Cyclonic Dissolved Gas Flotation Unit (CDFU): Technical Innovation and Performance Breakthrough

In the field of oily wastewater treatment, the Traditional Compact Flotation Unit (CFU) technology has long been hampered by bottlenecks such as low efficiency and poor stability. SINOKLE has independently developed the CDFU, which integrates core technologies including centrifugal separation and ultra-fine bubble generation, achieving a revolutionary upgrade in flotation technology. The following analysis will analyze from three aspects: technical principles, performance comparison, and practical application.

1. Innovation of Technical Principles

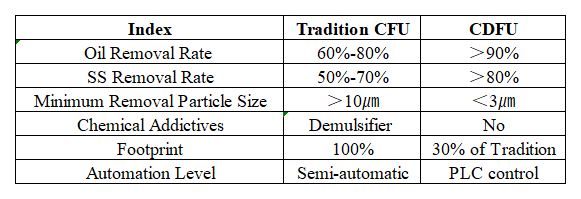

The traditional CFU relies on mechanical cutting or a jet device to generate bubbles (ranging from 300㎛ to 100㎛). The retention time is around 3 min with only 60% to 80% oil removal rate. What's worse, the treatment effect for emulsified oil and small suspended solids (<10㎛) is poor.

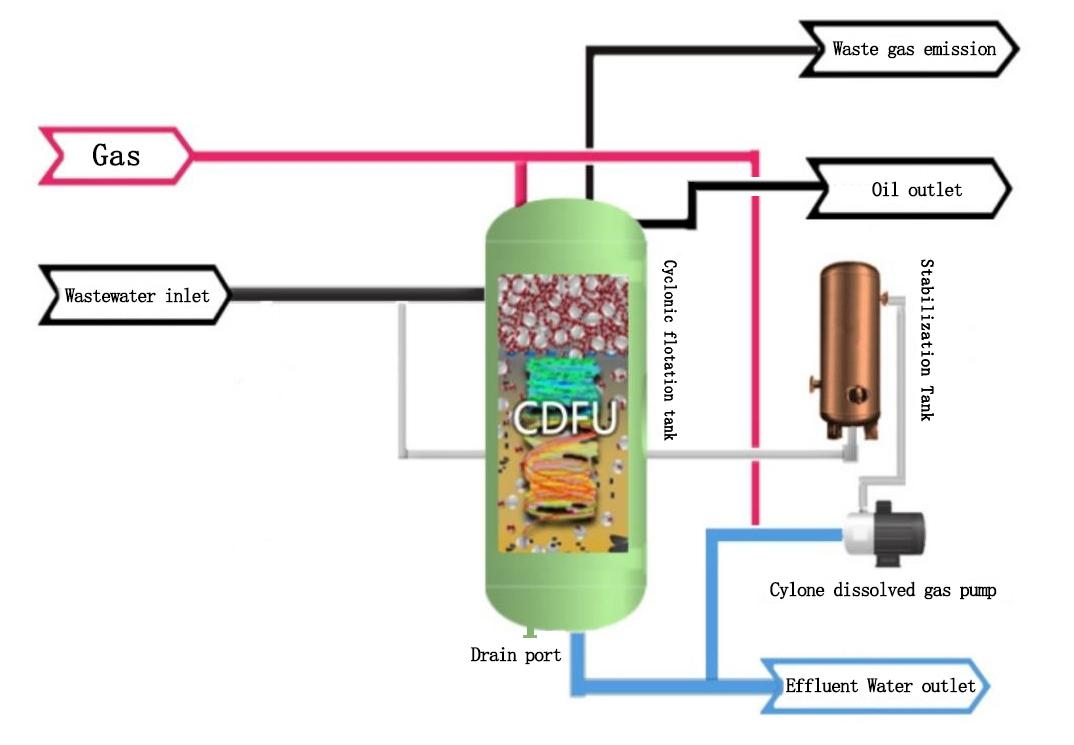

CDFU realizes a technical breakthrough through the following three aspects:

A. Tangential Inlet Design: The specialized inlet design forms a high-speed cyclonic field (3 times of centrifugal acceleration), increasing the collision and coalescence efficiency between oil droplets and micro-bubbles.

B. Micro-bubbles Technology: The Dissolved gas pump can generate uniform bubbles with 5㎛ to 30㎛. The specific surface area of micro-bubbles is 10 times larger than that of traditional bubbles, allowing them to have stronger adherence ability.

C. Dual Flotation Zones: A central cylinder divides the flotation tank into two zones: the inner flotation zone and the outer flotation zone. The space utilization rate has increased by 50, while the retention time has been shortened to 1 to 5 minutes.

2. Performance Comparison

Especially for challenging wastewater streams such as refinery acid water (with 16% oil content) and fracturing flowback fluid, the CDFU can consistently maintain effluent oil content at <100mg/L while reducing sludge generation by 90%.

3. Applications and Advantages

Refinery Industry: After adopting the CDFU system in a blackwater treatment project at a petrochemical enterprise in Xinjiang, the system demonstrated 110% impact load resistance while achieving a 40% reduction in operational energy consumption.

Oilfield Sector: For the treatment of fracturing flowback fluid, the integration of CDFU with Cyclonic Dissolved Ozone Flotation Unit (CDOF) technology enables rapid gel-breaking and viscosity reduction at low temperatures (20°C), while reducing chemical dosage by 70%.

Offshore Platforms: The skid-mounted design accommodates spatial constraints. Application data from an offshore oilfield demonstrates that CDFU equipment lifespan exceeds five years, with maintenance costs only one-third that of conventional CFU systems.

CDFU applied to the petrochemical blackwater treatment

4. Future Expectations

CDFU technology has been validated through numerous oily wastewater treatment projects globally. Its high-efficiency, low-carbon, and modular characteristics are driving the industry's transition from chemical treatment to physical purification. With ongoing intelligent upgrades (e.g., IoT-based remote monitoring), CDFU is poised to become a benchmark technology for industrial wastewater treatment worldwide.