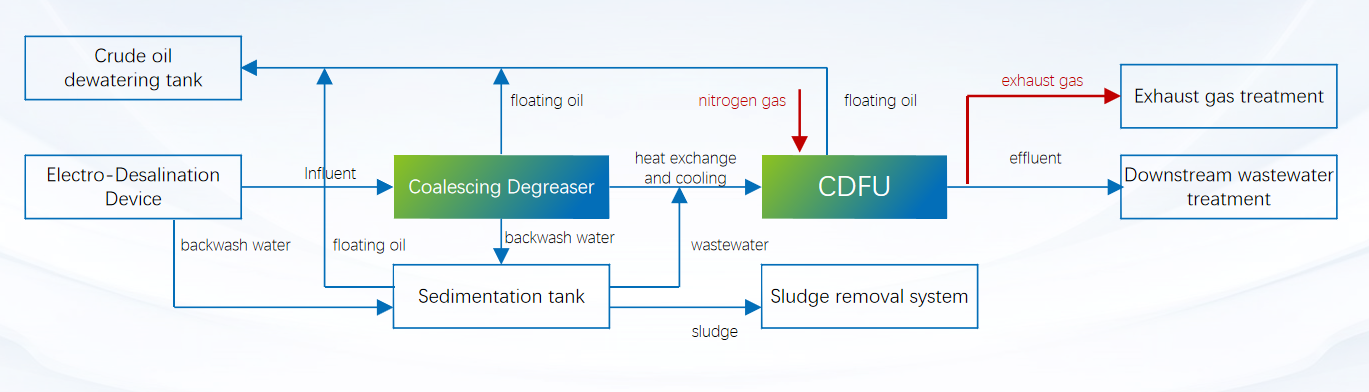

The process flow of oil refining wastewater treatment

Refinery wastewater has long been a key challenge in industrial wastewater treatment due to its high oil content, complex composition, and abundance of recalcitrant organic pollutants. Sinokle Technology Co., Ltd. has developed an efficient, environmentally friendly, and resource-recovering refinery wastewater treatment process system based on its proprietary core technologies, including CDFU (Cyclonic Dissolved Gas Flotation Unit) and CDOF (Cyclonic Dissolved Ozone Flotation Unit).

1. Core Process Flow

Sinokle's refinery wastewater treatment process consists primarily of two stages: pretreatment and advanced oil removal.

Pretreatment Stage: A coalescing pressure oil separator is employed for coarse granulation and separation, rapidly removing dispersed oil droplets larger than 30 µm with an oil removal efficiency exceeding 90%. This unit integrates cyclonic pre-separation and an automatic sand-flushing system, offering strong anti-clogging performance and excellent resilience to shock loads from high-oil-content wastewater.

Advanced Oil Removal Stage: The core equipment is the CDFU (Cyclonic Dissolved Flotation Unit), which generates ultrafine bubbles sized 5–30 µm to efficiently separate emulsified oil. Utilizing a purely physical demulsification mechanism that requires no chemical additives, the system consistently achieves effluent oil concentrations below 10 ppm and removes over 85% of suspended solids. The CDFU operates fully enclosed under pressure, with a single-stage hydraulic retention time of less than 5 minutes and a footprint only one-third that of conventional dissolved air flotation systems.

Figure 1. Process flow of electro desalination wastewater

Figure 1. Process flow of electro desalination wastewater

2. Technical Advantages

Green and Resource-Oriented: The entire process relies solely on physical separation technologies, enabling high-quality oil recovery that can be directly returned to refinery feedstock. Critically, the system generates no oily sludge (hazardous waste), thereby achieving dual objectives: effective pollution control and valuable resource recovery.

High Efficiency and Robust Stability: The CDFU technology achieves over 98% removal efficiency for suspended solids larger than 2 µm and demonstrates exceptional resilience to hydraulic shock loads, accommodating flow fluctuations of up to ±50%. In a real-world application, the system successfully treated influent with oil concentrations below 2,000 ppm and consistently delivered effluent with oil levels under 10 ppm—demonstrating outstanding oil removal performance.

Intelligent and Compact Design: Modular skid-mounted configuration reduces footprint by 30–50% and enables rapid, online deployment. Fully automated controls allow for unattended operation, cutting operational and maintenance costs by more than 50%.

3. Practical Cases

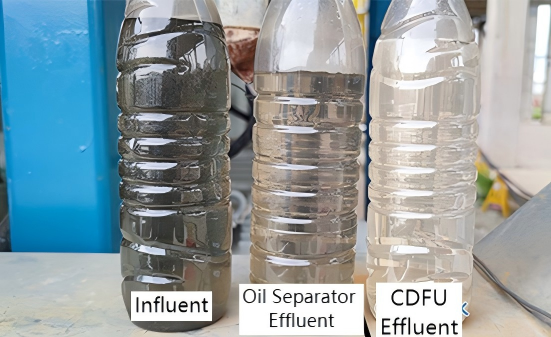

In a electric desalination wastewater treatment project in Sinopec Cangzhou branch, Sinokle adopted "Coalescing Pressure Degreaser + CDFU" integrated process, achieving a treatment capacity of 50m³/h.The oil concentration in the effluent was reduced from >20,000 mg/L to 35 mg/L, with the entire system occupying a compact footprint of just 16.5 m × 2.2 m.

Figure 2. Project in Sinopec Cangzhou branch

For oil depot dewatering wastewater treatment, Sinokle's process can reduce the influent oil concentration from <3,000 mg/L to an effluent level of <5 mg/L, and decrease suspended solids from <300 mg/L to ≤20 mg/L. This effectively resolves the long-standing challenge of oil depot wastewater discharge compliance.

Figure 3. Project for oil depot dewatering wastewater

4. Development Prospects

As environmental regulations become increasingly stringent, Sinokle's purely physical separation technology offers refineries a viable pathway toward green transformation. Its modular and intelligent design is especially well-suited for both retrofits of existing facilities and new plant construction. Beyond ensuring compliance with discharge standards, the process generates economic value by recovering reusable oil from wastewater.

Looking ahead, this technology holds strong potential for broader adoption across the refining and petrochemical industry, providing robust technical support for the sector's sustainable development.