Heterogeneous Catalytic Ozone Oxidation: A New Solution for Efficient Treatment of Refractory Wastewater

SINOKLE's heterogeneous ozone catalyst (such as the KHC series, typical model KHCPC1001) is an advanced catalyst specifically designed for Advanced Oxidation Processes (AOPs). This catalyst integrates ozone oxidation technology and is specialized for treating refractory organic wastewater.

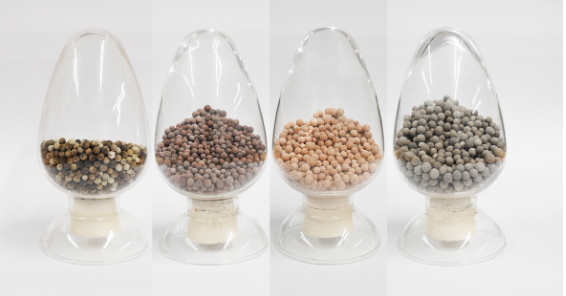

Heterogeneous Ozone Catalysts from SINOKLE Series

1. High Catalytic Activity

Through the adaptation of advanced preparation technology, the optimized composition, the catalyst possesses a huge specific surface area (achieved via a three-level pore system: macropores ˃ 50nm, mesopores 2-50nm, micropores < 2 nm), providing more active sites and significantly enhancing both ozone decomposition efficiency and pollutant degradation rate.

Under the action of catalysts, ozone efficiently generates hydroxyl radicals (OH, with an oxidation potential of 2.8V), achieving efficient mineralisation of refractory organic substances (such as phenols, cyanides, and antibiotics), with a COD removal rate of over 80%.

2. Wide pH Adaptability

It maintains stable catalytic activity with the pH range of 3-10, overcoming the reliance of traditional homogeneous catalysts (such as Fe²⁺/H₂O₂) on acidic conditions and adapting to complex water quality conditions (e.g., pH fluctuations in industrial wastewater).

3. No Secondary Pollution

The heterogeneous design prevents metal ion leaching, complies with stringent emission standards (e.g., GB8978-1996 heavy metal discharge standards), and eliminates the risk of secondary pollution.

4. High Stability and Long Service Life

The catalyst exhibits excellent thermal and chemical stability, with the lifespan typically exceeding 5 years. It is resistant to high temperatures and corrosion, making it suitable for long-term operation.

Surface modification technology enhances its anti-poisoning capacity, reducing the risk of catalyst deactivation.

5. Efficient Mass Transfer

Three-level pore system (macropores enhance mass transfer, mesopores increase active site exposure, and micropores augment specific surface area) optimizes the diffusion of reactants and products, improving mass transfer efficiency by over 30% compared to traditional catalysts.

The hierarchical pore system (macropores enhance mass transfer, mesopores increase active site exposure, and micropores augment specific surface area) optimizes the diffusion of reactants and products, improving mass transfer efficiency by over 30% compared to traditional catalysts.

6. Low Energy Consumption and Operating Cost

Through optimizing the design of the reactor and ozone dosage control systems, water and electricity consumption are reduced to less than 3.5kWh, lowering overall operating costs by 20-30%.

7. Intelligent Integration

Integrated with SINOKLE’s CDOF (Cyclonic Dissolved Ozone Flotation Unit), the system combines hydrodynamic simulation and real-time monitoring to automatically adjust ozone dosing, ensuring efficient mixing and treatment stability.

Ⅱ. Application Field

SINOKLE's heterogeneous ozone catalysts are widely used in the following fields, particularly suitable for treating high-concentration, refractory organic wastewater:

1. Petrochemical Industry

Treatment of refinery wastewater, desalination cutting water, phenolic wastewater, etc., to remove pollutants such as COD, phenols, and cyanides.

Case Study: In a petrochemical project, the use of KHC-PC1001 catalyst reduced COD from 1,000mg/L to below 50mg/L, improving treatment efficiency by 30% and reducing operating costs by 20%.

2. Pharmaceutical and Fine-Chemical Industries

Targeted treatment of highly toxic, refractory organic wastewater (e.g., antibiotics, hormones), achieving advanced oxidation and mineralization to meet the GB 18918-2002 Grade B standards.

Application Scenario: Wastewater treatment in pharmaceutical plants, degrading antibiotic residues to ensure non-toxic effluent.

3. Dyeing and Textile Industries

Treatment of dye wastewater to remove color, odor, and organic pollutants, enhancing wastewater biodegradability and creating favorable conditions for subsequent biological treatment.

4. Municipal Wastewater Treatment

Used for advanced treatment of domestic wastewater to remove organic pollutants and eliminate bacteria, improving effluent quality. Suitable for upgrading the standards of the water treatment plant tailwater.

Case study: Combined with CDOF technology for treating black and odorous water, achieving effluent quality meeting Class IV Surface Water Standards.

5. Other Industrial Wastewater Applications

Suitable for treating high-COD and highly toxic wastewater from industries such as papermaking, leather tanning, and electroplating. Reduces the toxicity of intermediate products and ensures compliance with environmental regulations.

Ⅲ. Comparison with Other Technologies

Compared to homogeneous catalysts, heterogeneous catalysts offer advantages such as no metal leaching, reusability, broader pH adaptability, and lower operating costs.

In contrast to conventional ozone oxidation processes, SINOKLE's ozone catalysts overcome the limitations of low ozone mass transfer efficiency (traditional processes: <60%), incomplete mineralization, and high energy consumption through precise regulation of active sites and a hierarchical pore structure design. This innovation enhances mass transfer efficiency to over 80% and improves COD removal rates by 20%-30%.

Ⅳ. Conclusion

SINOKLE's heterogeneous ozone catalysts are characterized by high activity, broad pH adaptability, no secondary pollution, long lifespan, and low operating costs. Integrated with CDOF technology, the catalysts demonstrate exceptional performance across different industries such as petrochemical, pharmaceutical, textile dyeing, and municipal wastewater treatment. Their innovative design significantly enhances ozone oxidation efficiency, providing a highly effective and green solution for refractory organic wastewater treatment. This enables enterprises to achieve both environmental compliance and economic benefits.