Enhanced Oil Recovery (EOR): Unlocking Trapped Reservoir Potential

Oil recovery from reservoirs is a complex process influenced by various factors. Generally, only a portion of the total oil present in a reservoir can be extracted using primary recovery methods, typically ranging from 5% to 30%. This leaves a significant amount of oil untapped. However, through the application of advanced techniques such as Enhanced Oil Recovery (EOR), it becomes possible to increase the amount of oil recovered from a reservoir beyond what is achievable with primary methods. Three major categories of EOR are commercially successful to varying degrees:

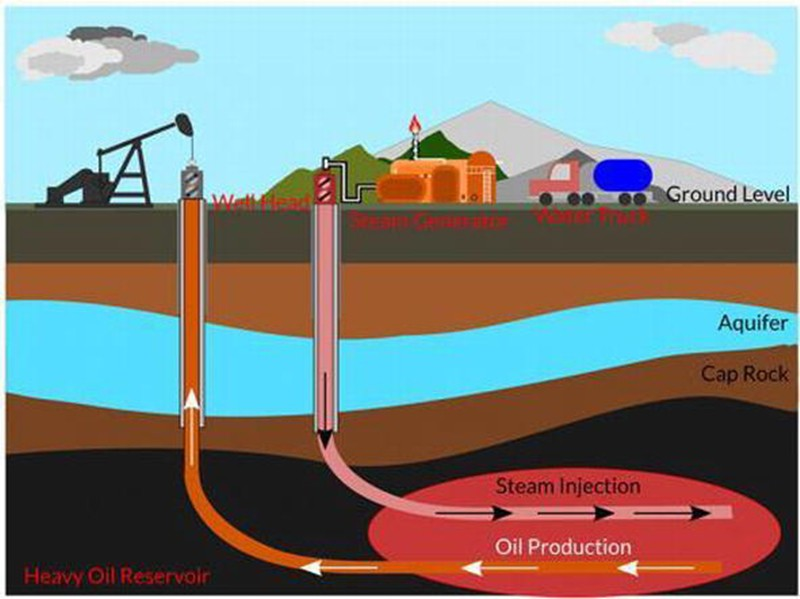

1. Thermal recovery, which involves the introduction of heat, such as the injection of steam, to lower the viscosity, or thin, the heavy viscous oil, and improve its ability to flow through the reservoir.

Steam Flooding: This is a well-established EOR technique highly effective for heavy oil reservoirs. Hot steam is injected into the reservoir through injection wells, heating the surrounding rock and oil. The increased temperature reduces oil viscosity, making it flow more freely towards production wells. Steam flooding requires a significant amount of energy and water to generate the steam, making it a relatively expensive technique.

In-Situ Combustion: This method involves a controlled underground fire within the reservoir. Air or oxygen is injected, and a small portion of the oil is ignited. The combustion process generates heat that mobilizes the surrounding oil, similar to steam flooding. However, in-situ combustion requires careful monitoring to avoid uncontrolled burning and potential environmental damage.

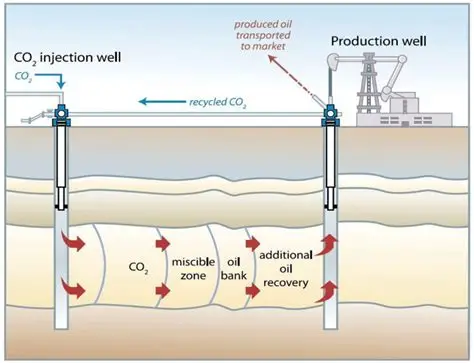

2. Gas injection, which uses gases such as natural gas, nitrogen, or carbon dioxide (CO2) that expand in a reservoir to push additional oil to a production wellbore, or other gases that dissolve in the oil to lower its viscosity and improves its flow rate.

Miscible Gas Flooding: This EOR technique utilizes miscible gases, typically carbon dioxide (CO2), which can mix with the oil at reservoir conditions. The injected gas reduces the oil’s viscosity and allows it to flow more easily. Additionally, CO2 flooding can have the added benefit of acting as a form of carbon capture and storage (CCS) as the injected CO2 remains trapped underground. However, miscible gas flooding is highly dependent on reservoir pressure and oil properties for successful mixing to occur.

Water-Alternating-Gas (WAG) Injection: This IOR method involves injecting water and gas alternately into the reservoir. The water helps to maintain reservoir pressure and displace oil, while the gas improves sweep efficiency by reducing the channeling of water through the reservoir. WAG injection offers a cost-effective approach compared to some other EOR techniques and can be applied to a wider range of reservoir conditions.

