Is Your "Clean" Electricity Hiding a Dirty Secret? The Truth About Power Plant Wastewater.

"Clean Electricity, Dirty Water?" — Unveiling the "Past and Present" of Power Plant Wastewater

The electricity indispensable to our daily lives is not always produced in a "clean" manner. Especially for traditional coal-fired power plants, the process of converting chemical energy into electrical energy generates substantial industrial wastewater. If improperly treated, this wastewater can pose a severe threat to the environment. This article delves into the "past" (origins and composition) and "present" (treatment and discharge) of power plant wastewater.

I. "Past": Origins and Complex Composition of Power Plant Wastewater

Wastewater generation in power plants is an integral part of the entire electricity production process, primarily stemming from the following sources:

1. FGD Wastewater (Flue Gas Desulfurization Wastewater)

Source: This is the most representative and challenging wastewater to treat in coal-fired power plants. To control sulfur dioxide (SO2) emissions, power plants widely adopt the limestone-gypsum wet flue gas desulfurization (FGD) process. During this process, the slurry within the absorption tower circulates continuously, leading to the gradual accumulation of impurities and heavy metal ions. A portion of this slurry must be periodically discharged for treatment, which constitutes FGD wastewater.

Composition Characteristics: High salinity, high hardness, high corrosivity, and high toxicity. It contains significant amounts of suspended solids (e.g., gypsum, fly ash), high concentrations of chlorides and sulfates, as well as various heavy metal ions such as mercury, cadmium, and lead.

2. Cooling Tower Blowdown

Source: The steam turbines in power plants generate enormous amounts of heat during operation, which must be cooled by a circulating cooling water system. As cooling water evaporates and dissipates heat in the cooling tower, the salts and minerals in the water become increasingly concentrated. To prevent scaling and corrosion in pipes and equipment, a portion of the highly concentrated circulating water must be periodically discharged, known as cooling tower blowdown.

Composition Characteristics: High salinity and high hardness. It primarily contains calcium, magnesium ions, and other total dissolved solids (TDS).

3. Chemical Water Treatment Wastewater

Source: Power plant boilers have extremely high water quality requirements for makeup water, necessitating a series of complex chemical treatments such as coagulation, clarification, filtration, ion exchange, and reverse osmosis (RO). These processes generate backwash water, regeneration wastewater, and concentrated brine.

Composition Characteristics: Complex composition, potentially including acid-alkaline wastewater, high-concentration salts (from RO concentrate), and trace organic compounds.

4. Domestic Sewage and Other Miscellaneous Drainage

Source: Includes domestic sewage from plant employees, floor washing water within the plant area, and rainwater runoff.

Composition Characteristics: Compared to the aforementioned types, this wastewater has a relatively lower pollution level, and treatment processes are relatively mature.

II. "Present": Power Plant Wastewater Treatment Processes and Discharge Standards

Faced with wastewater of complex composition, power plants must employ a complete and efficient wastewater treatment system to ensure it meets national or local discharge standards before release or reuse.

1. Conventional Treatment Processes

Pretreatment: Primarily includes units such as screening, equalization basins, coagulation, sedimentation, clarification, and filtration. Its purpose is to remove most suspended solids, colloids, and some organic matter from the wastewater, creating favorable conditions for subsequent advanced treatment.

Advanced Treatment: For wastewater that still contains high concentrations of dissolved salts and refractory organic compounds after pretreatment, advanced treatment is required.

