New technology of fracturing flowback fluid treatment

Hydraulic fracturing technology is the main means to develop low permeability reservoir and unconventional oil and gas. Fracturing flowback fluid generated during fracturing contains many harmful substances such as oil, phenols, formaldehyde, guanidine gum, etc., which has complex components, high emulsification degree, strong stability, and difficult treatment. If discharged or reinjected into the formation without effective treatment, it will cause serious pollution and damage to the environment. Researchers mostly use the combination of physical, chemical and biological methods to deal with fracturing flowback fluid. The traditional treatment methods generally have problems such as long processing process and multiple equipment, and large dosage of chemicals leads to high operating costs.

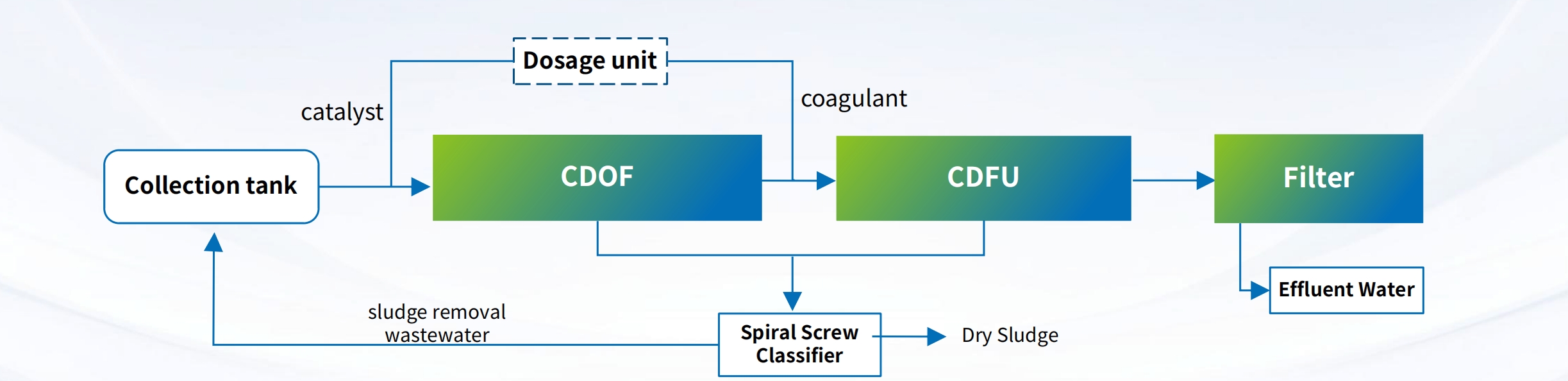

Compared with the traditional treatment methods, SINOKLE Technology has developed a new fracturing flowback fluid treatment process. The fracturing flowback fluid uses coagulation precipitation + CDOF (oCyclonic Dissolved Ozone Flotation unit) +CDFU (Cyclonic Dissolved gas Flotation Unit) +KFM (active filter material filter) treatment process to initially remove flocculent suspended matter and oil in the mixed fluid. CDOF (Cyclonic Dissolved Ozone Flotation unit) integrates multiple ozone oxidation, swirling dissolved air floatation, coagulation and other technologies to efficiently remove suspended matter and colloids in wastewater, and achieve the effect of rubber breaking and viscosity reduction; CDFU Cyclonic Dissolved gas Flotation Unit) can efficiently and quickly remove free oil, emulsified oil and suspended matter in wastewater by applying a large number of ultrafine bubbles. After the air flotation treatment, the effluent is deeply filtered through the fine filter to ensure that the effluent is stable and up to standard.

Figure 1. Flowback fluid treatment process flow chart

Technical features:

It has strong adaptability and can adapt to the processing requirements of flowback fluids with different properties generated by different fracturing fluid systems and different fracturing processes.

Good impact resistance, in the water quality, water quantity, temperature and other large changes, to ensure that the effluent water quality meets the needs of users;

CDOF, CDFU for the company's patented products, efficient removal of oil, removal of suspended matter, quickly achieve the effect of rubber breaking and viscosity reduction;

Short residence time (traditional 1/5), small footprint (traditional 1/3), skid compact equipment, mobile, can achieve fast and efficient processing on the spot;

Less chemical consumption, less sludge, less supporting equipment, low operating costs;

Fully automated, closed with pressure operation, safety and environmental protection.

