Green Revolution: Chemical-Free Oil Removal Technology

In today's era of increasingly stringent environmental regulations, chemical-free oil removal technology has emerged as a key technical direction in industrial wastewater treatment. The CDFU (Cyclonic Dissolved Gas Flotation technology) developed by Sinokle has achieved a breakthrough in this field with its innovative pure physical demulsification process.

Technical Principle: Innovative Breakthrough via Multi-Technology Integration

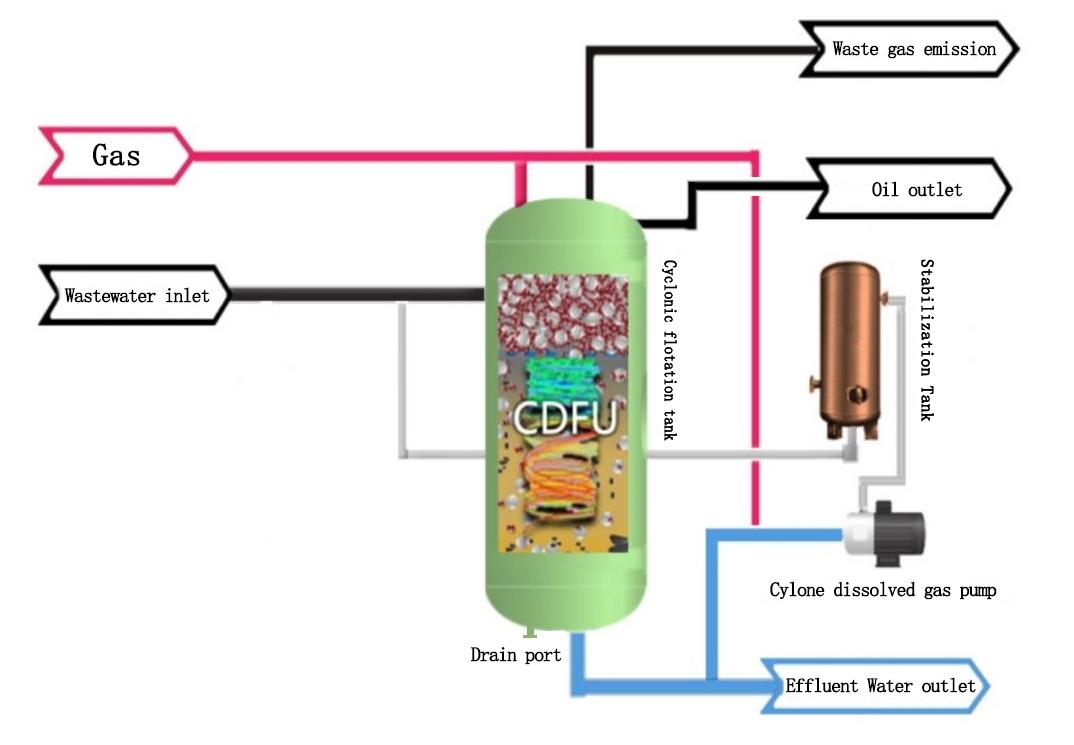

The CDFU ingeniously integrates centrifugal separation technology, dissolved air flotation separation technology, and micro-bubble generation technology, forming a highly efficient integrated treatment system. Through a special structural design, the technology generates ultra-fine bubbles with a diameter of only 5-30 microns. These bubbles feature uniform dispersion and high adsorption efficiency, enabling effective adhesion to oil droplets and suspended solids (SS) in wastewater.

Compared with traditional chemical methods, the core advantage of CDFU technology lies in its pure physical demulsification mechanism. During operation, the oily wastewater to be treated is mixed with dissolved air water (which produces a large number of ultra-fine bubbles via a releaser), then tangentially enters the cyclonic separation zone. Under strong centrifugal force, heavy SS are rapidly separated. The mixture then enters the flotation separation zone, where dispersed oil, emulsified oil, and suspended solids are quickly adhered to micro-bubbles, demulsified, agglomerated, and floated to the surface for discharge.

Performance Advantages: Distinctive Features of High Efficiency and Environmental Friendliness

CDFU demonstrates outstanding treatment performance: the single-stage oil removal efficiency exceeds 90%, the suspended solids removal rate is over 85%, and the oil content in the effluent can be stably controlled below 5 mg/L. More impressively, its retention time is only 1-5 minutes, with efficiency 3-8 times that of traditional DAF processes.

The environmental benefits of this technology are particularly prominent. Since no chemical agents are added at all, the generation of oily sludge is fundamentally eliminated, avoiding the risk of secondary pollution. Meanwhile, the recovered waste oil has refining value, achieving a win-win situation of environmental and economic benefits. Additionally, the fully enclosed pressurized operation design ensures no odor leakage, realizing truly green treatment.

Application Case

In a black water treatment project for a refinery enterprise in Xinjiang, the combined process of "Coalescing Pressure Oil Separator + CDFU" was adopted. This all-physical method achieves efficient demulsification and oil removal without adding chemical agents, generates no sludge (zero secondary pollution), and enables the recovery and refining of waste oil, yielding considerable economic benefits.

Development Prospects

The skid-mounted design of CDFU technology reduces its floor space to only 1/3 of traditional equipment, making it particularly suitable for space-constrained scenarios such as offshore platforms. The modular structure ensures easy installation and significantly shortens the construction period. The intelligent operation system integrated with the Internet of Things (IoT) and AI supports remote monitoring and unmanned operation, drastically reducing labor costs.

As global environmental standards continue to rise, physical oil removal technologies represented by Sinokle's CDFU technology are being widely applied in fields such as petroleum refining, electric power, and municipal wastewater treatment. Its pure physical, chemical-free technical characteristics not only meet current environmental requirements but also provide a reliable path for the sustainable development of industrial wastewater treatment.