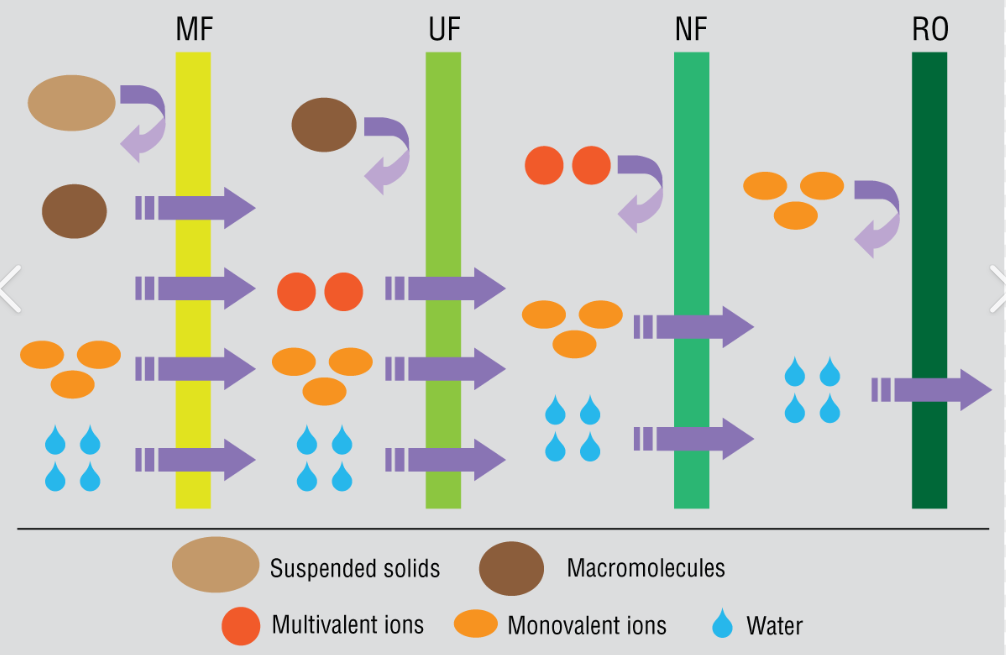

Membrane Separation Technology: Such as ultrafiltration (UF) and reverse osmosis (RO), which can effectively remove salts, heavy metals, and most organic matter from water. They are core technologies for achieving wastewater reuse and "zero liquid discharge."

Advanced Oxidation Processes (AOPs): Such as ozonation and Fenton oxidation, used to decompose refractory organic pollutants in water.

2. Specialized Treatment for High-Difficulty Wastewater

FGD Wastewater Treatment: Due to its high salinity and toxicity, the treatment process is more complex. A separate treatment system is typically required, including pretreatment steps such as neutralization, coagulation, sedimentation, and clarification, before it enters the plant's comprehensive wastewater treatment system for advanced processing. For power plants pursuing "zero liquid discharge," pretreated FGD wastewater may also enter an evaporation and crystallization system, where water is completely evaporated and salts are discharged as solids, achieving true liquid-free discharge.

3. Reuse and "Zero Liquid Discharge" (ZLD)

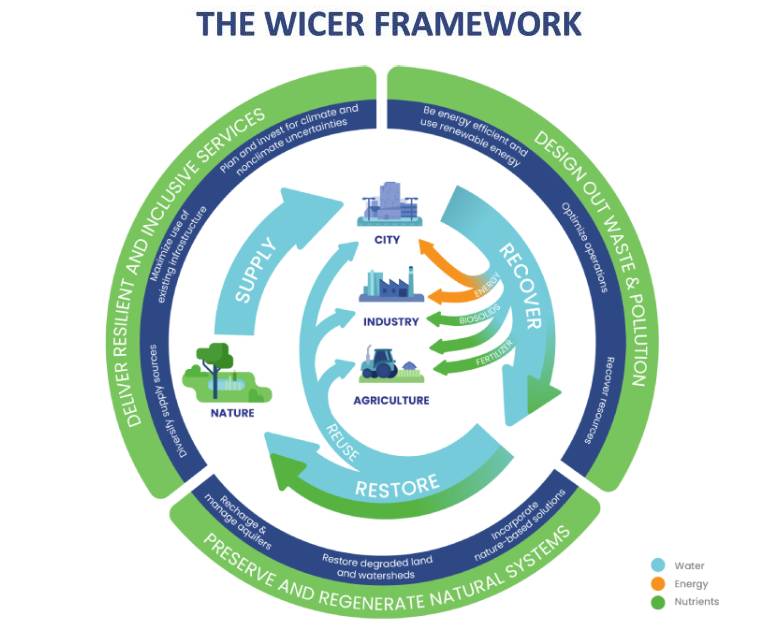

With the growing scarcity of water resources, recycling treated wastewater for use in the plant's circulating cooling water system, boiler makeup water pretreatment, and other processes has become an industry trend.

Zero Liquid Discharge (ZLD) is currently the highest goal in power plant wastewater treatment. It involves treating and reusing all wastewater, ultimately discharging only solid waste (e.g., salt slag) and no liquid wastewater into the environment. This not only solves water pollution problems but also maximizes water resource utilization, albeit at a higher capital and operational cost.

III. Conclusion

Power plants, particularly coal-fired ones, do generate "dirty" wastewater in the process of producing "clean" electricity. However, through the continuous development and application of advanced water treatment technologies, this wastewater can be effectively managed and utilized.

The progress in water treatment within the power sector, from "meeting discharge standards" to "wastewater reuse" and the pursuit of "zero liquid discharge," reflects the trend of harmonizing industrial development with environmental protection. Looking ahead, with further technological innovation and increasingly stringent environmental requirements, we can be confident that electricity production will become even greener and more sustainable.