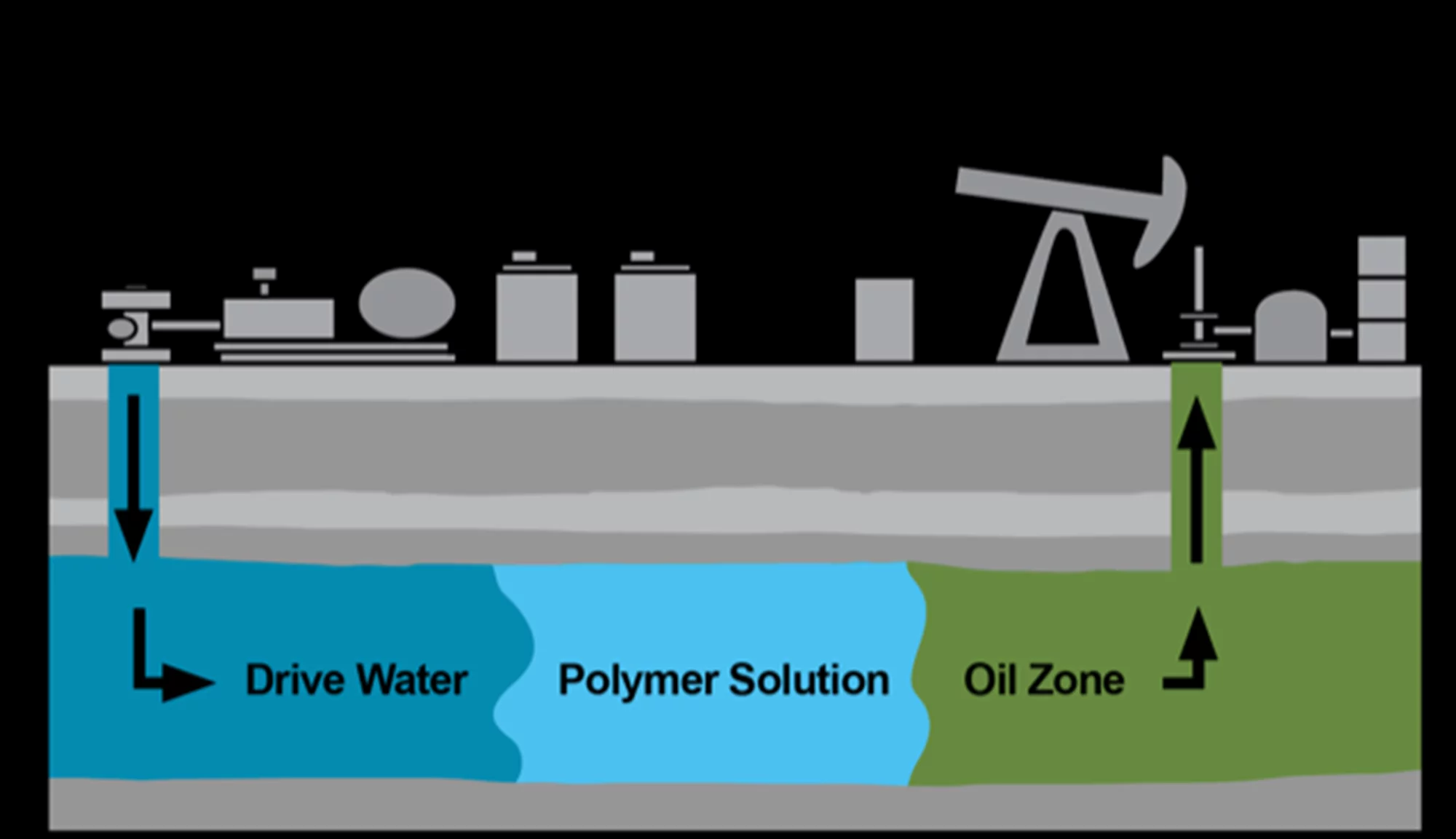

3. Chemical injection, which can involve the use of long-chained molecules called polymers to increase the effectiveness of waterfloods, or the use of detergent-like surfactants to help lower the surface tension that often prevents oil droplets from moving through a reservoir.

Each of these techniques has been hampered by its relatively high cost and, in some cases, by the unpredictability of its effectiveness.

Polymer Flooding: In this IOR technique, specially formulated polymers are added to the injected water. These polymers increase the viscosity of the water, improving its sweep efficiency. This translates to better contact between the injected water and the oil, displacing a greater volume of oil towards producing wells. Polymer flooding is a relatively cost-effective IOR method and can be applied to a wider range of reservoir conditions compared to some other EOR techniques.

Surfactant Flooding: Surfactants are chemicals that lower the interfacial tension between oil and water. Imagine oil and water as separate beads. Surfactants act like a soap, allowing these beads to merge and become more mobile. This allows previously trapped oil to flow more readily towards producing wells. Surfactant flooding can be particularly effective for lighter oils, but it can be more expensive than polymer flooding due to the specialized chemicals involved.

4. Enhanced Recovery Techniques

Waterflooding Optimization: This improved IOR strategy emphasizes refining the waterflooding process, which is the most prevalent secondary recovery method. By utilizing advanced monitoring and reservoir modeling tools, it aims to develop more effective water injection schemes that enhance contact with the residual oil. Moreover, wellbore stimulation methods such as hydraulic fracturing or acidizing can be applied to increase the flow capacity of both injected water and produced hydrocarbons, thereby further enhancing recovery efficiency.