Wastewater as a Resource: Unveiling the Hidden Value in Oilfields

When it comes to oilfield wastewater, most people associate it with turbid liquid, peculiar odors, and environmental pollution risks. In fact, after treatment, oilfield wastewater can not only produce reusable water but also recover various useful components such as oil-based substances, mineral salts, and chemical agents. With the upgrading of resource utilization technologies, oilfield wastewater has gained significant resource value. This article will sort out the extraction methods and application approaches of these useful substances.

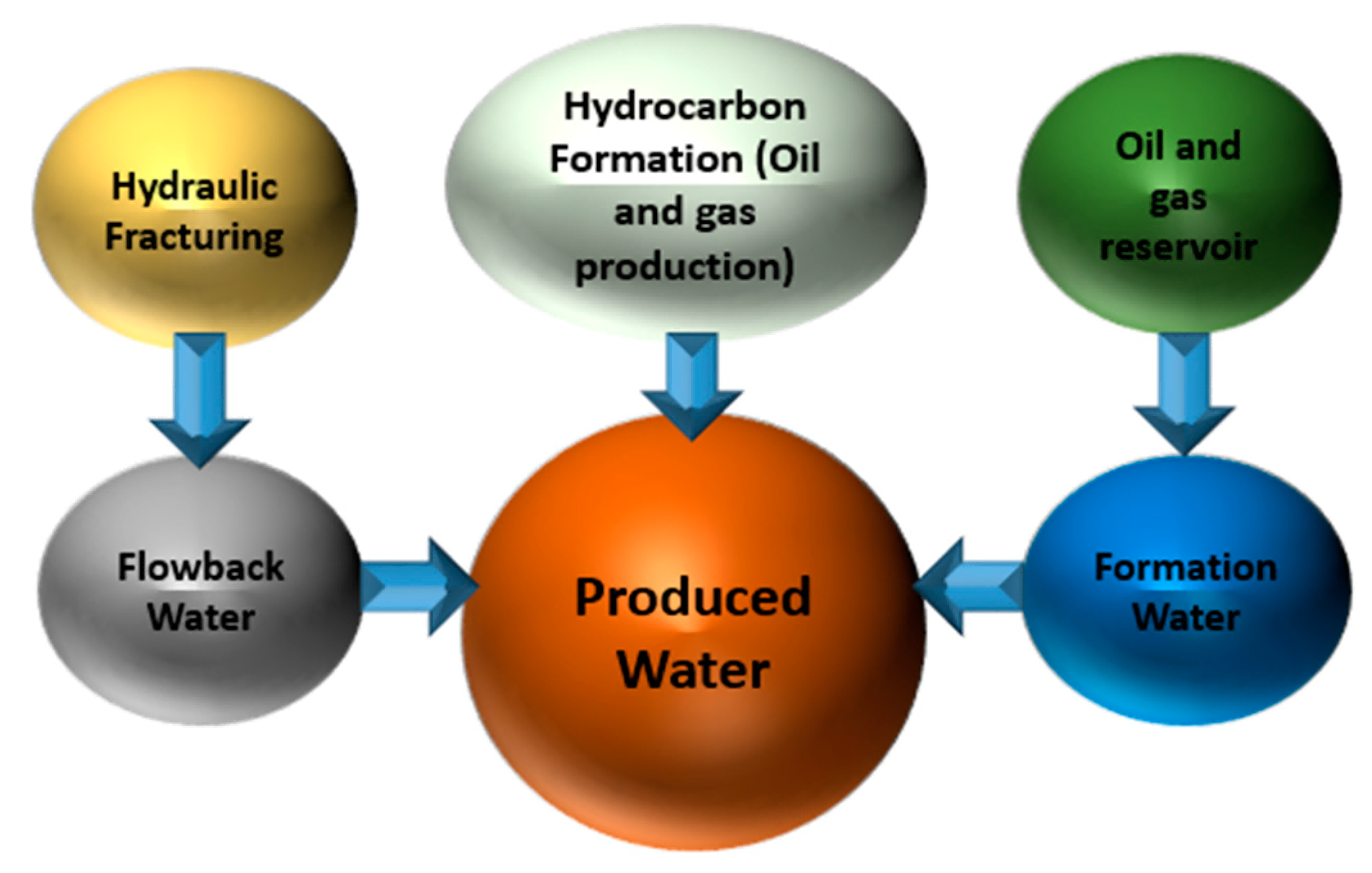

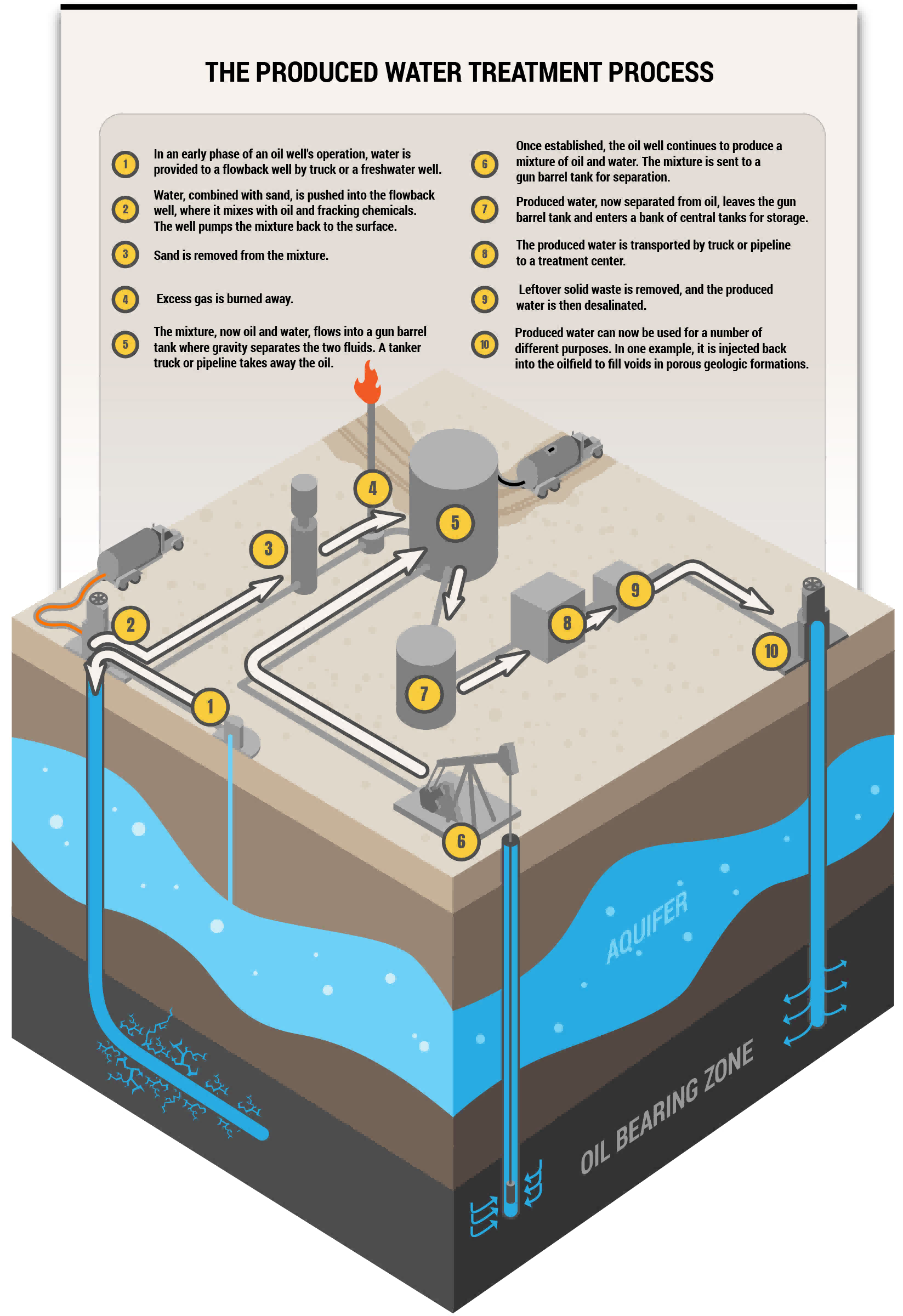

The complex composition of oilfield wastewater endows it with resource properties. Such wastewater includes formation water (rich in salts and minerals) produced along with crude oil, unreacted chemical agents during extraction (e.g., fracturing fluid, demulsifier), and incompletely separated crude oil components. Through scientific separation and purification processes, these components can be converted into economically valuable resources, realizing the resource utilization of wastewater.

I. Core Recyclable Substance: Oil-Based Substances

Oil-based substances are the most economically valuable recyclable objects in oilfield wastewater and also the earliest components to realize industrial recycling. Oil in oilfield wastewater exists in forms such as floating oil, dispersed oil, and emulsified oil, among which floating oil accounts for the highest proportion and has the lowest recovery difficulty.

