SINOKLE’s Innovative Process Solves Industry Challenge: Electronic Desalination Wastewater Treatment Project Successfully Commissioned

Recently, the skid-mounted equipment for oil removal from electric desalting drainage in the atmospheric and vacuum unit of PetroChina Yunnan Petrochemical, constructed by Shenzhen Clear Science & Technology Co., Ltd., was officially delivered and put into operation. With a designed treatment capacity of 100 cubic meters per hour, this project marks another significant recognition of SINOKLE's technical expertise in the field of refinery wastewater treatment, providing a new benchmark for the industry's green transformation.

On-spot Electronic Desalination Wastewater Treatment Device

Treatment Challenges and Limitations of Conventional Processes

Electronic desalination drainage is a high-oil-content wastewater generated during the refining process, characterized by complex composition and a high degree of emulsification, making it difficult to treat and meet discharge standards through conventional methods. Traditional processes typically rely heavily on chemical agents for demulsification and flocculation, which not only incur high operating costs but also generate large amounts of oily sludge (classified as hazardous waste), posing risks of secondary pollution. Additionally, the treatment efficiency is highly susceptible to fluctuations in water quality.

Innovative Process: Purely Physical Method for Oil Removal

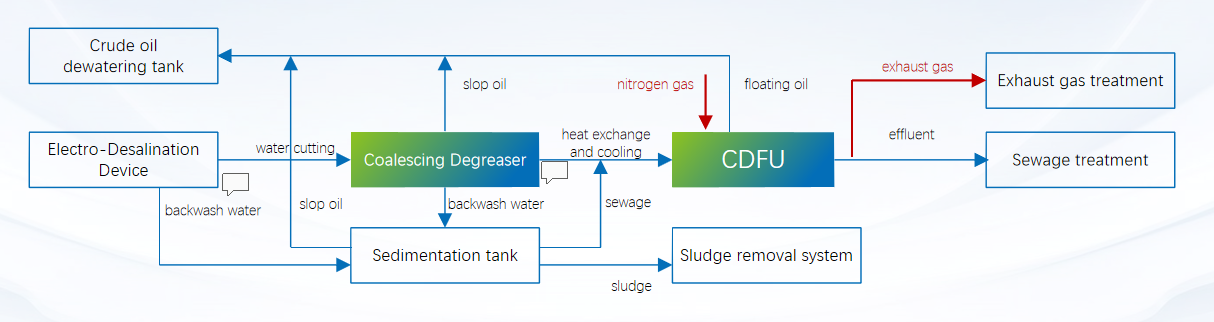

In this project, SINOKLE utilizes its patented technologies "Coalescing Pressure Degreaser + Cyclonic Dissolved Gas Flotation Unit (CDFU)" as integrated process.

Diagram of the Electric desalination wastewater treatment process

1. The Coalescing Pressure Degreaser utilizes specially designed coalescing filler, leveraging the coarse-graining principle (Stokes' Law) and a CFD-optimized flow field design to rapidly coalesce and enlarge fine oil droplets for effective separation, significantly enhancing oil removal efficiency.

2. The CDFU efficiently removes residual suspended oil particles and fine solids in the water by generating microfine bubbles.

3. The entire system operates without the addition of any chemicals, achieving true physical demulsification and oil removal.

New Process Highlights Multiple Advantages

1. Pure Physical Separation & Eco-Friendly: The entire process operates without chemical additives, preventing the generation of oily sludge at the source and completely resolving the challenge of hazardous waste disposal.

2. Resource Recovery & Cost-Effective: The recovered crude oil is of high quality and can be recycled back into the refining process, generating direct economic benefits.

3. Stable Compliance & High Efficiency: The system demonstrates strong resistance to shock loads and delivers consistent effluent quality. Performance tests confirm that the oil content is consistently reduced to below 30 mg/L, far exceeding the technical agreement requirements.

4. Skid-Mounted, Space-Saving & Short Installation Cycle: The highly integrated skid-mounted design allows for a short construction period and can be installed online without shutting down the unit, providing significant convenience to the client.

On-spot Electronic Desalination Wastewater Treatment Device

Consistently Meeting Standards Earns Industrial Praise

Since its commissioning, the high-efficiency flotation facility has consistently met all technical agreement requirements in both daily operation and performance tests. Its exceptional treatment performance has effectively ensured the safe operation of the downstream wastewater treatment plant, earning high praise and recognition from the owner, PetroChina Yunnan Petrochemical.

Performance of Electronic Desalination Wastewater of Sinopec (Yunnan)

Mature Process, Outstanding Performance

The electronic desalination wastewater treatment technology developed by Cleantech has become a stable and mature solution, with a wide range of successful applications across China. The company has previously provided similar systems for multiple large-scale refineries, including Sinopec Cangzhou Refining (1,200 m³/d), PetroChina Sichuan Petrochemical (1,700 m³/d), PetroChina Jinxi Petrochemical (1,200 m³/d), and Urumqi Petrochemical (3,600 m³/d). With treatment capacities ranging from tens to hundreds of cubic meters per hour, SINOKLE's projects are distributed nationwide, demonstrating the technology’s reliability and adaptability through extensive market validation.

The successful delivery of the Yunnan Petrochemical project once again highlights SINOKLE’s leading expertise in high-end environmental equipment manufacturing and industrial wastewater treatment. It further reinforces the company's role as a trusted partner for refining enterprises seeking to achieve environmental compliance, reduce costs, enhance efficiency, and transition toward green development.