New Treatment Process for Oilfield Produced Water: The Integration of CDFU and KFM technology

In the field of oilfield produced water, SINOKLE's CDFU(Cyclonic Dissolved Gas Flotation Unit) and KFM (Activated Media Filter) can be integrated to form an efficient and physical treatment process. The process is designed to handle the high oil content, high suspended solids, and complex water quality of oilfield produced water, achieving comprehensive treatment from coarse separation to in-depth purification, making it suitable for re-injection or discharge requirements.

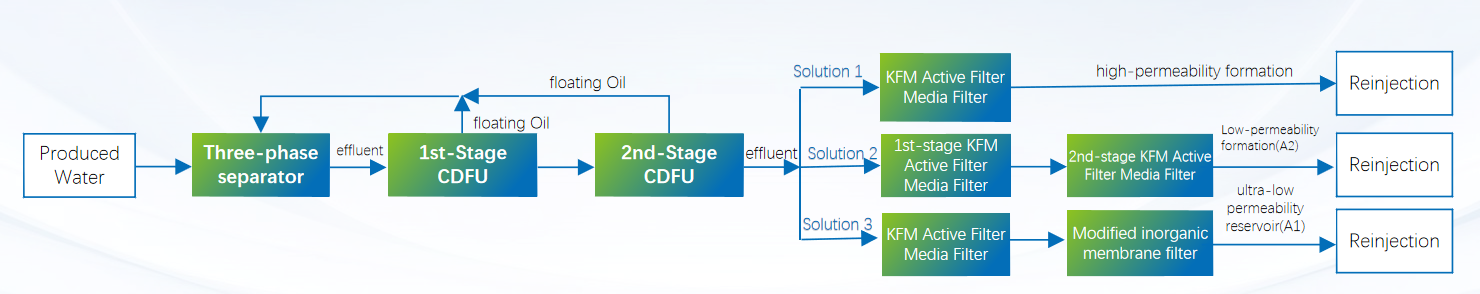

New Treatment Process

1. First-stage Treatment: Cyclonic Dissolved Gas Flotation Unit (CDFU)

Produced water mixes with dissolved gas waster and enters the CDFU unit. Under the combined action of cyclonic centrifugal force and ultrafine bubbles (D50 ≈ 25 µm), oil droplets and suspended solids rapidly collide, adhere, and forms floating scum that rise to the surface for removal. The treatment process take only 1-3 minutes, achieving a single-stage oil removal efficiency f >90% and emulsified oil removal f >90%l, all without the need for chemicals.

2. Second-stage KFM Activated Media Filter

The effluent from the CDFU (oil content ≤30 ppm, SS < 30mg/L) enters the KFM filter. Utilizing the adsorption and filtration capabilities of the activated silicate filter media (featuring a negatively charged surface and molecular sieve structure), it further removes residual oils, suspended solids, and micro-particles. The graded particle size design of the filter media enables coarse filtration (first stage) and the filtration (second stage), producing effluent with oil content ≤6 ppm, SS ≤2 mg/L, and a median particle size < 1.5 µm. The backwash cycle is 8-12hours.

Treatment Process of Oilfield Produced Water

3. Integrated System

Featuring a skid-mounted design and fully automated control (with IoT and AI real-time monitoring), a single unit can achieve a treatment capacity exceeding 500m³/h. The produced water, after pre-treatment by the CDFU for oil removal, flows directly into the KFM, preventing filter media clogging and enhancing overall system stability.

This process draws on the operational experience of combining CDFU with walnut shell filters. However, as an upgraded activated filter media. KFM offers higher filtration precision and durability, making it suitable for both offshore platforms and onshore oilfields.

Technological Advantages

High Efficiency: The combination of the CDFU’s short retention time and the KFM’s high-precision filtration achieves an overall COD removal rate of ˃ 85%, significantly higher than the 70-85% removal rate of traditional CFU or IGF (Induced Gas Flotation) systems. It is well-suited for handling water with high emulsified oil and high salinity content, and operates at a treatment speed 3-8 times faster than conventional processes.

Economical: Purely physical, zero-chemical-addition process reduces operating costs to as low as RMB 0.375 per ton, representing a 35% reduction compared to conventional methods. The KFM filter media offers an extended lifespan (resistant to fouling and wear), resulting in low maintenance costs.

Environmental Sustainability: The process produces no secondary pollution and generates no sludge, complying with the GB 8978-1996 standard. It supports water re-injection, reduces freshwater consumption, and promotes sustainable development.

Compact Design & High Stability:The system occupies one-third the footprint of traditional setups. Its fully enclosed operation offers strong impact resistance (adaptable to pH 3-10), making it ideal for space-constrained oilfield environments.

Practical Application: For instance, in a project at the Changqing Oilfield, a similar CDFU+KFM combination system treated produced water at 20m³/h. The effluent met re-injection standards (oil content ≤10 ppm) while reducing costs by 20-30%.

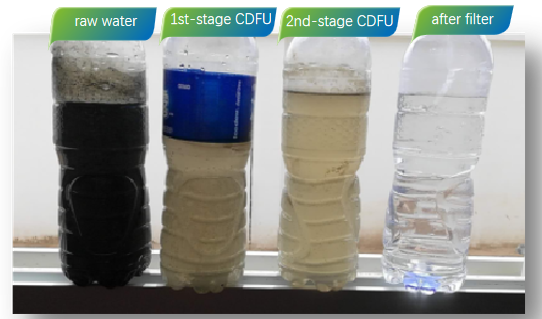

Sample of Influent, Effluent, and Equipment

This new process increases the efficiency of oilfield produced water treatment, promotes environmentally-friendly oil and gas development, and is applicable to oilfields worldwide, such as those in the Middle East or onshore projects in China.