Revolutionary Process Solves the Problem of Acidic Wastewater in the Refining Industry

New Treatment Process Tackles the Challenge of Acidic Wastewater in the Refinery Industry

During the production process of refining, the treatment of acidic water has always been a persistent challenge. This type of wastewater not only contains high concentrations of hazardous substances but also possesses specific characteristics that make the treatment process particularly difficult. However, with the development of technology, new treatment processes have emerged, providing potential solutions to these issues.

Sources and Characteristics of Acidic Wastewater

Acidic water primarily originates from the top of the vacuum distillation tower in refineries. During the refining process, a large amount of wastewater is generated. Among these waste streams, acidic water is particularly challenging because of its high concentration of hazardous substances such as sulfides, ammonia nitrogen, phenols, and volatile compounds. These substances are not only highly toxic but also prone to accumulation, posing significant threats to the environment. In addition, the pH value of acidic water is normally low, which further complicates its treatment.

Challenges of Treatment

traditional process for acidic wastewater treatment has many drawbacks or limitations. For instance, while gravity sedimentation is simple to implement, the settling time is long, and the method has limited separation efficiency. Chemical precipitation demands a significant amount of chemical agent, leading not only to high treatment costs but also to the potential for secondary pollution. Therefore, how to efficiently and economically handle acidic water has always been a challenge for the refining industry.

SINOKLE's Innovative Process: Centred on CDFU (Cyclonic Dissolved Gas Flotation Unit) + KHC (Coalescing Oil-Water Separator)

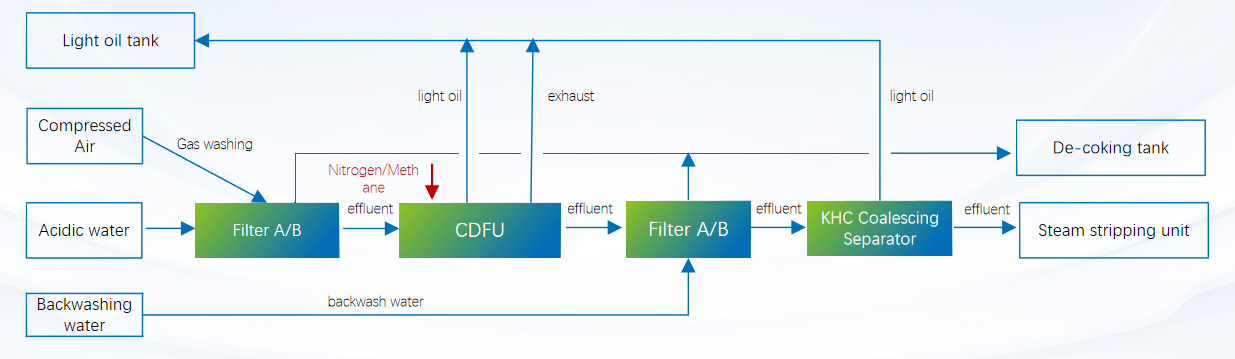

To address the challenges of acidic wastewater treatment in the refining industry, SINOKLE has introduced a new process centred around the CDFU and KHC as its core components. This process primarily utilize CDFU for wastewater pretreatment. Through leveraging the principles of cyclonic flow and dissolved air flotation (DAF), it effectively removes oil, suspended solids (SS) and dissolved organic matter from the wastewater. Subsequently, the wastewater enters the KHC Coalescing Oil-Water Separator, where specialized coalescing media cause small oil droplets to coalesce into larger ones, enabling further oil-water separation.

Process Flow of Treating Refinery Acidic Wastewater

The working principle of the CDFU unit is utilizing cyclonic action to rapidly collide and adhere SS and oil particles in the wastewater with micro-bubbles generated by dissolved gas. This forms large particles that rise to the surface, achieving solid-liquid separation. The KHC unit leverages the oleophilic and hydrophobic properties of the coalescing media to aggregate tiny oil droplets in the wastewater into larger ones, which then settle down under gravity, enabling highly efficient oil-water separation.

Features of New Process

SINOKLE's innovative process for treating refinery acidic wastewater possesses the following key features:

1. It achieves highly efficient oil-water separation with high removal rates and stable effluent quality.

2. The process does not require large quantities of chemicals, avoiding secondary pollution and reducing treatment costs.

3. It offers advantages such as a compact footprint, high automation, and reliable operation.

Case Study: Treatment of Highly Emulsified Acidic Wastewater in a Refinery Project

These features make the new process for treating coking acidic wastewater have of broad application prospect. To sum up, SINOKLE's process represents a new approach for treating acidic refinery wastewater, characterized by high efficiency, environmental benefits, and cost-effectiveness.