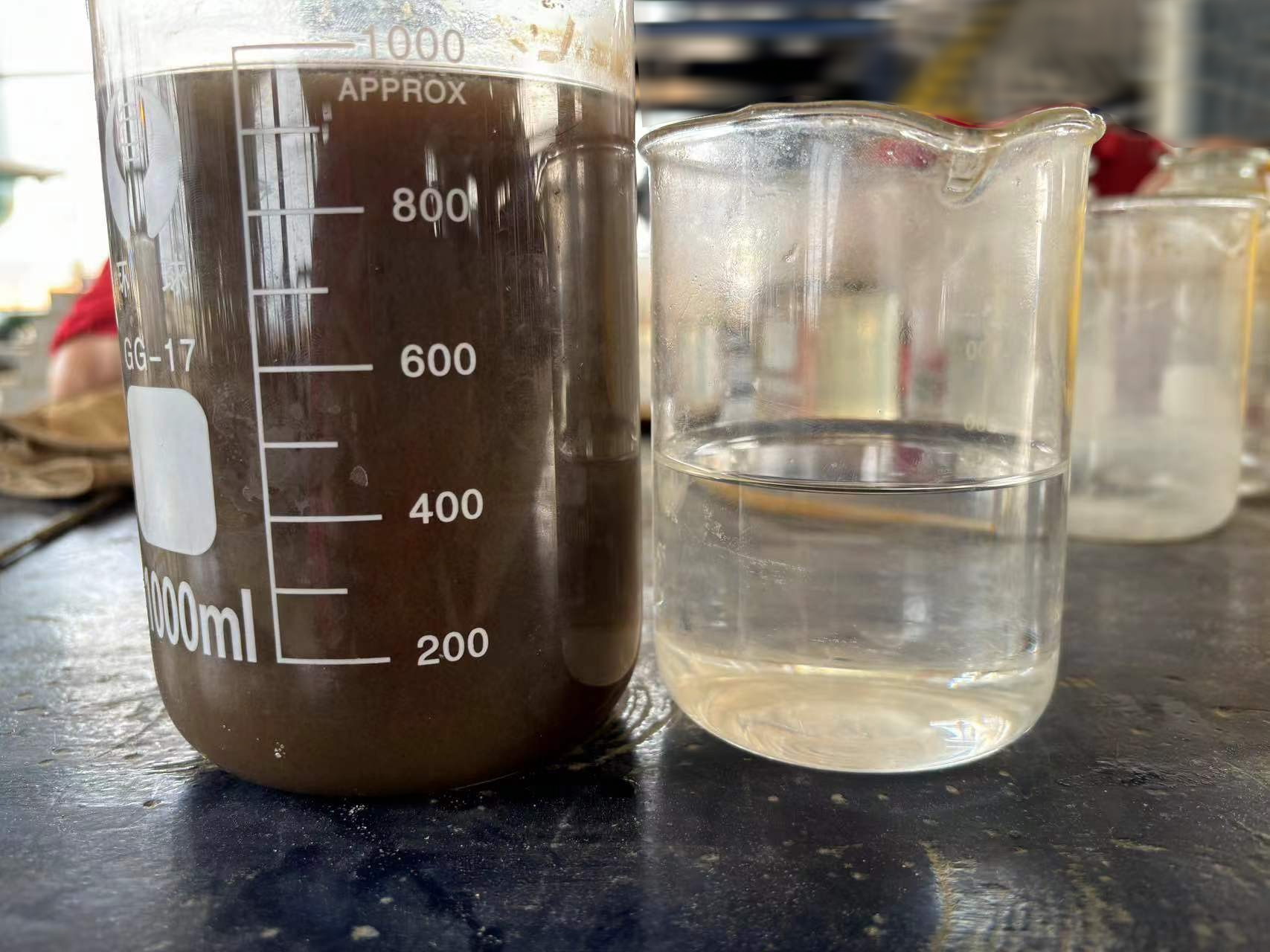

FIG. 2 On-site treatment effect of fracturing flowback fluid (comparison of inlet and outlet water)