Light Oil vs. Heavy Oil: The Water Divide You Never Knew

As the "lifeblood" of modern industry, petroleum extraction and processing generate substantial volumes of wastewater. However, not all crude oils share the same physical and chemical properties. Based on density and viscosity, crude oil is broadly classified into light crude oil and heavy (or viscous) oil. These two types differ significantly in their production processes—and consequently, in the characteristics, treatment complexity, and environmental impacts of the wastewater they generate. This article provides a comprehensive overview of the differences between wastewater produced during light and heavy oil operations.

1. Fundamental Differences Between Light and Heavy Oil

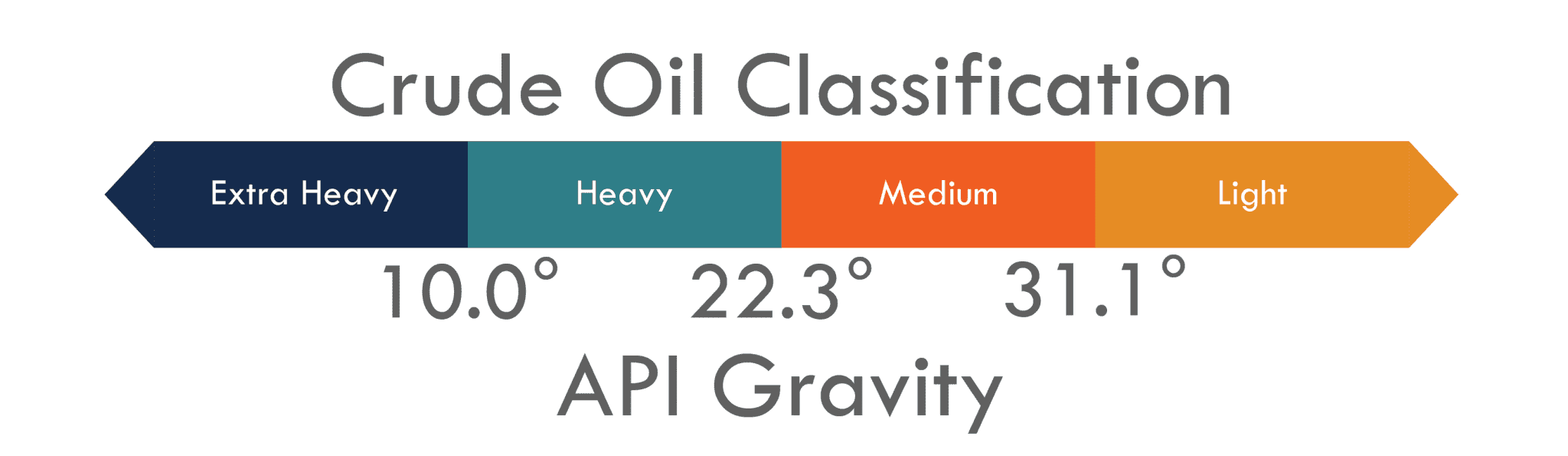

Light crude oil typically refers to oil with an API gravity greater than 31.1° (density less than 870 kg/m³). It flows easily, has low sulfur content, and is relatively straightforward to extract and refine.

In contrast, heavy (or viscous) oil has an API gravity below 22.3° (density above 920 kg/m³), exhibits high viscosity, and poor flowability. Extracting heavy oil often requires enhanced oil recovery (EOR) techniques—particularly thermal methods such as steam flooding or Steam-Assisted Gravity Drainage (SAGD).

These fundamental physical differences directly influence the nature of wastewater generated during production, transportation, and initial processing.

2. Wastewater from Light Crude Oil Production

2.1 Primary Sources

✔ Produced water: The largest wastewater stream, consisting of formation water brought to the surface along with oil.

✔ Drilling and completion fluids: Contain drilling muds, lubricants, corrosion inhibitors, and other chemicals.

✔ Equipment wash water: Used for cleaning storage tanks, pipelines, and processing facilities.

2.2 Typical Composition

✔ High salinity: Total dissolved solids (TDS) can reach tens of thousands of mg/L, dominated by Na⁺, Cl⁻, Ca²⁺, and Mg²⁺.

✔ Low oil content: Generally ranges from tens to hundreds of mg/L, as light oil separates readily from water.

✔ Trace organic compounds: Including BTEX (benzene, toluene, ethylbenzene, xylene) and polycyclic aromatic hydrocarbons (PAHs).

✔ Low levels of heavy metals: Such as nickel, vanadium, and lead, leached from subsurface minerals.

2.3 Treatment and Disposal

Due to efficient oil-water separation, light oil wastewater is relatively easier to treat. Common methods include:

✔ Dissolved air flotation (DAF)

✔ Filtration

✔ Biological treatment

✔ Reverse osmosis (for desalination and reuse)

✔ In many fields, treated produced water is reinjected into reservoirs for pressure maintenance—a form of resource recovery.

3. Wastewater from Heavy Oil Production

3.1 Primary Sources

✔ Thermal condensate: Formed when injected steam condenses underground; this constitutes the bulk of heavy oil wastewater.

✔ Produced water: Often contains high concentrations of emulsified oil due to the viscous nature of the crude.

✔ Boiler blowdown and softening waste: Generated from water pretreatment systems used to produce high-quality steam.

3.2 Typical Composition

✔ Extremely high salinity and hardness: TDS frequently exceeds 100,000 mg/L, with elevated calcium and magnesium levels that promote scaling.

✔ High oil content and stable emulsions: Oil droplets are fine and tightly bound in water, forming persistent emulsions resistant to separation.

✔ High silica content: Leached from reservoir rocks, leading to silicate scaling in equipment.

✔ Elevated temperature: Freshly produced wastewater can reach 80–100°C, increasing energy demands for treatment.

✔ Residual chemical additives: Including demulsifiers, scale inhibitors, and corrosion inhibitors.

3.3 Treatment Challenges

Heavy oil wastewater poses three major treatment hurdles:

✔ Difficult emulsion breaking: Requires strong chemical demulsifiers or advanced techniques like electrocoagulation or ultrasonic treatment.

✔ Severe scaling potential: Necessitates pretreatment such as lime softening or ion exchange.

✔ Low reusability: Due to complex chemistry, most heavy oil wastewater cannot be recycled as boiler feedwater, often requiring energy-intensive end-of-pipe solutions like evaporation and crystallization.

In regions such as China's Liaohe Oilfield and Canada's oil sands, wastewater treatment can account for over 15% of total heavy oil production costs.

4. Environmental Impacts and Management Trends

Improper discharge of either type of wastewater can contaminate soil, groundwater, and surface water, posing risks to ecosystems and human health. However, heavy oil wastewater generally presents greater environmental hazards due to its high salinity, oil content, and emulsion stability.

Global best practices now emphasize:

✔ Source reduction: Optimizing production methods to minimize wastewater generation.

✔ Tiered treatment and resource recovery: Reclaiming water, salts, and even thermal energy.

✔ Smart monitoring: Using sensors and AI for real-time process control.

✔ Green chemistry: Developing low-toxicity, biodegradable oilfield chemicals.

Conclusion

Although both light and heavy crude oils originate from the same geological sources, the wastewater they generate during production differs markedly in composition, treatment requirements, and environmental risk. Understanding these distinctions is essential for designing effective, cost-efficient, and environmentally sound wastewater management strategies. As the energy sector transitions toward sustainability, the efficient and low-carbon treatment of petroleum-related wastewater remains a critical challenge for the industry's future.