Innovation in Oilfield Oily Wastewater Treatment Technology: Comprehensive Solutions from Sinokle

During the oilfield extraction process, the treatment of oily wastewater has always been a significant challenge faced by the industry. With increasingly stringent environmental protection requirements, traditional treatment technologies have struggled to meet current discharge and reuse standards. Sinokle, leveraging its innovative core technologies such as the CDFU Cyclonic Dissolved Gas Flotation unit, offers a groundbreaking solution for the treatment of oily wastewater in oilfields.

Ⅰ.Core Technology: Cyclonic Dissolved Gas Flotation Unit (CDFU)

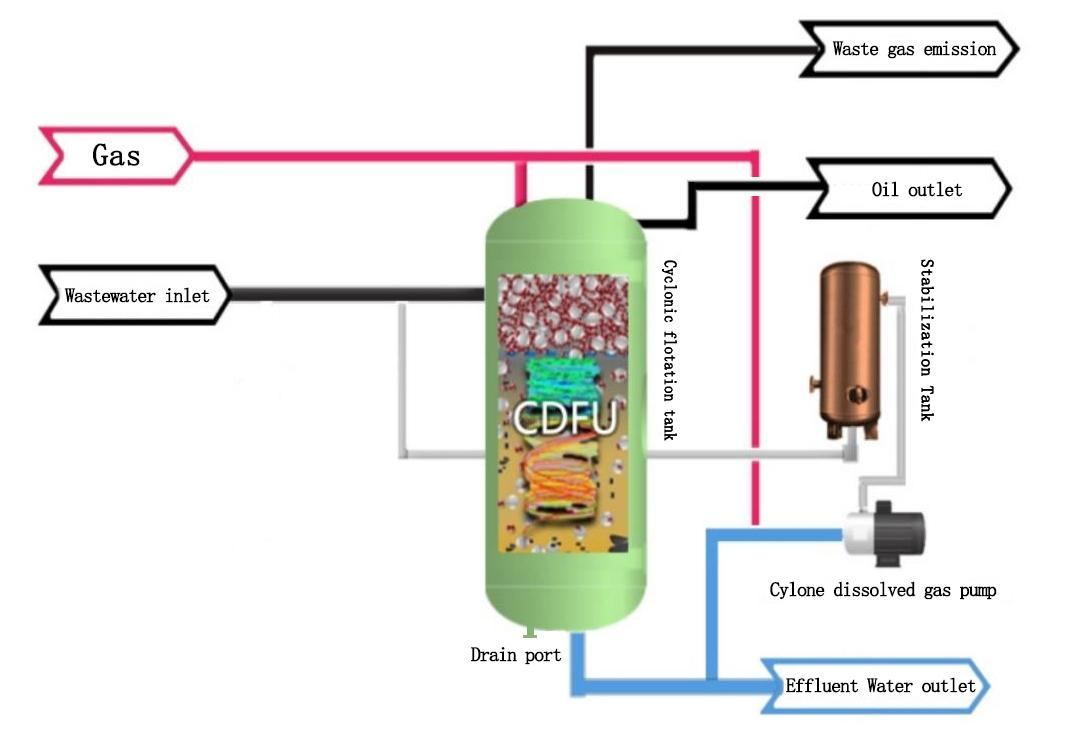

CDFU, independently developed by Sinokle, integrates cyclonic centrifugal separation, dissolved gas flotation, and ultra-fine bubble generation technology into a single process, forming a unique treatment method. By generating ultra-micro bubbles with diameters of 5-30 micrometers, the unit significantly enhances oil-water separation efficiency, achieving a single-stage oil removal rate of over 90% and a suspended solids removal rate exceeding 85%.

