenge in environmental governance. Such wastewater mainly comes from links such as fuel oil tank cleaning, leakage flushing of oil pumps and pipelines, contains pollutants such as fuel oil residues and lubricating oil, and has characteristics including severe emulsification, small oil droplet size and complex composition.

Challenges Faced by Traditional Treatment Technologies

The traditional process of "oil separator tank + dissolved air flotation (DAF) tank + filtration" has obvious limitations: it cannot effectively remove emulsified oil, has poor shock resistance and insufficient effluent stability, and also features a large footprint and high operating costs. Especially for wastewater where the specific gravity of oil and water is close, gravity separation alone makes it difficult to meet the current environmental protection standards.

Sinokle's Innovative Solution

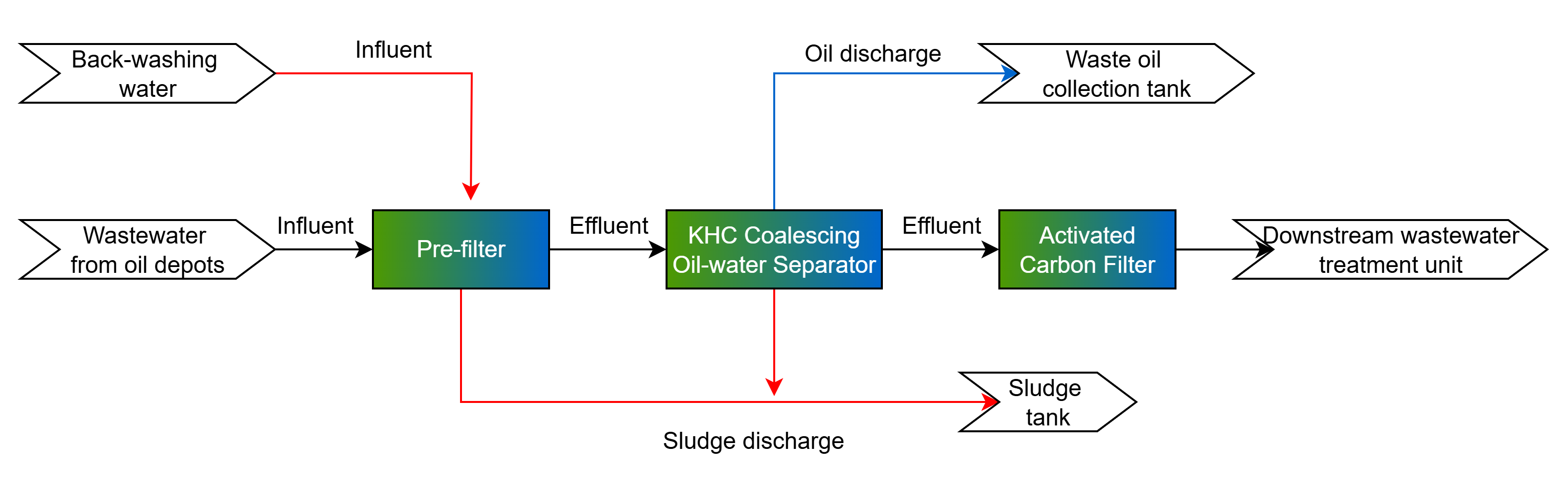

Targeting the characteristics of oily wastewater in oil depot, Sinokle has developed a integrated technical solution of "prefilter + KHC coalescing oil-water separator". This solution adopts the physical principle of demulsification and separation, and achieves efficient oil-water separation through special coalescing fiber materials and optimized internal component design.

Process Flow

Wastewater enters the prefilter from the collection/buffer tank for preliminary treatment, and then flows into the KHC coalescing oil-water separator. Inside the separator, super lipophilic and hydrophobic materials are used to achieve rapid coalescence and separation of oil droplets. The treated effluent can either be directly discharged up to standard or sent to downstream treatment units.

Distinct Technical Advantages

This solution boasts multiple advantages:

- •Purely physical demulsification eliminates the need for chemical agents, avoiding secondary pollution from the source;

- •Oil removal efficiency reaches over 95%, capable of treating emulsified oil with particle sizes of 0.1μm and above;

- •Fully automated and enclosed operation eliminate safety and environmental risks;

- •Skid-mounted design requires a small footprint, only 1/5 of that of traditional processes.

Validation through Practical Application

A wastewater treatment project for the light oil depot of a combined heat and power (CHP) plant in Shaanxi Province was put into operation in September 2022, with a treatment capacity of 120 m³/d. The combined process of prefilter + KHC coalescing oil-water separator was adopted. The influent oil content was 200 mg/L and suspended solids (SS) were 100 mg/L; after treatment, the effluent oil content was reduced to below 5 mg/L, SS ≤ 5 mg/L, and the oil removal rate exceeded 97%.

The project covers an area of only 2.6m (L)×1.5m (W)×2m (H), demonstrating the advantages of compact design. The equipment operates stably with strong shock resistance—even when the influent water quality fluctuates significantly, it can still maintain stable effluent quality and meet the standard, providing a reliable guarantee for the plant’s compliance with environmental regulations during operation.

Prospects

With the increasingly stringent environmental protection requirements, Sinokle's oily wastewater treatment solution for oil depots, featuring high efficiency, stability and environmental friendliness, boasts broad application prospects in the power industry. This technology not only meets current discharge standards but also provides technical support for the green transformation and sustainable development of thermal power plants. Through continuous technological innovation and engineering optimization, the solution is expected to further reduce costs and improve efficiency, offering an economical and reliable option for oily wastewater treatment to more power enterprises and helping the industry achieve the dual goals of environmental protection and economic benefits.