The recovery of oil-based substances is centered on physical separation technologies, adapting to different forms of oil: floating oil utilizes the density difference between oil and water, naturally floats up in an oil separator, and is then collected by an oil skimmer with a recovery rate of over 80%; dispersed oil adopts air flotation technology, where microbubbles are introduced into water to adsorb oil droplets and float up for separation, and the recovery efficiency can be increased to over 95% when used with flocculants; emulsified oil needs to first undergo chemical demulsification (adding demulsifiers) to destroy the stable structure, allowing small oil droplets to aggregate before separation and recovery.

The recovered oil-based substances can re-enter the refining process to produce gasoline, diesel, and other products after purification; the recovered oil with lower purity can be used as fuel for industrial boilers. Data from an oilfield shows that by optimizing the oil removal process, over 5,000 tons of crude oil can be recovered from wastewater annually, creating economic value of tens of millions of yuan and reducing the risk of oil pollution.

II. Resource Utilization of High-Salinity Wastewater: Recovery of Mineral Salts and Water Resources

Most oilfield wastewater is high-salinity water, and the salinity of some wastewater exceeds 200,000 mg/L, far higher than that of seawater. The mineral salts such as sodium chloride, sodium sulfate, potassium chloride, and magnesium sulfate dissolved in this high-salinity wastewater are all important industrial raw materials, and the water after desalination can also realize resource utilization.

The core of mineral salt and water resource recovery is the "desalination-crystallization" process: first, membrane separation technologies such as reverse osmosis and electrodialysis are used to separate high-salinity wastewater into fresh water and concentrated brine—fresh water can be directly used for oilfield reinjection, equipment cleaning, or greening; concentrated brine enters an evaporation crystallization system (e.g., MVR evaporation crystallization), and salts are precipitated in crystalline form through low-temperature evaporation and cooling crystallization. Utilizing the differences in crystallization temperature and solubility of different salts, precise separation can be achieved through fractional crystallization to obtain high-purity industrial salt products.

The recovered mineral salts have a wide range of uses: sodium chloride can be used for chemical production and road deicing; sodium sulfate is a raw material for glass manufacturing and detergent production; potassium chloride can be used as fertilizer or chemical intermediate. A treatment station in an oilfield in Northwest China adopts the "membrane separation + evaporation crystallization" process, recovering 1.2 million cubic meters of fresh water and 30,000 tons of industrial salt annually, which not only solves the problem of wastewater discharge but also alleviates the local shortage of water resources and industrial raw materials.

III. Recycling of Chemical Agents and Polymers

A large number of chemical agents need to be injected into the formation during oilfield extraction, including fracturing fluid (containing polymers such as polyacrylamide and guar gum), demulsifiers, and scale inhibitors. Some agents will flow back with wastewater; their recovery and reuse can reduce extraction costs and environmental impact.

Polymers in fracturing fluid (e.g., polyacrylamide) are the most valuable agent components for recovery, with high prices and excellent thickening and sand-carrying properties. During recovery, coagulation sedimentation and filtration are first used to remove suspended solids and oil stains from wastewater, then ultrafiltration membrane separation or chemical precipitation regeneration technology is adopted to separate and purify polymers, and the fracturing fluid can be reconfigured after adjusting the concentration. After an oil shale field adopted this technology, the reuse rate of fracturing fluid reached over 90%, and the fracturing cost per well was reduced by 15%-20%.

In addition, the effective components of demulsifiers and scale inhibitors in wastewater can be recovered through adsorption and extraction technologies and reused after modification. This agent recycling mode has realized the transformation of oilfield extraction from one-way consumption to circular utilization, greatly improving resource utilization efficiency.

IV. Oilfield Wastewater Resource Utilization: A Core Direction for Green Development

Oilfield wastewater resource utilization has both economic and environmental value: recovering oil can reduce oil pollution, recovering water resources can alleviate the water shortage in production areas, and recovering chemical agents can reduce environmental pressure. This resource utilization mode is a core direction for the green transformation of the petroleum industry.

In the future, digital and intelligent technologies will promote the precise development of resource utilization, optimizing recovery processes through big data; cross-industry collaboration will be further deepened to form a closed-loop industrial chain of "oilfield wastewater - resources - industrial products", maximizing the resource value of wastewater.

The resource value of oilfield wastewater is reflected not only in specific material wealth but also in the wisdom of sustainable development of the industry. The transformation from passive pollution control to active resource utilization redefines the value of wastewater and achieves a win-win situation between energy development and ecological protection.