Application of ozone catalytic oxidation process in wastewater treatment

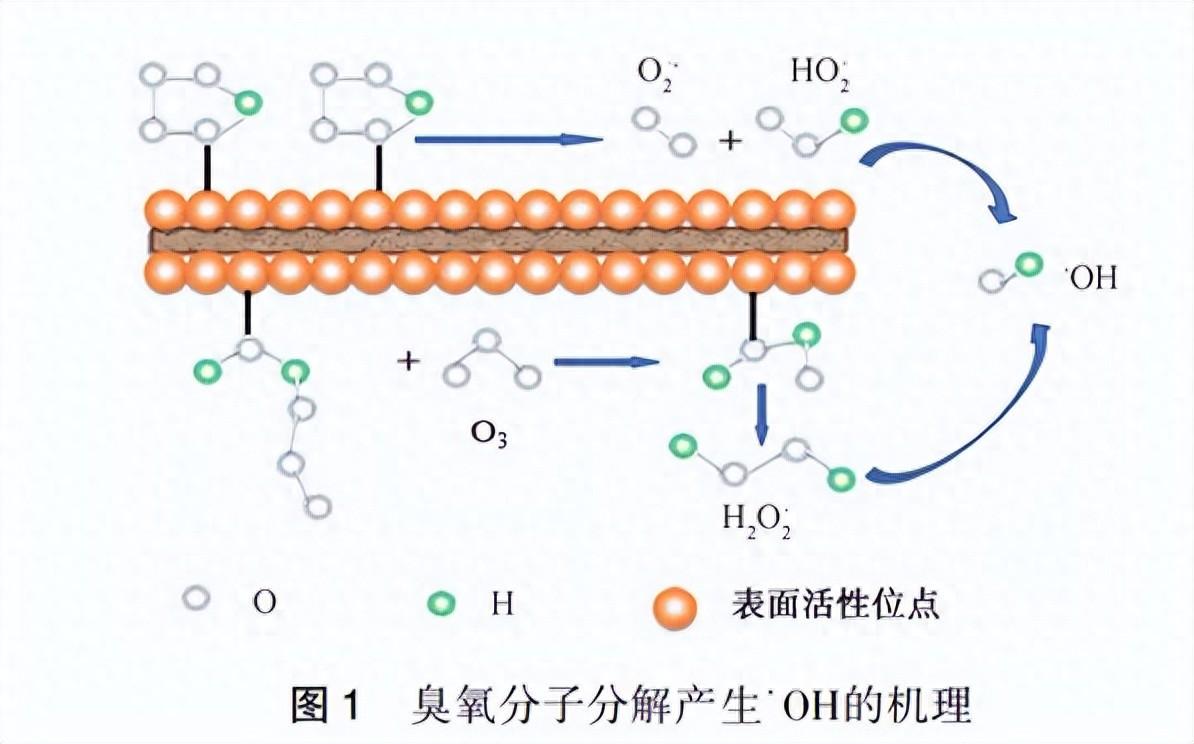

Ozone oxidation technology is a process of oxidative degradation of organic matter by using ozone and free radicals generated by its decomposition. By being produced in water. OH has a REDOX potential of up to 2.8V (2.07V for ozone molecules), and its oxidation capacity is second only to fluorine. It can react with various forms of pollutants in water (dissolved, emulsified, suspended, colloids and microorganisms, etc.) and convert complex organic matter into simple organic matter, acid and aldehyde, etc. At the same time, it can effectively remove turbidity, color, odor and sterilization.

The traditional direct ozone oxidation technology has the problems of slow reaction rate, strong selectivity of pollutants, low ozone utilization rate and high treatment cost, while the advanced ozone oxidation technology can effectively improve the ozone utilization rate and oxidation capacity, almost no selectivity of pollutants, strong comprehensive removal ability of various pollutants, and no secondary pollution. Advanced ozone oxidation process in sewage treatment has great application prospects, has been widely used in all kinds of sewage treatment fields, especially landfill leachate, petrochemical wastewater, pharmaceutical wastewater and other difficult sewage treatment.

Advanced ozone oxidation technology development:

Advanced catalytic oxidation such as O3/H2O2

O3/UV advanced oxidation

O3/ Ultrasonic advanced oxidation

O3/ Advanced oxidation of activated carbon

O3/ metal catalyst advanced oxidation, etc

On the basis of the existing advanced Ozone oxidation technology, SINOKLE has developed a new CDOF(Cyclonic Dissolved Ozone Flotation unit) process, creatively combining advanced ozone oxidation technology, swirl technology and dissolved gas flotation technology. Through the use of self-developed supercritical catalytic oxidation and highly efficient heterogeneous catalysts, cavitation supercritical catalysis can be achieved, and efficient ozone catalytic oxidation can be achieved in a fully closed automatic pressure vessel, which can efficiently and comprehensively remove pollutants from various difficult wastewater.

SINOKLE advanced ozone oxidation technology features are as follows:

(1) The first set of ozone multiple catalytic oxidation, swirl dissolved gas floating, coagulation and other technologies as one technology, efficient removal of COD, suspended matter, colloids, bacteria, viruses and so on.

(2) Multi-stage, multi-dimensional, multi-ozone catalytic oxidation reaction: pressure catalytic reaction, homogeneous and heterogeneous catalytic oxidation, hydraulic cavitation catalysis, micro-pressure catalytic oxidation, swirl fluidization reaction and other processes, the effect is stable and reliable.

(3) Special patent structure reactor, very fast reaction, residence time is less than 15min (traditional 90min), closed pressure operation, no ozone leakage, safe and environmental protection.

(4) The ozone utilization rate is above 99.98%, the ozone speculation ratio is 0.5~1.2 (traditional 2~4), which is only 1/5~1/2 of the traditional, and the operating cost is 1/3~1/2 of the traditional.

(5) DCS/PLC automatic control technology is used to accurately control the amount of ozone dosing, reaction level, pressure, tail gas concentration, etc., which can be automatically optimized according to water quality and reduce operating costs.

(6) The use of special catalysts, strong activity, high strength, large specific surface area, strong pollution resistance, PH value to adapt to a large range (acid, alkali), long-term effective.

(7) Unique catalyst backwashing, activation, regeneration process, catalyst performance long-term stability.

Application Case:

CDOF ozone advanced catalytic oxidation dissolved gas air flotation integrated device is applied to the landfill leachate treatment of a garbage incineration power plant in Shiyan, Hubei Province, with a daily processing capacity of 300 cubic meters. The COD of MBR effluent at the upstream of the inlet of the device is about 1300mg/L. After the treatment of CDOF ozone air flotation integrated device, the COD of CDOF effluent is less than 400mg/L. Water color ≤30, no odor. After the subsequent biochemical process treatment, the effluent COD is less than 20mg/L, ammonia nitrogen is less than 1mg/L, and total phosphorus is less than 0.2mg/L, reaching the surface Class III water standard to achieve stable and standard discharge.