CDFU Working Principle & Micro-bubbles ffect drawing

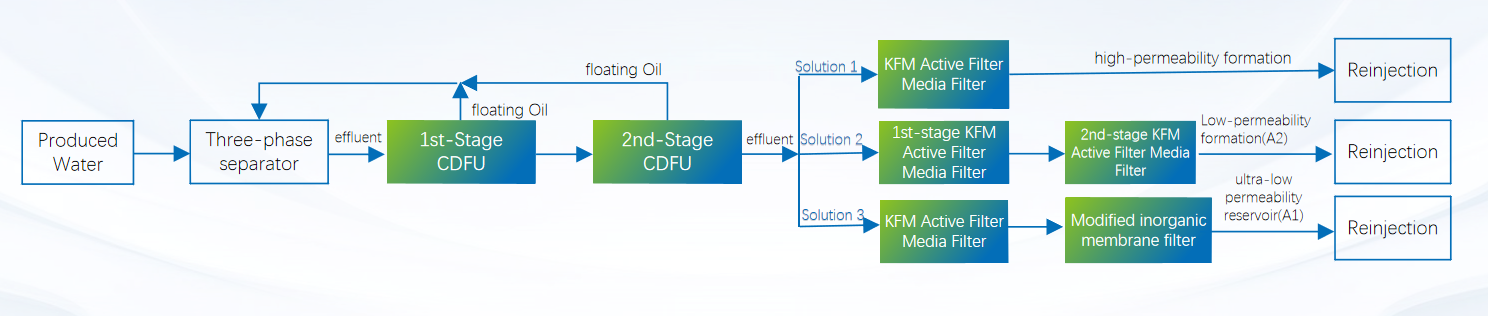

In practical applications, the CDFU unit has demonstrated significant advantages. Taking the produced water treatment project at an oilfield in Congo, Africa, as an example, the influent oil content was as high as 3,825 mg/L. After two-stage CDFU treatment, the oil content was reduced to 27.5 mg/L. Following further advanced treatment with a KFM filter, the final effluent oil content was reduced to only 4.1 mg/L. This treatment outcome fully meets the standards required for water reinjection into high-permeability formations.

Ⅱ.Innovative Process Combination

Sinokle has developed a variety of process combination solutions tailored to the specific water characteristics of different oilfields. For conventional produced water, the “Two-stage CDFU + KFM filter” process is adopted. For fracturing flowback fluid, the “CDFU + CDOF” process is employed.

These processes all features distinct technical characteristics:

1. The treatment retention time is only 1-5 minutes, much shorter than traditional flotation processes.

2. Purely physical demulsification is achieved without the need for chemical additives, eliminating the generation of sludge.

3. The equipment operates fully enclosed under pressure, effectively preventing oil and gas leakage.

4. The skid-mounted design reduces the footprint (1/3 of traditional equipment), making it particularly suitable for space-constrained scenarios such as offshore platforms.

Ⅲ.Intelligent Operation

Sinokle's treatment system integrates IoT and AI technologies to achieve fully automated intelligent operation. The system can monitor water quality parameters in real-time, automatically adjust operational status, and support remote control and unmanned operation. This intelligent design not only reduces labor costs but also ensures the stability and reliability of the treatment process.

In the produced water treatment project at Xinjiang Oilfield, the “CDFU+KFM” process achieved a treatment capacity of 360 m³/d. The system has been operating stably for many years, with effluent quality consistently meeting standards. Successful cases with similar treatment process have been validated in other projects, including the CNOOC Weizhou produced water treatment project, the Yanchang Group oilfield produced water treatment, and the Congo oilfield produced water treatment project.

Project of Oilfield Produced Water in Congo

Ⅳ.Economic Benefits

Sinokle's solutions deliver significant economic benefits while ensuring treatment effectiveness. Compared to conventional processes, they reduce operating costs by 20-30% and lower the energy consumption by 40%. With up to a 15-year lifespan and long maintenance intervals, these solutions substantially reduce the whole life cycle cost.

Ⅴ.Future Expectations

Driven by increasingly stringent environmental standards, Sinokle continues to advance technological innovation. The company has now obtained more than 30 patents, including 7 invention patents and 1 PCT international patent. In the field of oily wastewater treatment, Sinokle is driving the industry toward greater efficiency and environmental sustainability.

Sinokle's oily wastewater treatment solutions not only address current technical challenges faced by the industry but also provide reliable support for the sustainable development of oilfields. Through its innovative technologies and successful practical applications, Sinokle is creating a new benchmark for global oilfield environmental management.